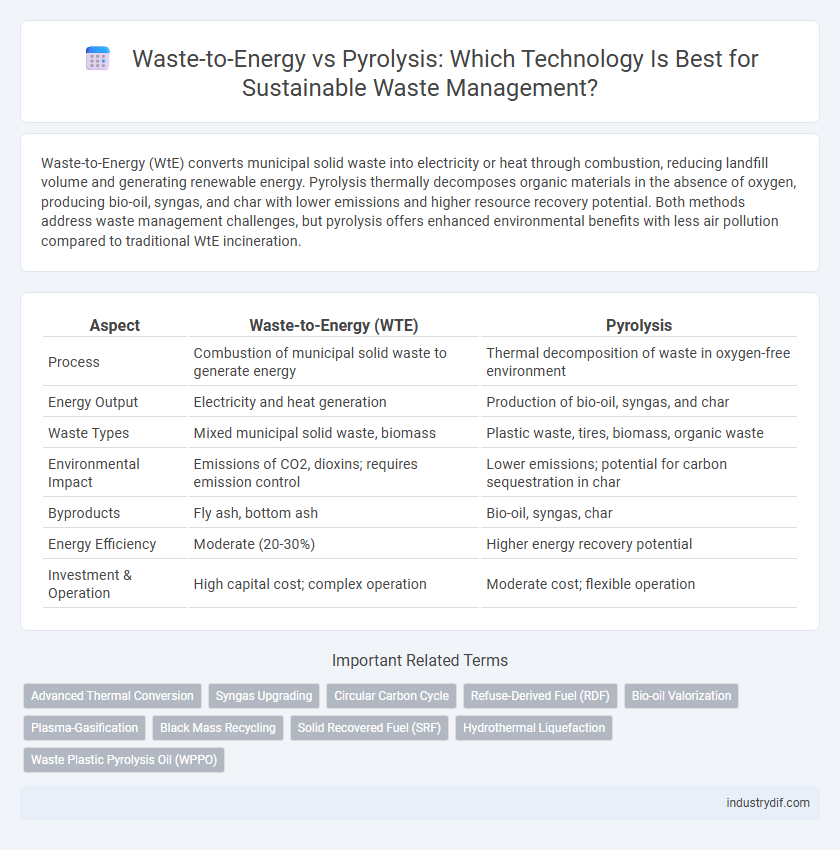

Waste-to-Energy (WtE) converts municipal solid waste into electricity or heat through combustion, reducing landfill volume and generating renewable energy. Pyrolysis thermally decomposes organic materials in the absence of oxygen, producing bio-oil, syngas, and char with lower emissions and higher resource recovery potential. Both methods address waste management challenges, but pyrolysis offers enhanced environmental benefits with less air pollution compared to traditional WtE incineration.

Table of Comparison

| Aspect | Waste-to-Energy (WTE) | Pyrolysis |

|---|---|---|

| Process | Combustion of municipal solid waste to generate energy | Thermal decomposition of waste in oxygen-free environment |

| Energy Output | Electricity and heat generation | Production of bio-oil, syngas, and char |

| Waste Types | Mixed municipal solid waste, biomass | Plastic waste, tires, biomass, organic waste |

| Environmental Impact | Emissions of CO2, dioxins; requires emission control | Lower emissions; potential for carbon sequestration in char |

| Byproducts | Fly ash, bottom ash | Bio-oil, syngas, char |

| Energy Efficiency | Moderate (20-30%) | Higher energy recovery potential |

| Investment & Operation | High capital cost; complex operation | Moderate cost; flexible operation |

Understanding Waste-to-Energy: Definition and Process

Waste-to-energy (WTE) refers to the process of generating energy in the form of electricity or heat from the primary treatment of waste, typically through combustion. This technology reduces the volume of waste sent to landfills while recovering usable energy, often utilizing incinerators with energy recovery systems. WTE contrasts with pyrolysis, which thermally decomposes organic materials in the absence of oxygen, producing synthetic gas, oils, and char rather than direct energy generation.

Pyrolysis Explained: A Modern Waste Solution

Pyrolysis is an advanced thermal decomposition process that converts organic waste into valuable products such as bio-oil, syngas, and char by heating material in an oxygen-free environment. Unlike traditional waste-to-energy incineration, pyrolysis operates at lower temperatures, reducing harmful emissions and enabling the recovery of recyclable materials. This modern waste solution supports sustainable waste management by minimizing landfill use and producing renewable energy resources.

Comparing Technologies: Waste-to-Energy vs Pyrolysis

Waste-to-Energy (WtE) technology converts municipal solid waste into electricity or heat through combustion, achieving energy recovery while reducing landfill volume by up to 90%. Pyrolysis thermally decomposes organic materials in an oxygen-free environment, producing syngas, bio-oil, and char, which can be further refined for fuel or chemical feedstocks, offering higher resource recovery and lower emissions than traditional incineration. Comparing technologies, WtE provides immediate energy output with established infrastructure, whereas pyrolysis offers versatile end-products and improved environmental performance but requires more complex processing and market development for byproducts.

Feedstock Requirements for Each Method

Waste-to-energy (WTE) processes primarily require heterogeneous municipal solid waste (MSW) with a significant calorific value to efficiently generate electricity or heat, while pyrolysis demands feedstock with lower moisture content and higher carbon concentration such as biomass, plastics, and certain industrial wastes for optimal thermal decomposition. WTE systems can handle mixed waste streams but often necessitate preprocessing to remove non-combustibles, whereas pyrolysis benefits from more uniform, sorted feedstock to maximize yield of bio-oil, syngas, and char. The feedstock moisture content, composition, and particle size critically influence reaction efficiency and product quality in both technologies, guiding feedstock selection based on desired outputs and operational conditions.

Energy Output and Efficiency Metrics

Waste-to-energy (WTE) systems typically achieve energy conversion efficiencies between 20% and 30%, with net energy outputs influenced by feedstock composition and combustion technology. Pyrolysis offers higher energy efficiency potential, often reaching 30%-40%, by thermally decomposing organic waste into syngas, bio-oil, and char without oxygen. Metrics such as lower heating value (LHV) of syngas and overall carbon conversion rate are critical in optimizing pyrolysis for sustainable energy recovery compared to conventional WTE processes.

Environmental Impact Assessment

Waste-to-Energy (WTE) facilities typically reduce landfill volume by converting municipal solid waste into electricity or heat through combustion, resulting in lower methane emissions but producing air pollutants such as dioxins and particulate matter requiring stringent emissions controls. Pyrolysis, a thermochemical decomposition process conducted in the absence of oxygen, converts waste into bio-oil, syngas, and char, offering potential for higher energy recovery and lower air pollutants but generating concerns about residual char disposal and potential heavy metal leaching. Environmental Impact Assessments (EIAs) for both technologies emphasize emissions monitoring, residue management, and life cycle greenhouse gas inventories to ensure minimal environmental footprint and compliance with local regulations.

Emissions: Waste-to-Energy vs Pyrolysis

Waste-to-Energy (WtE) plants typically produce higher levels of CO2 and nitrogen oxides due to direct combustion of waste, whereas pyrolysis generates fewer emissions by thermally decomposing organic materials in an oxygen-limited environment. Pyrolysis results in lower particulate matter and dioxin emissions compared to WtE incineration, making it a cleaner alternative for managing municipal solid waste. Emission control technologies like scrubbers and filters are critical in both processes but are more heavily relied upon in WtE facilities to meet environmental regulations.

Market Trends and Adoption Rates

The waste-to-energy market is experiencing steady growth driven by global efforts to reduce landfill dependency and generate renewable energy, with adoption rates peaking in developed regions focused on sustainability. Pyrolysis technology is gaining momentum as a complementary method, particularly in regions targeting plastic waste recycling and carbon emissions reduction, showing faster adoption in emerging economies. Market trends indicate a shift toward integrated waste management solutions combining both technologies to optimize environmental impact and economic returns.

Regulatory Landscape and Compliance

Waste-to-Energy (WTE) facilities operate under strict regulatory frameworks such as the Clean Air Act in the United States, requiring continuous emissions monitoring to ensure compliance with air quality standards. Pyrolysis technology faces evolving regulations, particularly regarding the management of byproducts like char and gases, with increasing emphasis on hazardous waste disposal and air emissions controls. Both methods must align with regional environmental permitting requirements, but pyrolysis often encounters more complex regulatory hurdles due to its relatively newer application and limited standardized guidelines.

Future Prospects: Innovations and Challenges

Waste-to-energy technologies are advancing through innovations like improved gasification and plasma arc processes, which enhance energy recovery efficiency and reduce emissions. Pyrolysis shows future promise by converting diverse waste streams into valuable biofuels and chemicals, yet challenges remain in scaling up systems and managing heterogeneous feedstock. Emerging research in catalyst development and process optimization aims to overcome these barriers, driving sustainable waste management solutions.

Related Important Terms

Advanced Thermal Conversion

Advanced Thermal Conversion technologies such as Waste-to-Energy (WtE) and Pyrolysis transform municipal solid waste into valuable energy sources while minimizing landfill use and emissions. Waste-to-Energy primarily relies on combustion to generate electricity or heat directly, whereas Pyrolysis thermally decomposes waste in an oxygen-free environment to produce syngas, bio-oil, and char, enabling more versatile energy recovery and chemical feedstock applications.

Syngas Upgrading

Syngas upgrading in waste-to-energy processes enhances gas quality by removing impurities like tar, particulates, and acid gases, improving combustion efficiency and reducing emissions. Pyrolysis generates syngas with higher tar content, requiring advanced cleaning and conditioning techniques such as catalytic reforming and scrubbers to optimize energy recovery and ensure environmental compliance.

Circular Carbon Cycle

Waste-to-Energy converts municipal solid waste into electricity through combustion, releasing carbon dioxide that can be captured to support a Circular Carbon Cycle; pyrolysis thermally decomposes organic waste in an oxygen-free environment, producing bio-oil, syngas, and biochar, which can be reused to sequester carbon and enhance soil health. Both processes contribute to reducing landfill dependency while promoting carbon recycling and minimizing greenhouse gas emissions within sustainable waste management frameworks.

Refuse-Derived Fuel (RDF)

Waste-to-Energy (WTE) processes convert Refuse-Derived Fuel (RDF), a recyclable combustible material extracted from municipal solid waste, into electricity or heat through incineration, maximizing energy recovery. Pyrolysis, in contrast, thermally decomposes RDF in an oxygen-free environment to produce syngas, bio-oil, and char, offering a versatile output with lower emissions and enhanced resource recovery.

Bio-oil Valorization

Waste-to-energy processes convert organic waste into energy via combustion, yielding electricity and heat, while pyrolysis thermochemically decomposes biomass under oxygen-free conditions to produce bio-oil, syngas, and char. Bio-oil valorization in pyrolysis focuses on upgrading this liquid product through catalytic hydrotreatment or emulsification, enhancing its fuel quality and chemical feedstock potential compared to the lower-value ash and emissions generated in traditional waste-to-energy systems.

Plasma-Gasification

Plasma-gasification in waste-to-energy processes offers a higher efficiency and lower emission profile compared to traditional pyrolysis by utilizing extremely high temperatures generated through plasma torches to break down waste into syngas and inert slag. This method enables cleaner energy production, reduces the volume of residual waste, and captures hazardous materials more effectively, making it a superior technology for sustainable waste management and renewable energy generation.

Black Mass Recycling

Waste-to-energy (WtE) converts municipal solid waste into electricity and heat through combustion, effectively reducing landfill volume but often struggles with hazardous emissions and limited material recovery. Pyrolysis, a thermal decomposition process operating in an oxygen-free environment, enhances black mass recycling by recovering valuable metals like lithium, cobalt, and nickel from spent lithium-ion batteries, supporting circular economy goals and reducing environmental impact.

Solid Recovered Fuel (SRF)

Waste-to-Energy (WtE) processes convert Solid Recovered Fuel (SRF) into electricity and heat through direct combustion, offering efficient volume reduction and energy recovery from non-recyclable waste. Pyrolysis decomposes SRF in an oxygen-free environment, producing valuable byproducts like synthetic gas, oils, and char, which provide versatile feedstocks for chemical industries and reduce landfill dependency.

Hydrothermal Liquefaction

Hydrothermal Liquefaction (HTL) converts wet biomass and organic waste into bio-crude oil under high temperature and pressure, offering higher energy recovery compared to traditional Waste-to-Energy incineration and Pyrolysis processes. HTL operates in a water-rich environment, reducing the need for pre-drying and enabling efficient conversion of sewage sludge and food waste into valuable liquid fuels.

Waste Plastic Pyrolysis Oil (WPPO)

Waste plastic pyrolysis oil (WPPO) offers a sustainable alternative in waste management by converting plastic waste into valuable fuel through thermal decomposition, producing energy-rich oil suitable for industrial applications. Unlike conventional waste-to-energy incineration, pyrolysis minimizes harmful emissions and recovers higher energy content from plastic waste, making WPPO a cleaner and more efficient resource for reducing landfill dependency.

Waste-to-Energy vs Pyrolysis Infographic

industrydif.com

industrydif.com