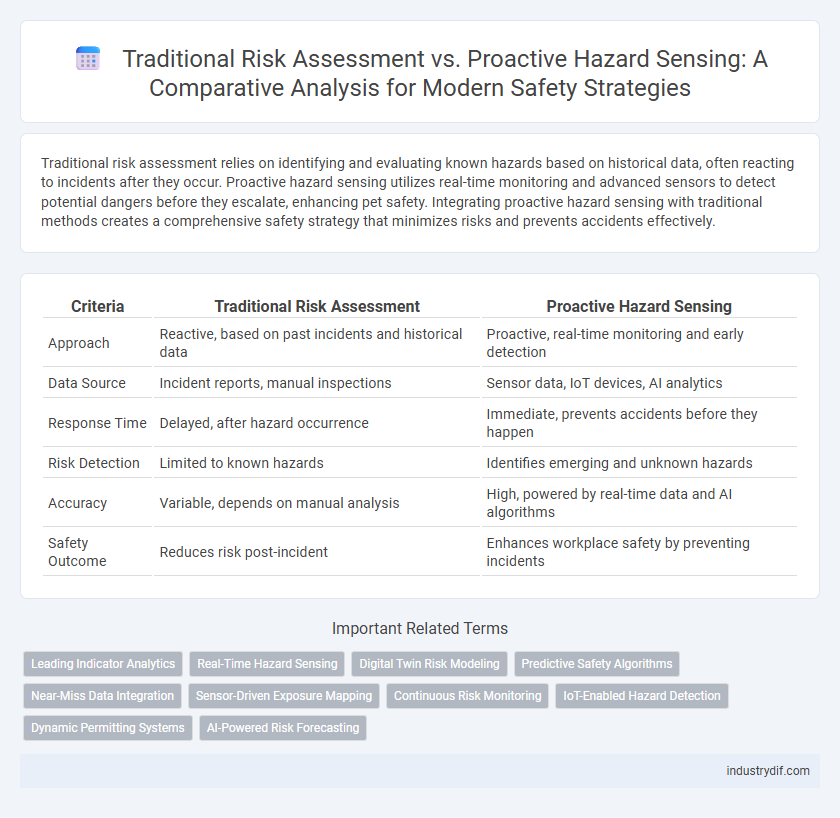

Traditional risk assessment relies on identifying and evaluating known hazards based on historical data, often reacting to incidents after they occur. Proactive hazard sensing utilizes real-time monitoring and advanced sensors to detect potential dangers before they escalate, enhancing pet safety. Integrating proactive hazard sensing with traditional methods creates a comprehensive safety strategy that minimizes risks and prevents accidents effectively.

Table of Comparison

| Criteria | Traditional Risk Assessment | Proactive Hazard Sensing |

|---|---|---|

| Approach | Reactive, based on past incidents and historical data | Proactive, real-time monitoring and early detection |

| Data Source | Incident reports, manual inspections | Sensor data, IoT devices, AI analytics |

| Response Time | Delayed, after hazard occurrence | Immediate, prevents accidents before they happen |

| Risk Detection | Limited to known hazards | Identifies emerging and unknown hazards |

| Accuracy | Variable, depends on manual analysis | High, powered by real-time data and AI algorithms |

| Safety Outcome | Reduces risk post-incident | Enhances workplace safety by preventing incidents |

Introduction to Safety Management Approaches

Traditional risk assessment relies on identifying and evaluating known hazards through historical data and fixed inspection schedules, emphasizing compliance and reactive measures. Proactive hazard sensing employs real-time monitoring technologies, such as IoT sensors and AI analytics, to detect emerging risks before incidents occur. Integrating these advanced safety management approaches enhances hazard identification accuracy and improves overall workplace safety performance.

Defining Traditional Risk Assessment

Traditional Risk Assessment involves systematically identifying and evaluating potential hazards based on historical data and established risk categories. This method relies heavily on probability and severity to prioritize risks, often using checklists and incident reports to predict future incidents. While effective for known hazards, it can be limited by its reactive nature and inability to detect emerging or dynamic risks in real time.

What is Proactive Hazard Sensing?

Proactive Hazard Sensing involves continuous monitoring and early detection of potential safety threats using advanced technologies like sensors, data analytics, and real-time alerts. Unlike traditional risk assessments that rely on periodic evaluations, it enables immediate response to emerging hazards, significantly reducing accident rates and improving workplace safety. This approach integrates predictive analytics and machine learning to anticipate risks before incidents occur, enhancing overall hazard management strategies.

Key Differences in Methodology

Traditional risk assessment relies on historical data and periodic inspections to identify hazards, emphasizing reactive measures based on past incidents. Proactive hazard sensing employs real-time monitoring technologies and predictive analytics to detect potential risks before they manifest, enabling continuous safety improvements. This shift in methodology enhances early detection and dynamic response, reducing workplace accidents and improving overall safety management.

Limitations of Traditional Risk Assessment

Traditional Risk Assessment often relies on historical data and periodic evaluations, which can miss emerging hazards and dynamic workplace conditions. This approach may lead to incomplete hazard identification and delayed response times, increasing the likelihood of accidents. Its reactive nature limits the ability to anticipate and prevent incidents compared to Proactive Hazard Sensing systems.

Advantages of Proactive Hazard Sensing

Proactive Hazard Sensing enhances workplace safety by continuously monitoring environmental and operational conditions to detect potential risks before they escalate, reducing incident rates significantly. Unlike traditional risk assessment, which relies on periodic evaluations and historical data, proactive sensing leverages real-time data analytics and IoT sensors for immediate hazard identification and response. This approach improves hazard visibility, accelerates intervention times, and fosters a safer work environment through predictive maintenance and preventive measures.

Implementation Challenges

Traditional risk assessment often faces implementation challenges due to its reactive nature and reliance on historical data, which can lead to delayed hazard identification and mitigation. Proactive hazard sensing leverages real-time data and advanced analytics, but requires significant investment in technology and skilled personnel for effective deployment. Integrating proactive systems with existing safety protocols demands organizational change management and continuous training to overcome resistance and ensure consistent safety performance.

Industry Adoption Trends

Traditional risk assessment relies heavily on historical data and periodic evaluations, often leading to reactive safety measures in industries like manufacturing and construction. Proactive hazard sensing integrates real-time monitoring technologies, such as IoT sensors and AI analytics, which are increasingly adopted in high-risk sectors including oil and gas, mining, and chemical processing. Industry adoption trends show a strong shift towards proactive systems that reduce incident rates by enabling early hazard detection and continuous risk management.

Case Studies: Real-world Comparisons

Case studies comparing Traditional Risk Assessment versus Proactive Hazard Sensing reveal significant differences in incident reduction and response times. Organizations implementing Proactive Hazard Sensing reported up to a 40% decrease in workplace accidents, driven by real-time monitoring and early hazard detection. Traditional methods often rely on periodic reviews, whereas proactive systems leverage continuous data analytics to mitigate risks before incidents occur.

Future Outlook for Safety Standards

Traditional risk assessment relies heavily on historical data and predefined hazard scenarios, often resulting in reactive safety measures. Proactive hazard sensing leverages real-time data analytics, IoT sensors, and AI-driven predictive models to identify emerging risks before incidents occur. The future of safety standards will likely emphasize continuous monitoring, predictive hazard detection, and adaptive protocols to enhance workplace safety and reduce accidents.

Related Important Terms

Leading Indicator Analytics

Leading indicator analytics in proactive hazard sensing enhances safety by identifying potential risks before incidents occur, unlike traditional risk assessment which relies on historical data and reactive measures. Leveraging real-time data and predictive algorithms, leading indicators enable early intervention, reducing workplace accidents and improving overall hazard management effectiveness.

Real-Time Hazard Sensing

Real-time hazard sensing uses sensors, IoT devices, and AI analytics to continuously monitor and detect potential risks, enabling immediate response to prevent accidents. Traditional risk assessment relies on periodic evaluations and historical data, which may miss emerging hazards and delay intervention.

Digital Twin Risk Modeling

Digital Twin Risk Modeling advances safety by creating dynamic, real-time simulations that surpass Traditional Risk Assessment's static evaluations, enabling continuous hazard detection and mitigation. Integrating sensor data and predictive analytics, Digital Twins proactively identify potential failures, reducing incidents and enhancing operational resilience.

Predictive Safety Algorithms

Traditional risk assessment relies heavily on historical incident data and manual inspections, often resulting in reactive safety measures that identify hazards after they occur. Predictive safety algorithms in proactive hazard sensing utilize real-time data analytics and machine learning to forecast potential risks, enabling early intervention and enhancing overall workplace safety.

Near-Miss Data Integration

Traditional risk assessment often relies on historical incident records and static data, potentially overlooking dynamic workplace hazards. Integrating near-miss data into proactive hazard sensing enhances real-time risk identification and prevention by capturing early warning signs before accidents occur.

Sensor-Driven Exposure Mapping

Traditional risk assessment relies on historical data and manual inspections, often leading to delayed hazard identification. Sensor-driven exposure mapping enables real-time detection and continuous monitoring of environmental risks, significantly enhancing workplace safety through proactive hazard sensing.

Continuous Risk Monitoring

Traditional risk assessments rely on periodic evaluations that may miss emerging threats, whereas proactive hazard sensing enables continuous risk monitoring through real-time data analysis and sensor integration. Continuous risk monitoring enhances workplace safety by detecting hazards promptly, reducing incident response time, and facilitating immediate corrective actions.

IoT-Enabled Hazard Detection

Traditional risk assessment relies on periodic inspections and historical data to identify potential safety risks, often leading to delayed hazard detection. IoT-enabled hazard detection enhances safety by providing real-time monitoring through interconnected sensors, allowing immediate identification and response to dangerous conditions.

Dynamic Permitting Systems

Dynamic permitting systems enhance safety by continuously monitoring workplace conditions and enabling real-time hazard identification, surpassing traditional risk assessments that rely on periodic evaluations. Integrating proactive hazard sensing with these systems allows for immediate adjustments to permits, significantly reducing the likelihood of incidents and improving compliance with safety regulations.

AI-Powered Risk Forecasting

AI-powered risk forecasting enhances traditional risk assessment by leveraging real-time data and predictive analytics to identify potential hazards before they manifest. This proactive hazard sensing approach improves workplace safety by enabling timely interventions and minimizing incident rates through continuous monitoring and machine learning algorithms.

Traditional Risk Assessment vs Proactive Hazard Sensing Infographic

industrydif.com

industrydif.com