Municipal solid waste management primarily involves the collection, transportation, and disposal of everyday household and commercial refuse, focusing on reducing landfill use and promoting recycling. E-waste mining targets the extraction of valuable metals and rare earth elements from discarded electronic devices, providing a sustainable alternative to traditional mining. Both approaches are crucial for minimizing environmental impact, conserving natural resources, and promoting circular economy principles in waste management.

Table of Comparison

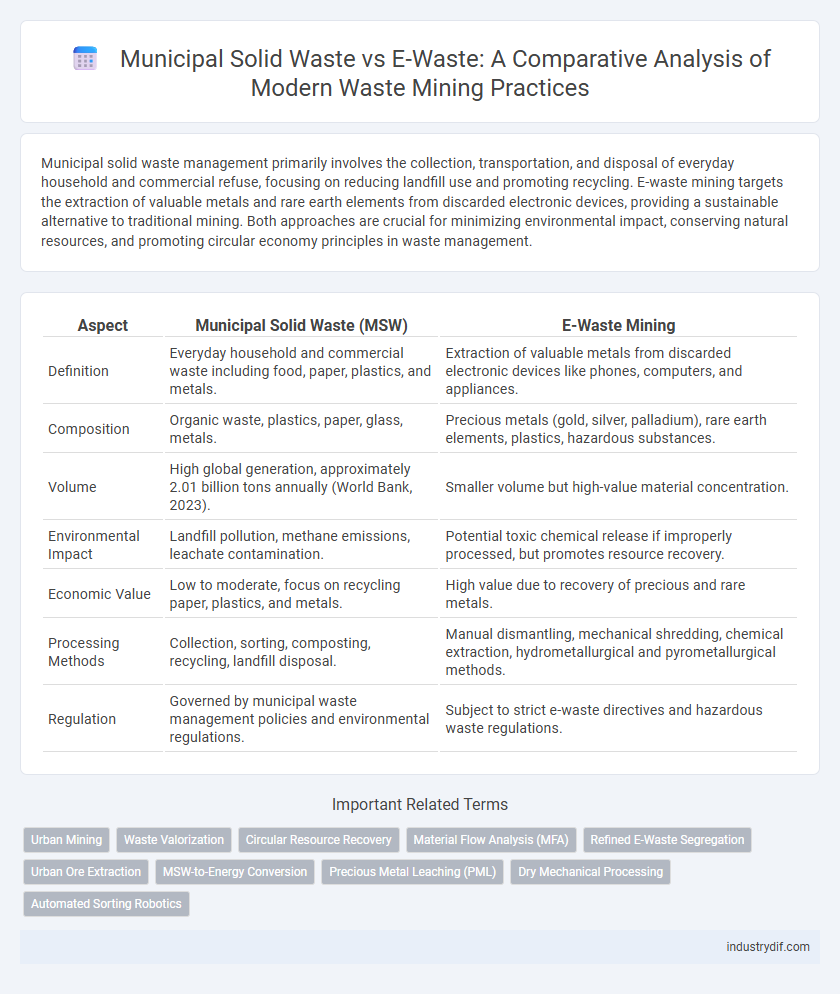

| Aspect | Municipal Solid Waste (MSW) | E-Waste Mining |

|---|---|---|

| Definition | Everyday household and commercial waste including food, paper, plastics, and metals. | Extraction of valuable metals from discarded electronic devices like phones, computers, and appliances. |

| Composition | Organic waste, plastics, paper, glass, metals. | Precious metals (gold, silver, palladium), rare earth elements, plastics, hazardous substances. |

| Volume | High global generation, approximately 2.01 billion tons annually (World Bank, 2023). | Smaller volume but high-value material concentration. |

| Environmental Impact | Landfill pollution, methane emissions, leachate contamination. | Potential toxic chemical release if improperly processed, but promotes resource recovery. |

| Economic Value | Low to moderate, focus on recycling paper, plastics, and metals. | High value due to recovery of precious and rare metals. |

| Processing Methods | Collection, sorting, composting, recycling, landfill disposal. | Manual dismantling, mechanical shredding, chemical extraction, hydrometallurgical and pyrometallurgical methods. |

| Regulation | Governed by municipal waste management policies and environmental regulations. | Subject to strict e-waste directives and hazardous waste regulations. |

Definition and Composition of Municipal Solid Waste

Municipal Solid Waste (MSW) consists of everyday items discarded by the public, including organic waste, paper, plastics, metals, and glass, generated from households, commercial establishments, and institutions. The composition of MSW varies widely depending on urbanization levels, consumption patterns, and local waste management practices, typically dominated by biodegradable materials and recyclables. Unlike E-Waste, which specifically refers to discarded electronic devices containing hazardous components and valuable metals, MSW encompasses a broader range of non-hazardous refuse requiring diverse treatment and disposal methods.

Understanding E-Waste Mining: Scope and Processes

E-waste mining involves the extraction of valuable metals such as gold, silver, and palladium from discarded electronic devices, differing from municipal solid waste management that primarily focuses on general household refuse. This process utilizes advanced technologies like hydrometallurgy and bioleaching to recover precious materials while reducing environmental impact. Understanding the scope of e-waste mining is critical for promoting sustainable resource recovery and minimizing the toxic effects associated with electronic waste disposal.

Key Differences Between MSW and E-Waste Streams

Municipal Solid Waste (MSW) primarily consists of everyday household materials such as food scraps, paper, plastics, and glass, while E-Waste streams include discarded electronic devices like smartphones, computers, and televisions containing valuable metals like gold, silver, and copper. The recycling processes differ significantly; MSW focuses on organic decomposition and conventional material recovery, whereas E-Waste mining emphasizes extraction of precious and rare earth metals through specialized techniques. Environmental impacts vary as well, with E-Waste posing higher risks due to toxic components like lead and mercury, necessitating distinct handling and regulatory frameworks compared to general MSW.

Environmental Impacts of Municipal Solid Waste Disposal

Municipal solid waste disposal generates significant environmental impacts including greenhouse gas emissions, groundwater contamination, and soil degradation due to landfill leachate and methane release. Improper management of MSW leads to toxic pollutants entering ecosystems, affecting biodiversity and human health. In contrast, e-waste mining, which recovers valuable metals from electronic waste, reduces the volume of hazardous substances released but presents its own environmental challenges related to processing and chemical waste.

Toxicity and Hazards Associated with E-Waste

E-waste contains hazardous substances such as lead, mercury, cadmium, and brominated flame retardants, posing significant toxicity risks compared to municipal solid waste. Improper handling and disposal of e-waste can lead to severe environmental pollution and adverse health effects, including neurological damage and respiratory problems. Contrarily, municipal solid waste primarily comprises organic material and inert waste, presenting lower toxicity and hazard levels in comparison.

Collection and Segregation Methods for MSW vs E-Waste

Municipal solid waste (MSW) collection relies on curbside pickup, centralized drop-off sites, and community bins, with segregation typically occurring at source through color-coded containers separating organic, recyclable, and non-recyclable materials. E-waste mining involves specialized collection points and reverse logistics systems to handle hazardous components and valuable metals; segregation methods emphasize manual disassembly and automated separation to isolate metals, plastics, and glass for efficient resource recovery. Effective segregation in MSW focuses on volume reduction and contamination control, whereas e-waste collection prioritizes safe handling of toxic substances and maximization of precious metal extraction.

Resource Recovery and Recycling Rates Comparison

Municipal solid waste (MSW) primarily consists of everyday household items, with recycling rates averaging around 35%, while e-waste mining targets valuable metals such as gold, silver, and copper, achieving higher resource recovery efficiencies of up to 70%. Advances in e-waste recycling technologies enhance metal extraction processes, reducing environmental pollution and supplying critical materials for electronics manufacturing. Enhanced sorting and processing methods in MSW streams can improve recycling rates, but the heterogeneous nature of e-waste allows for more concentrated recovery of rare and precious metals.

Technological Innovations in E-Waste Mining

Technological innovations in e-waste mining have revolutionized the recovery of valuable metals such as gold, silver, and palladium from discarded electronics, enhancing resource efficiency compared to conventional municipal solid waste management. Advanced techniques like bioleaching and automated robotic sorting enable higher precision extraction while reducing environmental impact. These innovations contribute significantly to sustainable waste management by promoting circular economy practices and minimizing the depletion of natural mineral reserves.

Policy and Regulatory Frameworks for Waste Management

Municipal solid waste management policies emphasize source segregation, recycling mandates, and landfill regulations to minimize environmental impact and promote sustainable urban waste handling. E-waste mining regulations focus on establishing safe dismantling procedures, reducing hazardous material exposure, and incentivizing the recovery of valuable metals through extended producer responsibility (EPR) schemes. Effective frameworks integrate strict compliance monitoring, public-private partnerships, and financial incentives to enhance resource recovery and reduce landfill dependency in both sectors.

Future Trends: Integrating E-Waste Mining into MSW Systems

Future trends in waste management emphasize integrating e-waste mining into municipal solid waste (MSW) systems to enhance resource recovery and reduce landfill dependency. Advanced sorting technologies and automated recycling facilities enable efficient extraction of valuable metals like gold, copper, and rare earth elements from e-waste within MSW streams. This integrated approach supports circular economy goals by promoting sustainable material flow and minimizing environmental impact.

Related Important Terms

Urban Mining

Urban mining leverages the extraction of valuable metals and materials from Municipal Solid Waste (MSW) and Electronic Waste (E-Waste), significantly reducing environmental impact while recovering scarce resources like gold, silver, and rare earth elements. Advanced urban mining techniques enhance sustainable waste management by transforming discarded electronics and household waste into high-purity raw materials for manufacturing and industrial reuse.

Waste Valorization

Municipal solid waste (MSW) valorization involves converting everyday household waste into valuable resources through processes such as composting, recycling, and energy recovery, thereby reducing landfill dependency and environmental pollution. E-waste mining focuses on extracting precious metals like gold, silver, and palladium from discarded electronic devices, enhancing resource efficiency and contributing to sustainable material circulation within the circular economy.

Circular Resource Recovery

Municipal solid waste (MSW) primarily includes everyday household and commercial refuse rich in organic materials, plastics, and metals, whereas e-waste mining targets discarded electronic devices containing valuable metals like gold, silver, and rare earth elements. Circular resource recovery from MSW emphasizes composting organic fractions and recycling plastics and metals, while e-waste mining enhances metal reclamation through advanced extraction techniques, driving sustainable material reuse and reducing environmental pollution.

Material Flow Analysis (MFA)

Material Flow Analysis (MFA) reveals distinct pathways in Municipal Solid Waste (MSW) and E-Waste Mining, with MSW primarily comprising organic and inorganic household refuse, while E-Waste focuses on recovering valuable metals like gold, copper, and rare earth elements through targeted extraction processes. MFA enables precise quantification of resource flows and environmental impacts, optimizing recycling rates and minimizing landfill reliance for both waste streams.

Refined E-Waste Segregation

Refined e-waste segregation involves advanced sorting techniques to separate valuable metals like gold, silver, and copper from hazardous components, enhancing material recovery compared to traditional municipal solid waste processing. This targeted approach reduces environmental contamination and supports sustainable resource extraction by optimizing the recycling of electronic components.

Urban Ore Extraction

Urban ore extraction from municipal solid waste (MSW) targets valuable materials like metals and rare earth elements embedded in e-waste components, significantly reducing landfill volume while recovering resources. Advanced sorting and processing technologies enable efficient separation of electronic waste from general MSW, supporting sustainable resource management and circular economy goals.

MSW-to-Energy Conversion

Municipal Solid Waste (MSW) to energy conversion involves processing urban waste to generate electricity or heat through incineration, anaerobic digestion, or gasification, significantly reducing landfill volume while recovering valuable energy. Unlike E-Waste mining that targets precious metals recovery from electronic components, MSW-to-energy focuses on sustainable waste management by transforming organic and non-recyclable waste materials into renewable energy sources.

Precious Metal Leaching (PML)

Municipal solid waste (MSW) leaches precious metals at significantly lower concentrations compared to e-waste mining, which yields high-value metals such as gold, silver, and palladium through targeted precious metal leaching (PML) processes. Efficient PML techniques in e-waste recycling enhance metal recovery rates and reduce environmental contamination risks associated with conventional MSW disposal methods.

Dry Mechanical Processing

Dry Mechanical Processing in municipal solid waste efficiently separates recyclable materials through shredding, screening, and magnetic sorting, reducing landfill volume and recovering valuable metals. E-waste mining employs advanced dry mechanical techniques to extract precious metals like gold, silver, and copper without chemical treatments, promoting sustainable recycling and resource conservation.

Automated Sorting Robotics

Automated sorting robotics significantly enhance the efficiency of municipal solid waste (MSW) management by rapidly identifying and separating recyclable materials, thereby reducing landfill volumes and environmental impact. In e-waste mining, these systems utilize advanced sensors and AI algorithms to extract valuable metals such as gold, silver, and rare earth elements, optimizing resource recovery and minimizing hazardous waste exposure.

Municipal Solid Waste vs E-Waste Mining Infographic

industrydif.com

industrydif.com