Rail automation significantly enhances the efficiency, safety, and reliability of railway systems by integrating advanced sensors, AI, and real-time monitoring technologies. Manual railway operations often face challenges such as human error and slower response times, which automation effectively mitigates. The adoption of rail automation leads to optimized scheduling, reduced operational costs, and improved passenger experience through seamless and precise control of train movements.

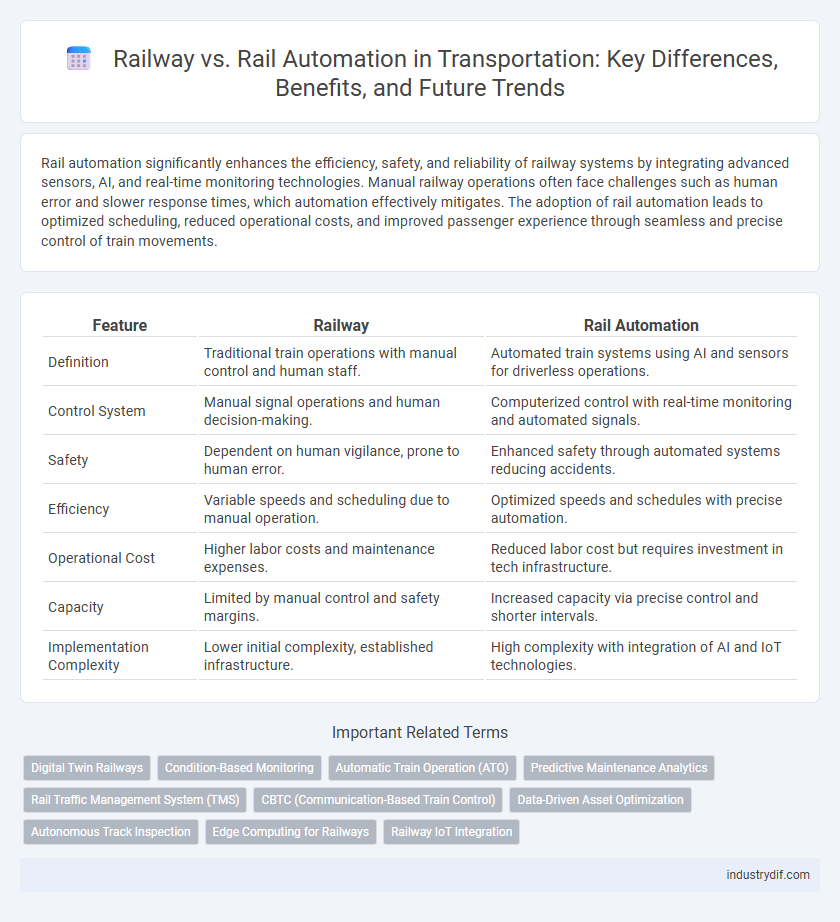

Table of Comparison

| Feature | Railway | Rail Automation |

|---|---|---|

| Definition | Traditional train operations with manual control and human staff. | Automated train systems using AI and sensors for driverless operations. |

| Control System | Manual signal operations and human decision-making. | Computerized control with real-time monitoring and automated signals. |

| Safety | Dependent on human vigilance, prone to human error. | Enhanced safety through automated systems reducing accidents. |

| Efficiency | Variable speeds and scheduling due to manual operation. | Optimized speeds and schedules with precise automation. |

| Operational Cost | Higher labor costs and maintenance expenses. | Reduced labor cost but requires investment in tech infrastructure. |

| Capacity | Limited by manual control and safety margins. | Increased capacity via precise control and shorter intervals. |

| Implementation Complexity | Lower initial complexity, established infrastructure. | High complexity with integration of AI and IoT technologies. |

Overview of Traditional Railway Systems

Traditional railway systems rely on manual signaling, fixed block tracks, and human-operated control centers to manage train movements. These systems often face limitations in capacity, safety, and efficiency due to slower response times and higher dependency on human intervention. Infrastructure includes physical signals, track circuits, and mechanical switches designed for conventional rail operations without digital integration.

Defining Rail Automation Technologies

Rail automation technologies encompass advanced systems such as Positive Train Control (PTC), Automatic Train Operation (ATO), and sensor-based track monitoring, which enhance safety, efficiency, and operational reliability compared to traditional railway methods. These technologies rely on real-time data processing, wireless communication, and AI-driven decision-making to manage train movements and maintenance proactively. Implementing rail automation reduces human error, optimizes scheduling, and supports predictive maintenance, transforming conventional railways into smart transportation networks.

Key Differences: Manual vs Automated Operations

Manual railway operations rely heavily on human intervention for tasks such as signal control, train dispatching, and track switching, which can lead to variability in efficiency and safety. Rail automation integrates advanced technologies like AI-driven control systems, sensors, and real-time data analytics to streamline operations, reduce human error, and enhance precision. Automated rail systems typically offer higher reliability, faster response times, and improved capacity management compared to traditional manual railways.

Benefits of Railway Automation

Railway automation enhances operational efficiency by reducing human error and enabling real-time monitoring of track conditions and train performance. Automated systems improve safety through precise control of signaling and train speeds, minimizing the risk of accidents. Cost savings arise from decreased labor expenses and optimized energy consumption, making railway automation a vital advancement for modern transportation networks.

Safety Improvements in Automated Railways

Automated railways significantly enhance safety by reducing human error through advanced sensor networks and real-time monitoring systems. Integration of AI-driven predictive maintenance minimizes the risk of mechanical failures, ensuring continuous operational safety. Automated control systems also enforce strict adherence to speed limits and signaling, preventing accidents and improving overall railway safety.

Operational Efficiency: Human vs Automation

Rail automation significantly enhances operational efficiency by reducing human error and enabling consistent, high-speed train management, resulting in improved punctuality and safety. Human-operated railway systems rely heavily on manual decision-making and experience, which can introduce variability and slower response times during disruptions. Automated systems optimize scheduling, real-time monitoring, and maintenance processes, leading to cost savings and increased network capacity.

Cost Considerations: Investment and ROI

Railway infrastructure requires significant upfront investment in tracks, stations, and rolling stock, with ongoing maintenance costs that impact long-term financial sustainability. Rail automation systems, including advanced signaling and driverless technology, demand higher initial capital expenditure but offer substantial reductions in operational costs through improved efficiency and lower labor expenses. The return on investment (ROI) for rail automation is accelerated by increased safety, reliability, and capacity, ultimately enhancing economic viability in densely populated and high-traffic corridors.

Challenges in Implementing Rail Automation

Implementing rail automation faces significant challenges including high initial investment costs, integration complexities with existing railway infrastructure, and ensuring safety and reliability standards. Addressing cybersecurity threats and managing workforce transitions are critical for successful automation deployment. Effective collaboration between technology providers, regulators, and railway operators is essential to overcome these obstacles.

Future Trends in Rail Transportation

Rail automation is revolutionizing the future of rail transportation by enhancing operational efficiency, safety, and capacity through advanced technologies like AI-driven signaling systems and autonomous trains. Investments in smart infrastructure and sensor networks enable predictive maintenance, reducing downtime and costs compared to traditional railway operations. The integration of Internet of Things (IoT) devices and real-time data analytics positions rail automation as a key driver in achieving sustainable, high-performance transportation networks globally.

Impact of Automation on Railway Workforce

Rail automation significantly transforms the railway workforce by shifting roles from manual operations to advanced monitoring and maintenance of automated systems. Skilled workers are increasingly required to manage sophisticated technologies such as AI-based signaling, predictive analytics, and autonomous train control. This transition enhances safety and efficiency while necessitating comprehensive retraining and workforce adaptation strategies within the transportation sector.

Related Important Terms

Digital Twin Railways

Digital Twin Railways leverage advanced simulation and real-time data integration to optimize railway operations, predict maintenance needs, and enhance safety through virtual replicas of physical rail networks. This rail automation technology significantly reduces downtime and operational costs compared to traditional railway systems by enabling proactive asset management and dynamic decision-making.

Condition-Based Monitoring

Condition-Based Monitoring in railway systems enhances safety and efficiency by continuously assessing track and train component conditions using sensors and real-time data analytics. Rail automation leverages this monitoring to enable predictive maintenance, reducing downtime and operational costs while ensuring optimal performance.

Automatic Train Operation (ATO)

Automatic Train Operation (ATO) enhances railway efficiency by automating speed regulation, door operation, and precise station stopping, reducing human error and improving safety. Rail automation systems integrate ATO with signaling and communication networks to optimize train schedules, increase capacity, and lower operational costs.

Predictive Maintenance Analytics

Rail automation leverages predictive maintenance analytics to monitor real-time sensor data, enabling early detection of equipment failures and minimizing downtime in railway operations. Advanced machine learning algorithms analyze historical and operational data to optimize maintenance schedules, enhancing safety and reducing costs compared to traditional railway maintenance methods.

Rail Traffic Management System (TMS)

Rail Traffic Management Systems (TMS) enhance railway operations by integrating real-time data, automated scheduling, and predictive maintenance to optimize train movement and reduce delays. Advanced rail automation through TMS enables improved safety, increased network capacity, and seamless communication between control centers and trains.

CBTC (Communication-Based Train Control)

Communication-Based Train Control (CBTC) revolutionizes railway operations by enabling real-time train position monitoring and precise movement control, significantly enhancing safety and line capacity compared to traditional fixed-block signaling systems. Rail automation through CBTC reduces headways, optimizes train scheduling, and supports driverless train operations, driving higher efficiency and reliability in urban transit networks.

Data-Driven Asset Optimization

Rail automation enhances data-driven asset optimization by leveraging real-time sensor data and predictive analytics to monitor track conditions, rolling stock performance, and maintenance needs, reducing downtime and operational costs. Advanced railway systems integrate IoT devices and AI algorithms to optimize scheduling, energy consumption, and asset utilization, driving efficiency and safety improvements across the transportation network.

Autonomous Track Inspection

Autonomous track inspection leverages advanced sensors, AI, and robotics to enhance railway safety and operational efficiency by detecting track defects with greater accuracy and speed compared to traditional manual inspections. This automated approach reduces human error, lowers maintenance costs, and enables real-time monitoring, significantly improving the reliability of railway infrastructure.

Edge Computing for Railways

Rail automation leverages edge computing to enhance real-time data processing directly on trains and along tracks, reducing latency and improving safety and operational efficiency. Integrating edge devices with railway systems supports predictive maintenance and dynamic scheduling, optimizing the overall performance of rail networks.

Railway IoT Integration

Railway IoT integration enhances operational efficiency by enabling real-time asset tracking, predictive maintenance, and automated signaling systems, reducing downtime and improving safety. This smart connectivity in rail automation transforms traditional railways into intelligent networks, optimizing traffic management and energy consumption.

Railway vs Rail Automation Infographic

industrydif.com

industrydif.com