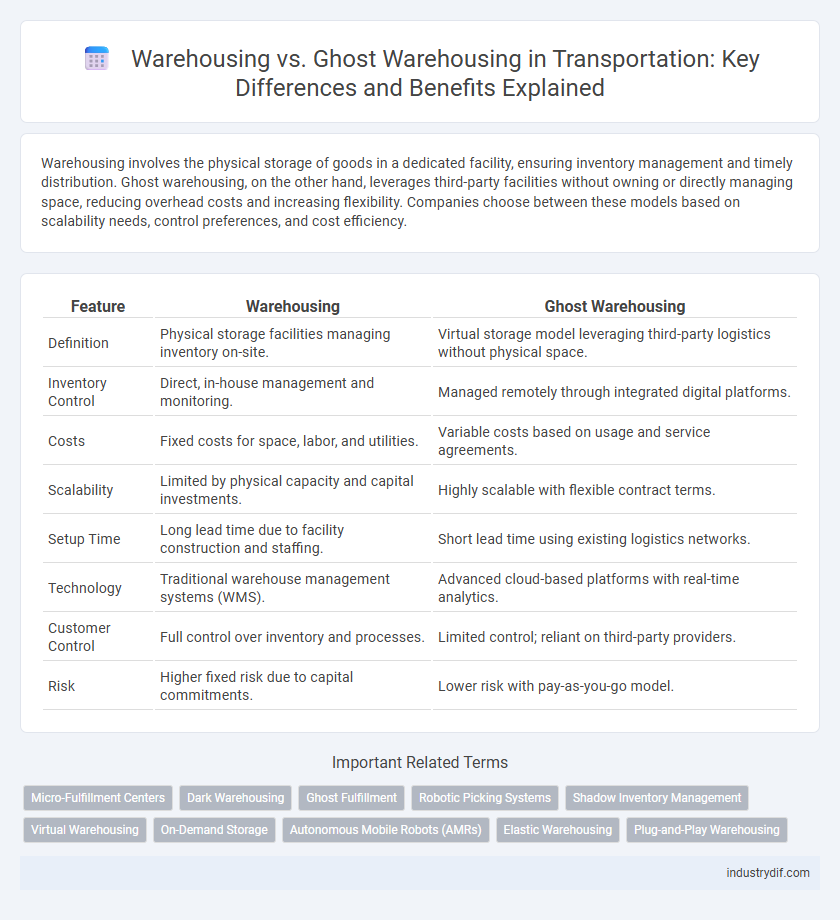

Warehousing involves the physical storage of goods in a dedicated facility, ensuring inventory management and timely distribution. Ghost warehousing, on the other hand, leverages third-party facilities without owning or directly managing space, reducing overhead costs and increasing flexibility. Companies choose between these models based on scalability needs, control preferences, and cost efficiency.

Table of Comparison

| Feature | Warehousing | Ghost Warehousing |

|---|---|---|

| Definition | Physical storage facilities managing inventory on-site. | Virtual storage model leveraging third-party logistics without physical space. |

| Inventory Control | Direct, in-house management and monitoring. | Managed remotely through integrated digital platforms. |

| Costs | Fixed costs for space, labor, and utilities. | Variable costs based on usage and service agreements. |

| Scalability | Limited by physical capacity and capital investments. | Highly scalable with flexible contract terms. |

| Setup Time | Long lead time due to facility construction and staffing. | Short lead time using existing logistics networks. |

| Technology | Traditional warehouse management systems (WMS). | Advanced cloud-based platforms with real-time analytics. |

| Customer Control | Full control over inventory and processes. | Limited control; reliant on third-party providers. |

| Risk | Higher fixed risk due to capital commitments. | Lower risk with pay-as-you-go model. |

Introduction to Warehousing in Transportation

Warehousing in transportation involves the storage and management of goods within strategically located facilities to ensure efficient distribution and inventory control. Conventional warehousing requires physical space, equipment, and staff to handle receiving, storing, and dispatching products. Ghost warehousing leverages third-party spaces and technology to optimize storage without owning physical infrastructure, enhancing flexibility and reducing operational costs.

Defining Traditional Warehousing

Traditional warehousing involves the use of physical storage facilities where goods are received, stored, and dispatched, supporting inventory management and order fulfillment processes. These warehouses often include infrastructure for handling, packaging, and tracking products, ensuring efficient supply chain operations. Unlike ghost warehousing, traditional warehouses maintain a tangible presence with dedicated space, equipment, and staff to manage inventory on-site.

What is Ghost Warehousing?

Ghost warehousing refers to a modern logistics model where companies utilize third-party warehouse spaces without maintaining a physical or dedicated facility of their own. Unlike traditional warehousing, ghost warehousing leverages digital platforms to manage inventory remotely, enabling scalable, cost-efficient storage solutions. This approach optimizes supply chain flexibility and reduces overhead by renting modular space on-demand through a network of shared warehouses.

Key Differences Between Warehousing and Ghost Warehousing

Warehousing involves the physical storage of goods in a dedicated facility managed by the owner or a third party, with direct inventory control and onsite staff for handling and distribution. Ghost warehousing operates as a virtual fulfillment center without a physical inventory, relying on third-party suppliers to ship products directly to customers, minimizing overhead and storage costs. Key differences include inventory ownership, physical presence, and operational control, where traditional warehousing provides hands-on management, while ghost warehousing emphasizes flexibility and reduced investment in infrastructure.

Operational Models: Warehousing vs Ghost Warehousing

Traditional warehousing involves physically storing inventory in a centralized facility, enabling direct control over stock management, order fulfillment, and shipping processes. Ghost warehousing operates as a virtual fulfillment model, relying on third-party logistics providers and decentralized inventory locations to optimize flexibility and reduce overhead costs. The operational model of ghost warehousing enhances scalability and responsiveness by leveraging distributed networks, while traditional warehouses prioritize inventory consolidation and in-house logistical coordination.

Advantages of Traditional Warehousing

Traditional warehousing offers centralized inventory management, enabling precise stock control and efficient order fulfillment. Physical storage facilities provide enhanced security, allowing businesses to monitor goods and minimize losses through theft or damage. Bulk storage capacity supports large-scale operations, reducing overall logistics costs by consolidating shipments and streamlining distribution processes.

Benefits of Ghost Warehousing Solutions

Ghost warehousing solutions optimize supply chain efficiency by eliminating the need for physical storage spaces, significantly reducing overhead costs associated with rent, utilities, and maintenance. These virtual warehouses leverage real-time inventory management systems to provide flexible, scalable storage options that adapt to fluctuating demand without the constraints of fixed-location warehousing. Companies benefit from enhanced operational agility, improved order fulfillment speed, and minimized capital investment, making ghost warehousing an ideal strategy for modern e-commerce and logistics businesses.

Cost Comparison: Warehousing vs Ghost Warehousing

Traditional warehousing often incurs higher operational expenses due to fixed costs like facility maintenance, utilities, and staff salaries, whereas ghost warehousing significantly reduces overhead by utilizing shared spaces and flexible contracts. Cost efficiency in ghost warehousing emerges from pay-as-you-go models, eliminating long-term leases and allowing businesses to scale storage needs dynamically. Comparing both, ghost warehousing offers substantial savings in upfront and ongoing costs, making it a preferred option for companies seeking agile and cost-effective inventory management solutions.

Industry Trends Shaping Warehousing Models

Industry trends reveal a growing preference for ghost warehousing due to its cost efficiency and scalability compared to traditional warehousing. Advances in automation, AI-driven inventory management, and on-demand storage solutions empower ghost warehouses to optimize space utilization and reduce operational expenses. Supply chain digitization accelerates this shift by enabling real-time data analytics and seamless integration with e-commerce platforms.

Choosing the Right Warehousing Strategy for Logistics

Selecting the optimal warehousing strategy is crucial for efficient logistics management, balancing costs, and meeting delivery timelines. Traditional warehousing offers control over inventory and storage but requires significant capital investment and operational costs, while ghost warehousing leverages third-party facilities, providing flexibility and scalability with reduced overhead. Analyzing factors such as shipment volume, product types, geographic distribution, and service level agreements helps determine whether owning warehouse space or outsourcing to ghost warehouses maximizes supply chain agility and customer satisfaction.

Related Important Terms

Micro-Fulfillment Centers

Micro-fulfillment centers optimize last-mile delivery by leveraging automation and proximity to urban consumers, contrasting traditional warehousing's larger, centralized footprint. Ghost warehousing enhances this model by utilizing underused retail or commercial spaces to increase inventory accessibility and reduce transportation costs.

Dark Warehousing

Dark warehousing, a form of ghost warehousing, optimizes inventory management by operating fully automated facilities with minimal human presence, significantly reducing operational costs and increasing efficiency compared to traditional warehousing. These dark warehouses leverage advanced robotics and real-time data analytics to streamline order fulfillment processes, meeting the growing demand for faster delivery in e-commerce and supply chain logistics.

Ghost Fulfillment

Ghost warehousing leverages third-party facilities and technology to manage inventory invisibly, enabling businesses to fulfill orders without owning physical warehouse space and reducing overhead costs. This ghost fulfillment model streamlines supply chain operations by integrating real-time data and automated processes, enhancing delivery speed and flexibility compared to traditional warehousing.

Robotic Picking Systems

Robotic picking systems in traditional warehousing enable automated item retrieval within physical storage facilities, improving accuracy and efficiency through integrated robotics and AI. Ghost warehousing leverages these robotic systems remotely by managing inventory and order fulfillment through third-party networks without owning physical space, reducing overhead costs and expanding scalability.

Shadow Inventory Management

Shadow inventory management in traditional warehousing involves holding excess stock in physical warehouses, increasing storage costs and reducing agility. Ghost warehousing leverages virtual inventory tracking across decentralized supply chains, optimizing fulfillment speed and minimizing capital tied up in physical stock.

Virtual Warehousing

Virtual warehousing offers a cost-effective alternative to traditional warehousing by leveraging digital platforms to manage inventory without the need for physical storage space, enhancing supply chain flexibility and reducing overhead costs. Ghost warehousing, a subset of virtual warehousing, utilizes third-party logistics providers' existing facilities to store and distribute goods, enabling businesses to scale quickly while minimizing capital investment.

On-Demand Storage

On-demand storage in warehousing offers flexible space allocation, reducing fixed costs and improving inventory management efficiency. Ghost warehousing leverages this model by utilizing underused third-party facilities, enabling scalable storage solutions without long-term commitments or capital investment.

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) enhance efficiency in traditional warehousing by enabling dynamic inventory management and real-time order fulfillment, while ghost warehousing leverages AMRs within automated, unmanned facilities to maximize space utilization and reduce labor costs. The integration of AMRs in ghost warehousing revolutionizes supply chains by increasing speed, accuracy, and scalability in high-volume distribution centers.

Elastic Warehousing

Elastic warehousing adapts storage capacity dynamically based on demand fluctuations, unlike traditional warehousing with fixed space, enabling cost efficiency and scalability. Ghost warehousing leverages third-party facilities without owning physical infrastructure, optimizing supply chains through flexible, on-demand inventory management.

Plug-and-Play Warehousing

Plug-and-play warehousing offers businesses flexible storage solutions by enabling instant access to warehousing space without long-term commitments, contrasting with traditional warehousing that requires upfront investment and fixed leases. Ghost warehousing leverages third-party logistics providers to manage inventory invisibly, streamlining operations and reducing overhead while maintaining control over distribution channels.

Warehousing vs Ghost Warehousing Infographic

industrydif.com

industrydif.com