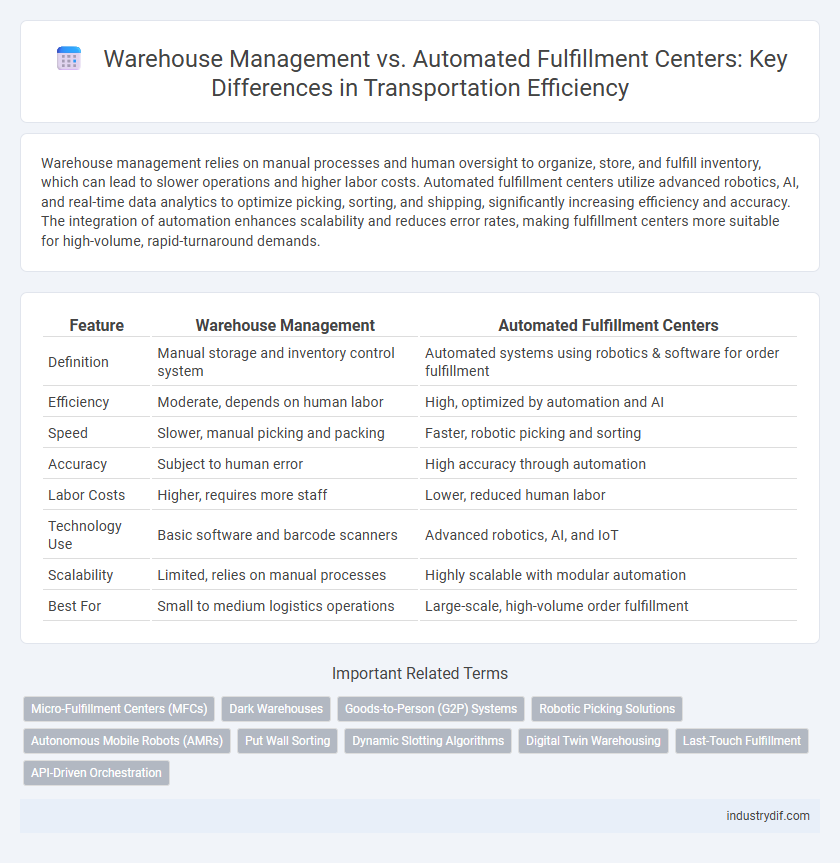

Warehouse management relies on manual processes and human oversight to organize, store, and fulfill inventory, which can lead to slower operations and higher labor costs. Automated fulfillment centers utilize advanced robotics, AI, and real-time data analytics to optimize picking, sorting, and shipping, significantly increasing efficiency and accuracy. The integration of automation enhances scalability and reduces error rates, making fulfillment centers more suitable for high-volume, rapid-turnaround demands.

Table of Comparison

| Feature | Warehouse Management | Automated Fulfillment Centers |

|---|---|---|

| Definition | Manual storage and inventory control system | Automated systems using robotics & software for order fulfillment |

| Efficiency | Moderate, depends on human labor | High, optimized by automation and AI |

| Speed | Slower, manual picking and packing | Faster, robotic picking and sorting |

| Accuracy | Subject to human error | High accuracy through automation |

| Labor Costs | Higher, requires more staff | Lower, reduced human labor |

| Technology Use | Basic software and barcode scanners | Advanced robotics, AI, and IoT |

| Scalability | Limited, relies on manual processes | Highly scalable with modular automation |

| Best For | Small to medium logistics operations | Large-scale, high-volume order fulfillment |

Introduction to Warehouse Management and Automated Fulfillment Centers

Warehouse management involves the coordination of inventory storage, order processing, and logistics to ensure efficient operations within traditional distribution centers. Automated fulfillment centers leverage robotics, AI, and automated systems to enhance speed, accuracy, and scalability in handling e-commerce orders. Both systems optimize supply chain performance, but automated centers significantly reduce labor costs and increase throughput by integrating advanced technology.

Key Differences Between Warehousing and Automated Fulfillment

Warehouse management relies heavily on manual processes for inventory storage, order picking, and shipment preparation, whereas automated fulfillment centers utilize robotics and AI-driven systems to optimize efficiency and accuracy. Warehouses primarily serve as storage facilities with basic inventory control, while automated fulfillment centers integrate advanced automation technologies to facilitate rapid order processing and real-time inventory updates. The key differences lie in operational speed, labor requirements, and technological integration, with automated fulfillment centers offering scalable solutions to meet e-commerce demands.

Core Functions of Traditional Warehouse Management

Traditional warehouse management focuses on inventory control, order picking, and storage optimization, ensuring accurate stock levels and efficient space utilization. It emphasizes manual processes such as receiving shipments, sorting products, and preparing orders for dispatch. Core functions include inventory tracking, labor management, and basic reporting, contrasting with the automated data integration and real-time operations of automated fulfillment centers.

Technology-Driven Operations in Automated Fulfillment Centers

Automated fulfillment centers leverage advanced robotics, AI-driven inventory management, and real-time data analytics to optimize order processing and reduce errors, surpassing traditional warehouse management systems. The integration of conveyor belts, automated storage and retrieval systems (AS/RS), and machine learning algorithms enables faster throughput and enhanced scalability in handling high order volumes. These technology-driven operations drastically improve accuracy, operational efficiency, and labor cost savings compared to manual warehouse environments.

Inventory Accuracy and Control: Manual vs Automated Systems

Warehouse management systems (WMS) rely on manual data entry and human oversight, often leading to errors that impact inventory accuracy and control. Automated fulfillment centers utilize advanced robotics and real-time tracking technologies, significantly reducing discrepancies and improving stock management precision. This automation enhances order fulfillment speed while maintaining higher inventory accuracy compared to traditional warehouse operations.

Order Processing Speed and Efficiency Comparison

Warehouse management systems (WMS) streamline order processing by optimizing inventory tracking and task assignments, significantly reducing picking errors and processing time. Automated fulfillment centers leverage robotics and AI-driven sorting to accelerate order throughput, achieving higher efficiency and faster turnaround times compared to traditional warehouses. Integration of real-time data analytics in both systems enhances decision-making, but automated centers consistently outperform in speed due to mechanized workflows and reduced human intervention.

Labor Requirements and Workforce Implications

Warehouse management relies heavily on manual labor for order picking, inventory control, and shipment preparation, leading to higher workforce demands and labor costs. Automated fulfillment centers utilize robotics and advanced software to reduce human intervention, improving efficiency and lowering labor requirements by up to 60%. This shift necessitates a workforce with technical skills for system maintenance and oversight, changing traditional labor roles toward more specialized positions.

Cost Analysis: Warehousing vs Automated Fulfillment Centers

Warehouse management typically incurs lower upfront capital expenditure compared to automated fulfillment centers, which require significant investment in robotics and technology integration. Operating costs, including labor and maintenance, tend to be higher in traditional warehouses due to manual handling and slower processing times. Automated fulfillment centers offer improved efficiency and scalability that can reduce per-unit costs over time, potentially offsetting the initial financial outlay through faster order fulfillment and reduced error rates.

Scalability and Flexibility for Growing Businesses

Warehouse management systems offer foundational scalability by optimizing inventory tracking and space utilization, but may require significant manual input and upgrades as business demands increase. Automated fulfillment centers provide superior flexibility and rapid scalability through robotics and AI-driven processes, enabling seamless adaptation to fluctuating order volumes and expanding product ranges. Growing businesses benefit from automated solutions that reduce labor costs and enhance throughput, ensuring efficient handling of peak periods and complex fulfillment needs.

Choosing the Right Solution for Your Transportation Needs

Warehouse management systems optimize inventory control, order processing, and shipping logistics, improving efficiency for traditional storage facilities. Automated fulfillment centers integrate robotics and real-time data analytics to expedite picking, packing, and dispatching, enhancing speed and accuracy. Selecting the right solution depends on transportation volume, order complexity, and the need for scalability within supply chain operations.

Related Important Terms

Micro-Fulfillment Centers (MFCs)

Micro-Fulfillment Centers (MFCs) leverage advanced robotics and AI to optimize space and accelerate order processing, contrasting traditional warehouse management systems that prioritize bulk storage and manual handling. This shift enhances urban last-mile delivery efficiency by reducing transit times and operational costs in high-demand areas.

Dark Warehouses

Dark warehouses, also known as automated fulfillment centers, leverage robotics and AI to optimize inventory management and order processing without on-site staff, significantly reducing labor costs and increasing operational efficiency. Warehouse management systems (WMS) integrate with these automated environments to provide real-time data analytics, inventory control, and seamless coordination across decentralized supply chains.

Goods-to-Person (G2P) Systems

Warehouse Management Systems (WMS) optimize inventory control and order processing through software-driven coordination, while Automated Fulfillment Centers utilize Goods-to-Person (G2P) systems that bring items directly to workers, significantly increasing picking speed and accuracy. G2P technology reduces labor costs and minimizes errors by integrating robotics and real-time data analytics, enhancing overall supply chain efficiency in high-volume distribution environments.

Robotic Picking Solutions

Robotic picking solutions in warehouse management enhance accuracy and speed by automating item retrieval, reducing human error, and optimizing inventory flow. Automated fulfillment centers integrate these robotics with advanced software systems for scalable, real-time order processing and streamlined supply chain operations.

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) enhance Warehouse Management by streamlining inventory tracking, order picking, and real-time data integration, leading to increased accuracy and efficiency. In Automated Fulfillment Centers, AMRs enable dynamic routing, faster throughput, and scalable operations by autonomously transporting goods across complex layouts without human intervention.

Put Wall Sorting

Put wall sorting in warehouse management enhances order accuracy by enabling manual item placement into designated slots for efficient batch picking. Automated fulfillment centers use robotic put wall systems to increase throughput, reduce labor costs, and accelerate sorting processes in high-volume distribution environments.

Dynamic Slotting Algorithms

Dynamic slotting algorithms in warehouse management optimize product placement by analyzing demand patterns and replenishment cycles, enhancing picking efficiency and reducing labor costs. Automated fulfillment centers leverage these algorithms to dynamically adjust inventory locations in real-time, increasing throughput and minimizing order fulfillment time.

Digital Twin Warehousing

Digital Twin Warehousing transforms traditional warehouse management by creating real-time virtual replicas of physical facilities, enabling precise monitoring and optimization of inventory flow and equipment usage. Automated Fulfillment Centers leverage these digital twins to enhance decision-making processes, reduce operational costs, and boost order accuracy through predictive analytics and simulation-driven adjustments.

Last-Touch Fulfillment

Warehouse management systems (WMS) primarily focus on inventory tracking, order processing, and labor management within traditional warehouses, while automated fulfillment centers integrate robotics, real-time data analytics, and AI-driven mechanisms to optimize last-touch fulfillment efficiency. Last-touch fulfillment in automated centers significantly reduces order processing time and error rates by streamlining picking, packing, and shipping through advanced automation technologies.

API-Driven Orchestration

API-driven orchestration in warehouse management enables seamless integration of inventory tracking, order processing, and shipment scheduling, enhancing real-time visibility and operational efficiency. Automated fulfillment centers leverage these APIs to coordinate robotics, conveyor systems, and packing stations, optimizing throughput and reducing manual errors in order fulfillment.

Warehouse Management vs Automated Fulfillment Centers Infographic

industrydif.com

industrydif.com