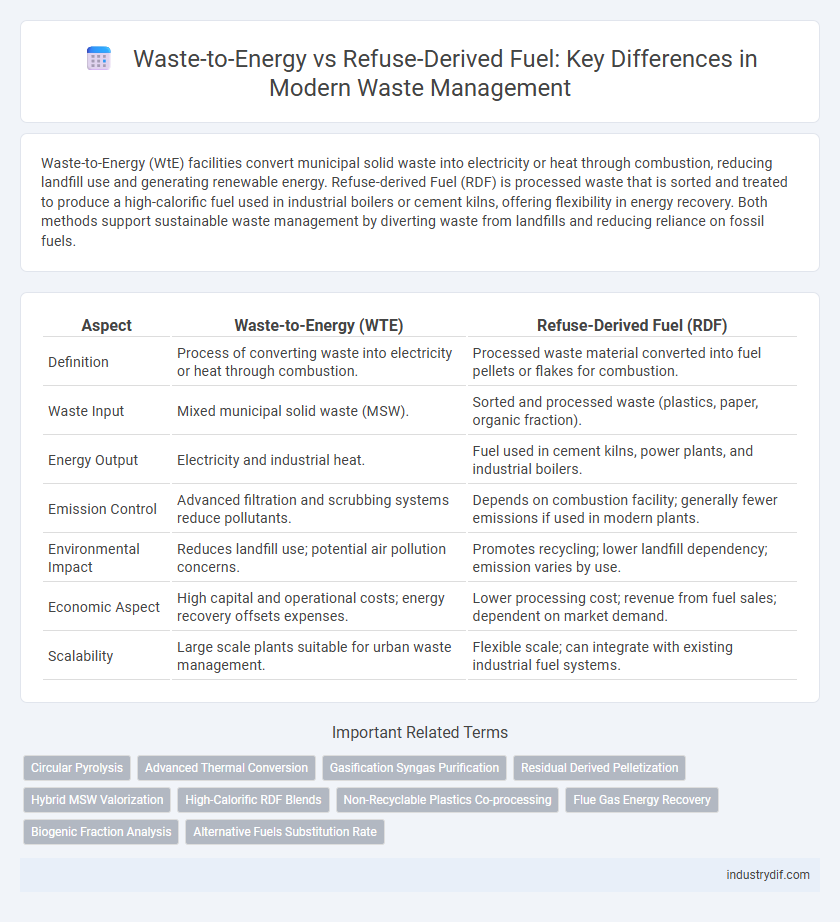

Waste-to-Energy (WtE) facilities convert municipal solid waste into electricity or heat through combustion, reducing landfill use and generating renewable energy. Refuse-derived Fuel (RDF) is processed waste that is sorted and treated to produce a high-calorific fuel used in industrial boilers or cement kilns, offering flexibility in energy recovery. Both methods support sustainable waste management by diverting waste from landfills and reducing reliance on fossil fuels.

Table of Comparison

| Aspect | Waste-to-Energy (WTE) | Refuse-Derived Fuel (RDF) |

|---|---|---|

| Definition | Process of converting waste into electricity or heat through combustion. | Processed waste material converted into fuel pellets or flakes for combustion. |

| Waste Input | Mixed municipal solid waste (MSW). | Sorted and processed waste (plastics, paper, organic fraction). |

| Energy Output | Electricity and industrial heat. | Fuel used in cement kilns, power plants, and industrial boilers. |

| Emission Control | Advanced filtration and scrubbing systems reduce pollutants. | Depends on combustion facility; generally fewer emissions if used in modern plants. |

| Environmental Impact | Reduces landfill use; potential air pollution concerns. | Promotes recycling; lower landfill dependency; emission varies by use. |

| Economic Aspect | High capital and operational costs; energy recovery offsets expenses. | Lower processing cost; revenue from fuel sales; dependent on market demand. |

| Scalability | Large scale plants suitable for urban waste management. | Flexible scale; can integrate with existing industrial fuel systems. |

Introduction to Waste-to-Energy and Refuse-derived Fuel

Waste-to-Energy (WtE) converts municipal solid waste into electricity or heat through combustion, reducing landfill volume and recovering energy. Refuse-derived Fuel (RDF) involves processing waste materials into combustible fuel pellets or flakes, enhancing fuel quality and handling for industrial uses. Both technologies play critical roles in sustainable waste management by transforming waste into valuable energy resources while minimizing environmental impact.

Waste Stream Characterization and Composition

Waste-to-Energy (WTE) facilities primarily process mixed municipal solid waste with a heterogeneous composition, including organic materials, plastics, and paper, necessitating comprehensive waste stream characterization to optimize combustion efficiency. Refuse-derived Fuel (RDF) production involves the segregation and preprocessing of waste streams to concentrate combustible components such as plastics, textiles, and non-recyclable paper, improving fuel consistency and calorific value. Detailed analysis of waste composition, moisture content, and contaminants is critical to enhance energy recovery and minimize emissions in both WTE and RDF processes.

Technology Overview: Waste-to-Energy Processes

Waste-to-Energy (WtE) processes primarily convert municipal solid waste into electricity and heat using thermal technologies such as incineration, gasification, and pyrolysis. Refuse-derived fuel (RDF) is produced by processing mixed waste to extract combustible materials, which are then used as a fuel source in cement kilns, power plants, or industrial boilers. WtE systems emphasize energy recovery through direct thermal conversion, while RDF focuses on creating a standardized fuel that supports existing combustion technologies.

Refuse-derived Fuel Production Methods

Refuse-derived fuel (RDF) production involves sorting, shredding, and drying municipal solid waste to extract combustible materials such as plastics, paper, and textiles, optimizing fuel quality and energy content. Advanced sorting technologies like magnetic separation, air classification, and optical sorting enhance RDF purity by removing metals and inert materials. This process significantly improves combustion efficiency and emissions control compared to direct waste-to-energy incineration, making RDF a valuable feedstock for co-firing in cement kilns and power plants.

Energy Output Comparison: Efficiency and Yield

Waste-to-Energy (WtE) systems typically achieve higher energy output efficiency by directly converting municipal solid waste into electricity or heat through combustion, with efficiency rates ranging from 20% to 28%. Refuse-derived Fuel (RDF) involves processing waste into a fuel substitute for coal, yielding a lower net energy output but providing flexibility in industrial applications. WtE offers superior overall energy yield per ton of waste, making it a more effective solution for maximizing energy recovery.

Environmental Impacts and Emissions

Waste-to-Energy (WtE) processes typically involve incineration, generating electricity while reducing landfill volume but emitting pollutants such as dioxins, particulate matter, and greenhouse gases. Refuse-derived Fuel (RDF) is produced by processing municipal solid waste into a fuel form that can be burned in industrial boilers or cement kilns, often resulting in lower emissions of heavy metals and toxic compounds compared to direct incineration. Both methods reduce landfill dependency, yet RDF generally offers a more controlled combustion environment with optimized emissions profiles, contributing to improved air quality and lower environmental impact.

Regulatory Frameworks and Standards

Waste-to-Energy (WTE) facilities are governed by stringent regulatory frameworks such as the U.S. Environmental Protection Agency's Clean Air Act and the European Union's Waste Framework Directive, which set emission limits and require advanced pollution control technologies to ensure environmental compliance. Refuse-derived Fuel (RDF) production and use adhere to standards like ISO 18655 for solid recovered fuels and various regional waste management policies that dictate quality specifications, combustion efficiency, and ash residue limits to promote sustainable energy recovery. Regulatory distinctions emphasize WTE's comprehensive incineration process under strict emission controls, while RDF regulations focus on fuel quality and its integration into existing energy systems, ensuring both methods meet evolving environmental protection and waste reduction goals.

Economic Considerations and Cost-effectiveness

Waste-to-energy (WTE) facilities generally require higher initial capital investment but offer lower operating costs through direct energy generation, providing a more stable revenue stream compared to refuse-derived fuel (RDF) production. RDF systems involve additional processing costs to convert waste into fuel pellets, but they benefit from flexibility in market demand and lower upfront expenditure, enhancing short-term financial feasibility. Economic viability for both technologies depends on local energy prices, tipping fees, and regulatory incentives that impact long-term cost-effectiveness and return on investment.

Market Applications and Industry Adoption

Waste-to-Energy (WtE) technologies primarily serve municipal solid waste management through thermal processes such as incineration and gasification, widely adopted by urban centers aiming to reduce landfill dependency while generating electricity or heat. Refuse-derived Fuel (RDF) is predominantly utilized in cement kilns, industrial boilers, and power plants, where customized fuel blends optimize combustion and lower fossil fuel use, appealing to industries seeking sustainable energy alternatives. Market adoption trends indicate WtE facilities are expanding in densely populated regions due to regulatory pressure on waste diversion, whereas RDF markets grow in sectors prioritizing cost-effective, low-emission fuel substitutes.

Future Trends and Technological Innovations in Waste Valorization

Future trends in waste valorization emphasize advanced Waste-to-Energy (WtE) technologies incorporating plasma gasification and high-efficiency combined heat and power (CHP) systems, significantly enhancing energy recovery from municipal solid waste. Refuse-derived fuel (RDF) innovations focus on improving feedstock preprocessing through AI-driven sorting and upgraded pelletization techniques, boosting fuel consistency and calorific value. Emerging hybrid systems integrating WtE and RDF demonstrate potential for optimized resource recovery, lower emissions, and circular economy support in urban waste management.

Related Important Terms

Circular Pyrolysis

Circular pyrolysis offers a sustainable alternative by converting waste into high-energy refuse-derived fuel (RDF), enhancing the efficiency of waste-to-energy processes through thermal decomposition of organic materials without combustion. This method reduces landfill use and greenhouse gas emissions while generating renewable energy, positioning circular pyrolysis as a key technology in advancing circular economy goals within waste management.

Advanced Thermal Conversion

Advanced thermal conversion technologies enable Waste-to-Energy plants to efficiently generate electricity by combusting municipal solid waste, achieving higher energy recovery rates compared to Refuse-derived Fuel systems that preprocess waste into combustible pellets for industrial use; these methods reduce landfill dependency while optimizing carbon emissions control and resource recovery. Integrating gasification or pyrolysis within Waste-to-Energy facilities enhances thermal efficiency and syngas production, whereas Refuse-derived Fuel emphasizes consistent fuel quality and versatility for cement kilns and power plants, highlighting distinct operational and environmental advantages in waste management strategies.

Gasification Syngas Purification

Gasification syngas purification in Waste-to-Energy systems enhances energy recovery by converting municipal solid waste into a cleaner, combustible gas, reducing tar and particulate contaminants for efficient combustion. Refuse-derived fuel processes require advanced syngas cleaning technologies to optimize energy output and minimize emissions, promoting sustainable waste management and power generation.

Residual Derived Pelletization

Residual derived pelletization in refuse-derived fuel (RDF) enhances waste-to-energy (WTE) systems by transforming heterogeneous waste into uniform, energy-dense pellets that improve combustion efficiency and reduce emissions. This pelletized RDF serves as a reliable alternative fuel in WTE plants, optimizing thermal output and lowering landfill dependency compared to conventional waste processing methods.

Hybrid MSW Valorization

Hybrid MSW valorization combines Waste-to-Energy (WtE) technologies and Refuse-Derived Fuel (RDF) production to maximize energy recovery from municipal solid waste. This integrated approach enhances sustainability by reducing landfill volumes, improving combustion efficiency, and generating higher-value fuels for industrial applications.

High-Calorific RDF Blends

High-Calorific Refuse-derived Fuel (RDF) blends offer superior energy efficiency compared to traditional Waste-to-Energy (WtE) methods by optimizing the calorific value through selective sorting and preprocessing of municipal solid waste. These blends reduce emissions and operational costs by providing a consistent, high-energy fuel source that enhances combustion stability in thermal power plants.

Non-Recyclable Plastics Co-processing

Waste-to-energy (WTE) systems convert non-recyclable plastics into energy through direct combustion, generating electricity and reducing landfill volume with lower greenhouse gas emissions compared to traditional incineration. Refuse-derived fuel (RDF) processes non-recyclable plastics by shredding and pelletizing waste materials, improving fuel consistency and efficiency for industrial co-processing in cement kilns and power plants, enhancing resource recovery while minimizing environmental impact.

Flue Gas Energy Recovery

Flue gas energy recovery in Waste-to-Energy (WtE) plants captures heat from combustion gases, improving overall efficiency by generating steam or electricity, while Refuse-derived Fuel (RDF) systems primarily process waste into fuel for external combustion, offering less direct flue gas energy recovery. WtE technologies typically achieve higher energy conversion rates and better emissions control through advanced flue gas treatment systems compared to RDF applications.

Biogenic Fraction Analysis

Waste-to-Energy (WtE) plants primarily utilize the biogenic fraction of waste, which is crucial for reducing carbon emissions through renewable energy production, whereas Refuse-derived Fuel (RDF) often contains a variable biogenic content affecting its combustion efficiency and environmental impact. Accurate biogenic fraction analysis using methods such as radiocarbon (C-14) dating or proximate analysis enhances the optimization of both WtE and RDF processes by ensuring compliance with renewable energy policies and improving lifecycle carbon accounting.

Alternative Fuels Substitution Rate

Waste-to-Energy facilities typically achieve higher Alternative Fuels Substitution Rates by converting diverse municipal solid waste into electricity and heat, whereas Refuse-derived Fuel processes consist of mechanically sorting and compressing waste into standardized fuel pellets primarily used in industrial burners. The substitution rate in Waste-to-Energy plants can exceed 50%, significantly displacing fossil fuels, while Refuse-derived Fuel often attains substitution rates around 30-40%, depending on fuel quality and industrial application.

Waste-to-Energy vs Refuse-derived Fuel Infographic

industrydif.com

industrydif.com