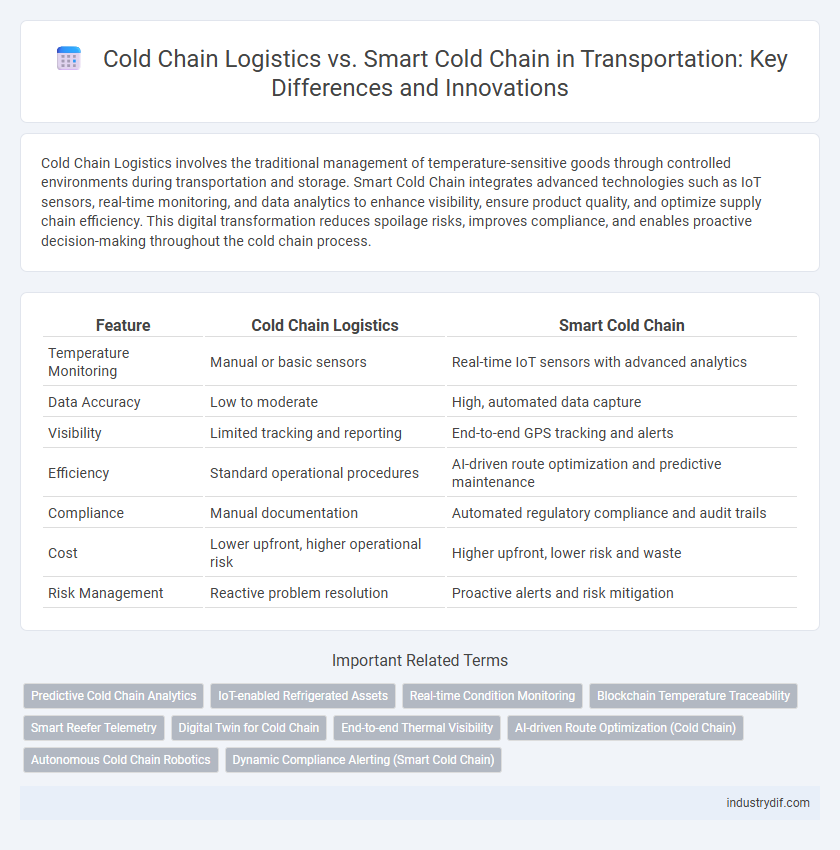

Cold Chain Logistics involves the traditional management of temperature-sensitive goods through controlled environments during transportation and storage. Smart Cold Chain integrates advanced technologies such as IoT sensors, real-time monitoring, and data analytics to enhance visibility, ensure product quality, and optimize supply chain efficiency. This digital transformation reduces spoilage risks, improves compliance, and enables proactive decision-making throughout the cold chain process.

Table of Comparison

| Feature | Cold Chain Logistics | Smart Cold Chain |

|---|---|---|

| Temperature Monitoring | Manual or basic sensors | Real-time IoT sensors with advanced analytics |

| Data Accuracy | Low to moderate | High, automated data capture |

| Visibility | Limited tracking and reporting | End-to-end GPS tracking and alerts |

| Efficiency | Standard operational procedures | AI-driven route optimization and predictive maintenance |

| Compliance | Manual documentation | Automated regulatory compliance and audit trails |

| Cost | Lower upfront, higher operational risk | Higher upfront, lower risk and waste |

| Risk Management | Reactive problem resolution | Proactive alerts and risk mitigation |

Introduction to Cold Chain Logistics

Cold chain logistics ensures the temperature-controlled supply chain critical for preserving perishable goods such as pharmaceuticals, food, and chemicals during storage and transportation. This system relies on insulated packaging, refrigerated vehicles, and temperature monitoring devices to prevent spoilage and maintain product integrity. Smart cold chain enhances this process through IoT sensors, real-time tracking, and data analytics, enabling proactive management and improved efficiency.

Defining Smart Cold Chain Solutions

Smart cold chain solutions integrate IoT sensors, real-time temperature monitoring, and AI-driven analytics to ensure precise control over perishable goods during transportation. These advanced systems enhance traceability, reduce spoilage rates by up to 30%, and optimize route efficiency through predictive maintenance and automated alerts. By leveraging cloud-based platforms, smart cold chains enable seamless data sharing across stakeholders, improving overall supply chain transparency and compliance with regulatory standards.

Key Components of Traditional Cold Chain

Traditional cold chain logistics rely on insulated containers, refrigerated trucks, and temperature-controlled storage facilities to maintain product integrity. Key components include passive cooling systems such as ice packs and gel packs, mechanical refrigeration units, and manual temperature monitoring devices. These elements collectively ensure a stable environment for perishable goods but lack real-time tracking and data analytics featured in smart cold chain solutions.

Technologies Powering Smart Cold Chain

Smart Cold Chain logistics leverage IoT sensors, real-time GPS tracking, and blockchain technology to ensure precise temperature control and traceability throughout the supply chain. Advanced AI algorithms analyze data collected from smart sensors to predict potential disruptions and optimize route planning, enhancing product quality and delivery efficiency. Integration of cloud computing platforms enables seamless data sharing among stakeholders, promoting transparency and proactive decision-making in temperature-sensitive transportation.

Temperature Monitoring: Manual vs IoT-Based

Traditional Cold Chain Logistics relies on manual temperature monitoring using handheld devices and periodic checks, which increases the risk of human error and data gaps. Smart Cold Chain systems utilize IoT-based sensors and real-time data transmission to provide continuous, accurate temperature monitoring along the entire transportation route. This automation enhances product safety and compliance by enabling immediate alerts and corrective actions when temperature deviations occur.

Efficiency and Cost Comparison

Cold Chain Logistics traditionally rely on manual monitoring and standardized temperature controls, often resulting in higher operational costs and less precise efficiency. Smart Cold Chain integrates IoT sensors and real-time data analytics, significantly enhancing temperature accuracy and reducing waste, which lowers overall expenses. Implementing Smart Cold Chain solutions leads to up to 30% cost savings and improved delivery reliability compared to conventional Cold Chain Logistics.

Real-Time Data and Traceability

Cold chain logistics relies on maintaining temperature-controlled environments throughout the supply chain, but often lacks real-time monitoring capabilities. Smart cold chain integrates IoT sensors and advanced analytics to provide continuous, real-time temperature data and precise traceability of perishable goods. This enhances product safety, reduces spoilage, and ensures compliance with regulatory standards through comprehensive data transparency.

Regulatory Compliance and Safety

Cold Chain Logistics requires stringent adherence to regulatory standards such as FDA and EMA guidelines to maintain temperature-sensitive products' integrity throughout transportation. Smart Cold Chain integrates IoT sensors and real-time monitoring systems to enhance compliance by providing continuous temperature data and automated alerts for deviations. This technological advancement significantly improves safety by minimizing the risk of spoilage and ensuring timely interventions during the logistics process.

Sustainability in Cold Chain Operations

Cold Chain Logistics traditionally relies on temperature-controlled storage and transportation to preserve perishable goods, often resulting in high energy consumption and carbon emissions. Smart Cold Chain integrates IoT sensors, real-time data analytics, and automated temperature controls to optimize energy use, reduce waste, and enhance sustainability. Implementing smart technologies in cold chain operations significantly lowers greenhouse gas emissions and improves resource efficiency across the supply chain.

Future Trends in Cold Chain Logistics

Future trends in cold chain logistics emphasize the integration of smart technologies such as IoT sensors, blockchain, and AI-driven analytics to enhance real-time monitoring and predictive maintenance. Smart cold chain systems enable optimized temperature control, reduce spoilage, and improve traceability across pharmaceutical, food, and chemical supply chains. Advancements in automation and data connectivity are transforming traditional cold chain logistics into intelligent, adaptive networks that ensure safety, compliance, and sustainability.

Related Important Terms

Predictive Cold Chain Analytics

Predictive cold chain analytics leverages real-time data and AI algorithms to forecast temperature fluctuations and potential disruptions in cold chain logistics, enhancing product safety and reducing spoilage. Smart cold chain systems integrate IoT sensors and predictive analytics, enabling proactive decision-making that optimizes storage conditions and transportation routes compared to traditional cold chain methods.

IoT-enabled Refrigerated Assets

IoT-enabled refrigerated assets in smart cold chain logistics enhance temperature monitoring, real-time tracking, and predictive maintenance, significantly reducing spoilage and improving supply chain efficiency. Unlike traditional cold chain logistics, smart cold chain leverages connected sensors and data analytics to optimize refrigerated transport conditions dynamically.

Real-time Condition Monitoring

Real-time condition monitoring in smart cold chain logistics enables continuous tracking of temperature, humidity, and location data through IoT sensors, ensuring optimal preservation of perishable goods during transportation. Unlike traditional cold chain logistics, which relies on periodic manual checks, smart cold chains provide immediate alerts for deviations, reducing spoilage risks and enhancing supply chain transparency.

Blockchain Temperature Traceability

Cold chain logistics traditionally rely on manual temperature monitoring methods, which often result in data discrepancies and delays in reporting. Smart cold chain systems integrate blockchain technology to ensure real-time temperature traceability, providing immutable records that enhance product safety and compliance throughout transportation.

Smart Reefer Telemetry

Smart reefer telemetry significantly enhances cold chain logistics by providing real-time monitoring of temperature, humidity, and location data, ensuring optimal conditions for perishable goods throughout transit. This advanced technology reduces spoilage, improves regulatory compliance, and increases operational efficiency compared to traditional cold chain systems lacking continuous data insights.

Digital Twin for Cold Chain

Digital Twin technology in Smart Cold Chain logistics offers real-time monitoring and predictive analytics, enhancing temperature control and minimizing spoilage in perishable goods transport. Compared to traditional Cold Chain logistics, this digital integration improves asset utilization and enables proactive maintenance, ensuring higher efficiency and compliance with safety standards.

End-to-end Thermal Visibility

Cold Chain Logistics traditionally relies on temperature-controlled transportation and storage to maintain product integrity, with limited real-time monitoring capabilities. Smart Cold Chain enhances end-to-end thermal visibility through IoT sensors and advanced analytics, enabling continuous temperature tracking and proactive risk management across the entire supply chain.

AI-driven Route Optimization (Cold Chain)

AI-driven route optimization in cold chain logistics significantly enhances the efficiency of temperature-sensitive goods transportation by analyzing real-time data to reduce delays and fuel consumption. Smart cold chain systems leverage machine learning algorithms to dynamically adjust delivery routes, ensuring optimal preservation of perishable products and minimizing waste.

Autonomous Cold Chain Robotics

Autonomous cold chain robotics enhance smart cold chain logistics by enabling precise temperature control, real-time monitoring, and automated handling of perishable goods, significantly reducing spoilage and operational costs. These advanced robotic systems integrate IoT sensors and AI-driven analytics to optimize route planning and inventory management within cold storage environments.

Dynamic Compliance Alerting (Smart Cold Chain)

Dynamic Compliance Alerting in Smart Cold Chain logistics leverages real-time data analytics and IoT sensors to continuously monitor temperature, humidity, and regulatory standards, ensuring immediate notifications of deviations. This innovation reduces spoilage risk, enhances regulatory adherence, and optimizes supply chain efficiency compared to traditional Cold Chain Logistics.

Cold Chain Logistics vs Smart Cold Chain Infographic

industrydif.com

industrydif.com