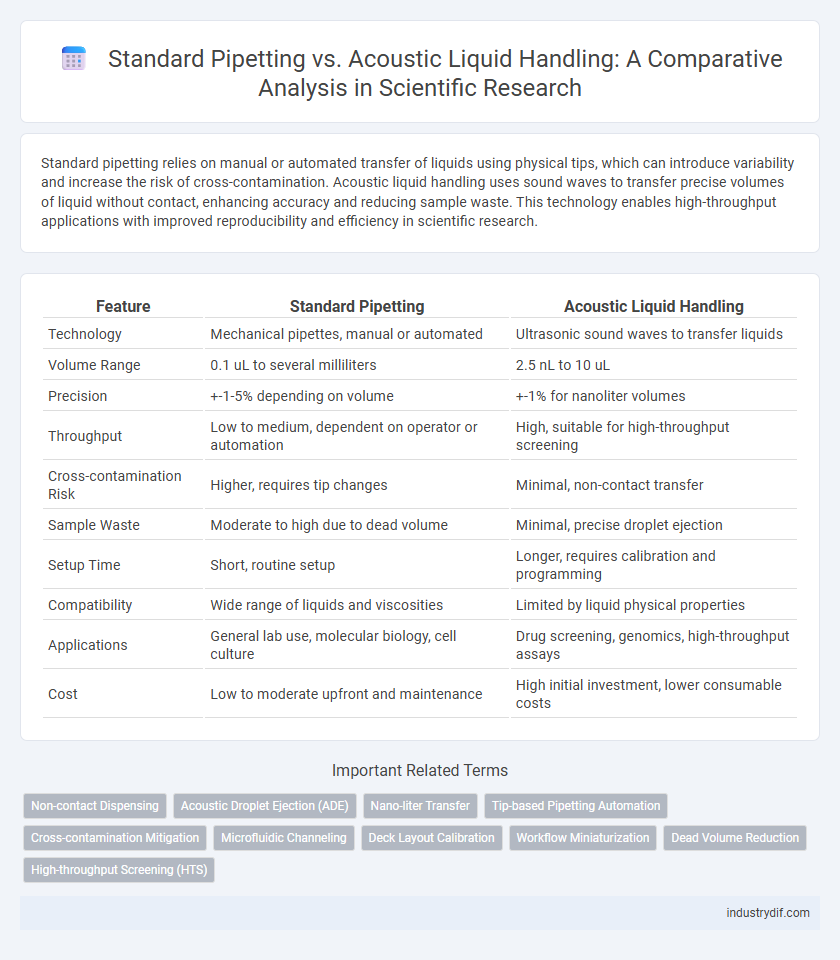

Standard pipetting relies on manual or automated transfer of liquids using physical tips, which can introduce variability and increase the risk of cross-contamination. Acoustic liquid handling uses sound waves to transfer precise volumes of liquid without contact, enhancing accuracy and reducing sample waste. This technology enables high-throughput applications with improved reproducibility and efficiency in scientific research.

Table of Comparison

| Feature | Standard Pipetting | Acoustic Liquid Handling |

|---|---|---|

| Technology | Mechanical pipettes, manual or automated | Ultrasonic sound waves to transfer liquids |

| Volume Range | 0.1 uL to several milliliters | 2.5 nL to 10 uL |

| Precision | +-1-5% depending on volume | +-1% for nanoliter volumes |

| Throughput | Low to medium, dependent on operator or automation | High, suitable for high-throughput screening |

| Cross-contamination Risk | Higher, requires tip changes | Minimal, non-contact transfer |

| Sample Waste | Moderate to high due to dead volume | Minimal, precise droplet ejection |

| Setup Time | Short, routine setup | Longer, requires calibration and programming |

| Compatibility | Wide range of liquids and viscosities | Limited by liquid physical properties |

| Applications | General lab use, molecular biology, cell culture | Drug screening, genomics, high-throughput assays |

| Cost | Low to moderate upfront and maintenance | High initial investment, lower consumable costs |

Introduction to Liquid Handling Technologies

Standard pipetting relies on manual or automated physical aspiration and dispensing of liquids through disposable tips, offering precision for microliter to milliliter volumes but limited by tip contamination and throughput constraints. Acoustic liquid handling utilizes high-frequency sound waves to transfer nanoliter to microliter volumes without contact, enabling non-invasive, tipless dispensing with superior accuracy, reduced cross-contamination, and increased sample throughput. Both technologies serve critical roles in laboratory automation, with acoustic methods transforming high-throughput screening, genomics, and drug discovery by enhancing speed and miniaturization.

Overview of Standard Pipetting Methods

Standard pipetting methods rely on mechanical displacement to transfer precise volumes of liquid using disposable or fixed-tip pipettes, commonly employed in laboratories for their cost-effectiveness and straightforward operation. These techniques typically involve manual aspiration and dispensing, which can introduce variability and contamination risks, especially in high-throughput settings. Despite limitations in speed and automation, standard pipetting remains a fundamental tool for tasks requiring moderate precision and sample handling flexibility.

Principles of Acoustic Liquid Handling

Acoustic liquid handling relies on focused sound waves to transfer liquids without physical contact, enabling precise and contamination-free sample dispensing. This technology uses acoustic energy to eject droplets from a source plate by generating ultrasonic waves that overcome surface tension and eject volumes in the nanoliter range. The non-contact transfer mechanism increases accuracy, reduces cross-contamination, and enhances throughput compared to traditional pipetting techniques.

Precision and Accuracy Comparison

Standard pipetting methods exhibit variability in precision and accuracy due to factors such as operator technique and tip quality, often resulting in volumetric errors of up to +-5%. Acoustic liquid handling technology utilizes sound waves to transfer nanoliter volumes with minimal physical contact, achieving precision levels below 1% coefficient of variation and enhanced accuracy in low-volume dispensing. Comparative studies demonstrate acoustic liquid handling significantly reduces sample contamination risk and improves reproducibility in high-throughput assays compared to traditional pipetting.

Throughput Capabilities in Laboratories

Standard pipetting techniques offer reliable accuracy but are limited by manual or semi-automated processes, restricting throughput in high-volume laboratories. Acoustic liquid handling utilizes sound waves to transfer nanoliter volumes rapidly without contact, significantly increasing sample processing speed and reducing cross-contamination risks. Laboratories implementing acoustic systems can achieve throughput improvements of up to 10-fold compared to conventional pipetting, optimizing workflows for large-scale screening and assays.

Sample Volume and Miniaturization

Standard pipetting typically requires larger sample volumes, often in the microliter to milliliter range, limiting the potential for miniaturization in high-throughput assays. Acoustic liquid handling enables precise transfer of nanoliter to picoliter volumes without physical contact, allowing significant reduction in reagent consumption and increased assay density. This technology supports advanced miniaturization, facilitating cost-effective screening and enhanced sensitivity in scientific research applications.

Contamination Risks and Cross-Contamination Control

Standard pipetting methods pose higher contamination risks due to direct contact between the pipette tip and sample, increasing the chance of cross-contamination. Acoustic liquid handling eliminates physical contact by using focused sound waves to transfer liquids, significantly reducing contamination risk and enhancing cross-contamination control. This non-contact technology ensures higher sample integrity, critical for sensitive scientific applications requiring stringent contamination prevention.

Workflow Automation and Integration

Standard pipetting relies on manual or semi-automated steps, which can introduce variability and limit throughput in high-throughput screening workflows. Acoustic liquid handling technology enables non-contact, precise droplet transfer, significantly enhancing workflow automation and reducing contamination risks in integrated laboratory systems. Integration with robotic platforms and laboratory information management systems (LIMS) facilitates seamless data flow and process standardization, optimizing efficiency in complex experimental setups.

Cost Implications and Resource Efficiency

Standard pipetting requires higher consumable costs due to frequent replacement of tips and increased reagent volumes, leading to elevated operational expenses. Acoustic liquid handling reduces sample waste by enabling non-contact, precise droplet transfer, thereby lowering reagent costs and minimizing contamination risks. Enhanced resource efficiency in acoustic systems contributes to long-term cost savings by decreasing labor time and improving throughput accuracy in high-throughput screening environments.

Future Trends in Liquid Handling Technologies

Future trends in liquid handling technologies emphasize the integration of acoustic liquid handling systems due to their precision, non-contact transfer capabilities, and reduced cross-contamination risk compared to standard pipetting. Innovations in automated acoustic droplet ejection are driving higher throughput screening, miniaturization of assays, and enhanced reproducibility in genomic and proteomic research. Continued development of machine learning algorithms and real-time monitoring promises to optimize liquid handling workflows, accelerating drug discovery and personalized medicine applications.

Related Important Terms

Non-contact Dispensing

Non-contact dispensing in acoustic liquid handling uses focused sound waves to transfer liquids with high precision, eliminating contamination risks common in standard pipetting techniques. This method enhances reproducibility and accuracy in microscale liquid transfers, essential for high-throughput screening and sensitive assays.

Acoustic Droplet Ejection (ADE)

Acoustic Droplet Ejection (ADE) leverages focused sound waves to transfer nanoliter volumes of liquid without physical contact, enabling higher precision and reduced cross-contamination compared to standard pipetting methods. ADE is widely adopted in genomics, drug discovery, and high-throughput screening for its enhanced accuracy, speed, and sample conservation.

Nano-liter Transfer

Standard pipetting methods typically achieve microliter to milliliter volume transfers with limited precision at the nano-liter scale, often resulting in higher sample loss and variability. Acoustic liquid handling enables non-contact, ultra-precise transfer of nano-liter volumes with enhanced reproducibility and minimal cross-contamination, making it ideal for high-throughput screening and genomic applications.

Tip-based Pipetting Automation

Tip-based pipetting automation relies on disposable tips to transfer liquids with high precision, reducing contamination risk and enabling scalable sample processing in high-throughput laboratories. Acoustic liquid handling employs sound waves for contactless droplet transfer, offering ultra-low volume accuracy without tip consumption but requiring specialized equipment and validation for complex biological samples.

Cross-contamination Mitigation

Acoustic liquid handling significantly reduces cross-contamination risks by eliminating direct contact between pipette tips and samples, unlike standard pipetting which relies on disposable tips prone to carryover. This contact-free technology enhances sample integrity and accuracy, particularly in high-throughput screening and sensitive genomic applications.

Microfluidic Channeling

Standard pipetting relies on mechanical displacement to transfer liquids, often causing inconsistencies in microfluidic channeling due to fluid shear stress and air bubble formation. Acoustic liquid handling utilizes focused ultrasonic waves to precisely manipulate nanoliter volumes without physical contact, enhancing uniform flow and reducing the risk of channel clogging in microfluidic systems.

Deck Layout Calibration

Deck layout calibration in standard pipetting requires manual adjustments to ensure precise tip positioning and volume accuracy, often leading to variability and longer setup times. Acoustic liquid handling employs automated deck calibration using ultrasonic sensors and software algorithms, enhancing reproducibility and reducing calibration time by precisely mapping well positions and liquid volumes without physical contact.

Workflow Miniaturization

Acoustic liquid handling enables significant workflow miniaturization by precisely transferring nanoliter-scale volumes without physical contact, reducing reagent consumption and sample waste compared to standard pipetting techniques. This technology enhances assay throughput and reproducibility in scientific research by automating microvolume dispensing with high accuracy.

Dead Volume Reduction

Standard pipetting methods typically incur dead volumes ranging from 5 to 20 microliters due to tip retention and sample adhesion, which limits sample efficiency in low-volume assays. Acoustic liquid handling reduces dead volume to less than 1 microliter by using focused sound waves to transfer droplets directly from source wells, enabling precise and waste-minimized liquid dispensing in high-throughput screening.

High-throughput Screening (HTS)

Standard pipetting in High-throughput Screening (HTS) often faces limitations in precision, speed, and cross-contamination risk, whereas acoustic liquid handling offers non-contact, ultra-low volume dispensing with enhanced accuracy, increased throughput, and reduced reagent consumption. This technology enables miniaturization of assays and improves reproducibility, making it ideal for accelerating drug discovery and biomolecular research.

Standard Pipetting vs Acoustic Liquid Handling Infographic

industrydif.com

industrydif.com