Cargo handling relies heavily on manual labor and traditional equipment, which can limit efficiency and increase the risk of damage and delays. Robotics logistics introduces automated systems that enhance precision, speed, and safety in loading, unloading, and sorting operations. Integrating robotics into cargo handling optimizes supply chain workflows and reduces operational costs through improved accuracy and reduced human error.

Table of Comparison

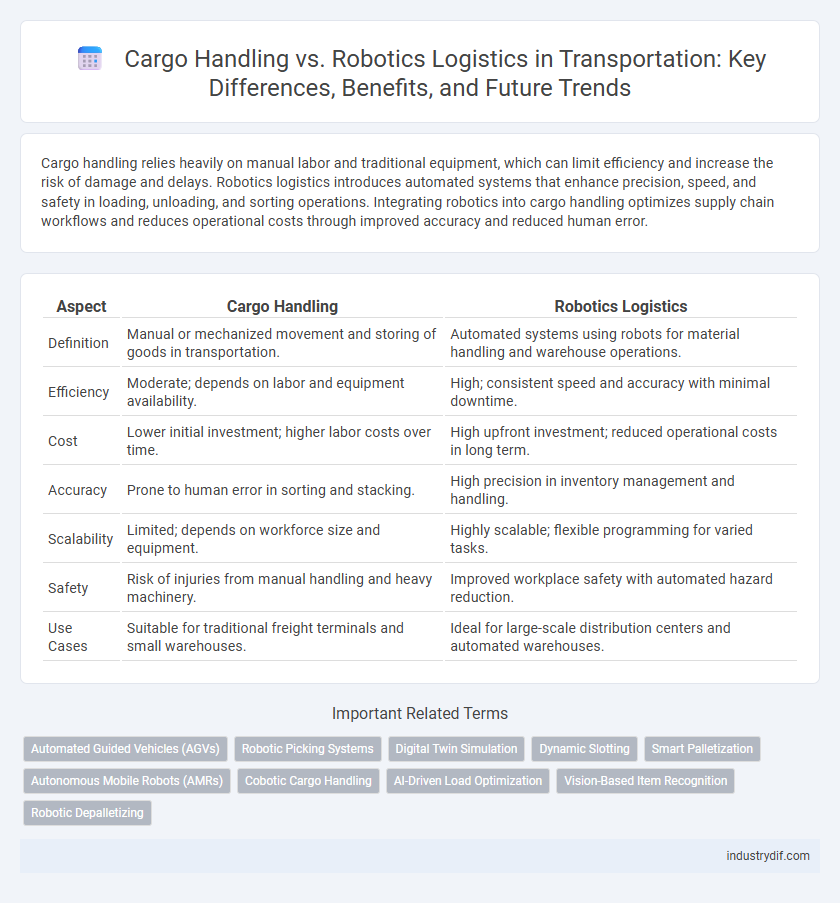

| Aspect | Cargo Handling | Robotics Logistics |

|---|---|---|

| Definition | Manual or mechanized movement and storing of goods in transportation. | Automated systems using robots for material handling and warehouse operations. |

| Efficiency | Moderate; depends on labor and equipment availability. | High; consistent speed and accuracy with minimal downtime. |

| Cost | Lower initial investment; higher labor costs over time. | High upfront investment; reduced operational costs in long term. |

| Accuracy | Prone to human error in sorting and stacking. | High precision in inventory management and handling. |

| Scalability | Limited; depends on workforce size and equipment. | Highly scalable; flexible programming for varied tasks. |

| Safety | Risk of injuries from manual handling and heavy machinery. | Improved workplace safety with automated hazard reduction. |

| Use Cases | Suitable for traditional freight terminals and small warehouses. | Ideal for large-scale distribution centers and automated warehouses. |

Introduction to Cargo Handling and Robotics Logistics

Cargo handling involves the manual and mechanized processes of loading, unloading, storing, and moving goods within transportation hubs, ports, and warehouses. Robotics logistics integrates automated systems and robotic technologies to streamline material handling, increase efficiency, and reduce human error in supply chain operations. Combining traditional cargo handling with robotics enhances precision, accelerates processing times, and optimizes overall freight management in modern transportation networks.

Evolution of Traditional Cargo Handling

Traditional cargo handling has evolved significantly with the integration of robotics logistics, enhancing efficiency and reducing human error in loading and unloading processes. Automation technologies like robotic arms, autonomous guided vehicles (AGVs), and automated storage and retrieval systems (AS/RS) streamline cargo movement, increasing throughput and minimizing turnaround times at ports and warehouses. The shift from manual labor to robotics-enabled logistics reflects a broader trend toward digitization and smart transportation infrastructure.

Robotics Integration in Modern Logistics

Robotics integration in modern logistics revolutionizes cargo handling by automating repetitive and labor-intensive tasks, significantly increasing efficiency and accuracy. Advanced robotic systems enable seamless sorting, loading, and unloading of goods while reducing human error and operational costs. Implementation of AI-driven robots provides real-time inventory tracking and predictive maintenance, optimizing the entire supply chain process.

Key Differences: Manual vs. Robotic Cargo Operations

Manual cargo handling relies heavily on human labor for loading, unloading, and sorting shipments, which can lead to higher risks of injury and inconsistent efficiency. Robotics logistics employs automated systems and robotic arms to manage cargo operations, resulting in higher precision, faster processing times, and reduced operational costs. Key differences include the dependence on human intervention versus autonomous technology, impacting scalability and safety in transportation hubs.

Efficiency and Productivity Comparison

Cargo handling relies heavily on manual labor, often leading to slower processing times and higher error rates in loading and unloading operations. Robotics logistics integrates automated systems such as robotic arms and autonomous guided vehicles, significantly increasing throughput and precision while reducing labor costs. The measurable impact includes a 30-50% boost in efficiency and consistent productivity gains due to continuous, error-minimized workflows.

Safety Considerations in Cargo and Robotics Logistics

Cargo handling involves significant manual labor, increasing the risk of injuries such as musculoskeletal disorders and accidents caused by heavy lifting or equipment misuse. Robotics logistics enhances safety by automating repetitive tasks, reducing human exposure to hazardous environments and minimizing errors through precision and consistency. Integrating robotics in cargo operations leads to improved workplace safety protocols and lower accident rates compared to traditional cargo handling methods.

Cost Implications and ROI Analysis

Cargo handling using traditional methods often incurs higher labor and operational costs compared to robotics logistics, which leverages automation to reduce human error and increase efficiency. Robotics logistics systems require significant upfront investment but deliver faster return on investment (ROI) through decreased labor expenses and improved throughput. Cost implications involve balancing initial capital expenditure against long-term savings, where advanced robotics technologies provide scalable, data-driven optimizations for cargo management and supply chain economics.

Impact on Workforce and Skill Requirements

Cargo handling traditionally relies on manual labor, requiring workers to possess physical strength and basic operational skills, while robotics logistics demands advanced technical expertise in robotics programming, maintenance, and system integration. The shift toward automation reduces the need for low-skilled labor but increases demand for specialized roles such as robotic technicians and data analysts. This transformation leads to workforce reskilling and continual training to adapt to evolving technology-driven logistics environments.

Future Trends in Cargo Handling Automation

Future trends in cargo handling automation emphasize the integration of advanced robotics and AI-driven logistics systems to enhance efficiency and accuracy in freight management. Autonomous vehicles, robotic arms, and smart conveyor systems are increasingly deployed to streamline loading, unloading, and sorting processes, minimizing human error and operational costs. The adoption of Internet of Things (IoT) sensors and machine learning algorithms supports real-time monitoring and predictive maintenance, transforming traditional cargo handling into a fully automated, data-driven ecosystem.

Choosing Between Traditional and Robotic Logistics Solutions

Choosing between traditional cargo handling and robotic logistics solutions depends on factors such as operational scale, accuracy, and cost-efficiency. Robotic logistics enhances precision and speed by automating repetitive tasks, reducing human error, and increasing throughput in warehouses and distribution centers. Traditional cargo handling offers flexibility and lower upfront costs, making it suitable for smaller operations or those requiring manual judgment in complex handling scenarios.

Related Important Terms

Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) revolutionize cargo handling by enhancing logistics efficiency through precise, automated transport of goods within warehouses and distribution centers. These robotics logistics solutions reduce human error, optimize workflow, and enable 24/7 operations, significantly outperforming traditional manual cargo handling methods in speed and accuracy.

Robotic Picking Systems

Robotic picking systems in cargo handling optimize efficiency by automating the selection and sorting of goods with precision and speed, reducing human error and labor costs. These advanced robotics integrate AI and machine learning to enhance real-time inventory management and streamline logistics workflows in warehouses and distribution centers.

Digital Twin Simulation

Digital twin simulation enhances cargo handling by creating precise virtual replicas of logistics processes, enabling real-time monitoring and optimization of robotic systems for increased efficiency. Integrating digital twins in robotics logistics allows predictive maintenance, reduces operational downtime, and optimizes resource allocation through data-driven insights.

Dynamic Slotting

Dynamic slotting in cargo handling optimizes warehouse space by using real-time data to assign storage locations based on cargo size, weight, and frequency of movement, enhancing efficiency and reducing retrieval time. Robotics logistics leverages automated guided vehicles and robotic arms to implement dynamic slotting with higher precision and speed, minimizing human error and increasing overall throughput in distribution centers.

Smart Palletization

Smart palletization in cargo handling leverages robotics logistics to optimize load stability, reduce manual labor, and enhance throughput efficiency by automatically arranging goods based on size, weight, and destination. This integration improves supply chain accuracy and lowers operational costs through precise, real-time data analysis and adaptable robotic systems.

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) revolutionize cargo handling by increasing efficiency and accuracy in logistics operations, reducing human labor costs and minimizing errors in inventory management. These robots navigate dynamically within warehouses, adapting to changing environments and streamlining the transport of goods, thus enhancing overall supply chain productivity.

Cobotic Cargo Handling

Cobotic cargo handling integrates collaborative robots with human operators to optimize efficiency, safety, and precision in transportation logistics. This approach reduces manual labor errors, accelerates loading and unloading processes, and enhances supply chain reliability in cargo operations.

AI-Driven Load Optimization

AI-driven load optimization enhances cargo handling by utilizing robotics logistics systems that precisely calculate weight distribution, space utilization, and handling sequences, reducing manual errors and improving operational efficiency. These intelligent algorithms analyze real-time data to optimize loading plans, increase throughput, and minimize damage during transportation processes.

Vision-Based Item Recognition

Vision-based item recognition in cargo handling significantly enhances accuracy and efficiency by enabling automated identification and sorting of packages, reducing human error and operational delays. Robotics logistics integrated with advanced vision systems facilitates real-time tracking and precise manipulation of diverse cargo, optimizing supply chain workflows and improving overall throughput.

Robotic Depalletizing

Robotic depalletizing in logistics significantly enhances cargo handling efficiency by automating the unloading of goods from pallets, reducing labor costs and minimizing product damage. Advanced vision systems and AI integration enable robots to adapt to varied package sizes and weights, optimizing throughput in warehouses and distribution centers.

Cargo Handling vs Robotics Logistics Infographic

industrydif.com

industrydif.com