Chlorination effectively kills bacteria and viruses by releasing chlorine that disrupts microbial cell membranes, offering residual protection in water distribution systems. UV-C disinfection inactivates pathogens by damaging their DNA, providing chemical-free treatment without altering water taste or odor. Both methods ensure safe drinking water, but UV-C requires clear water and lacks residual disinfectant properties, whereas chlorination continues to protect water downstream.

Table of Comparison

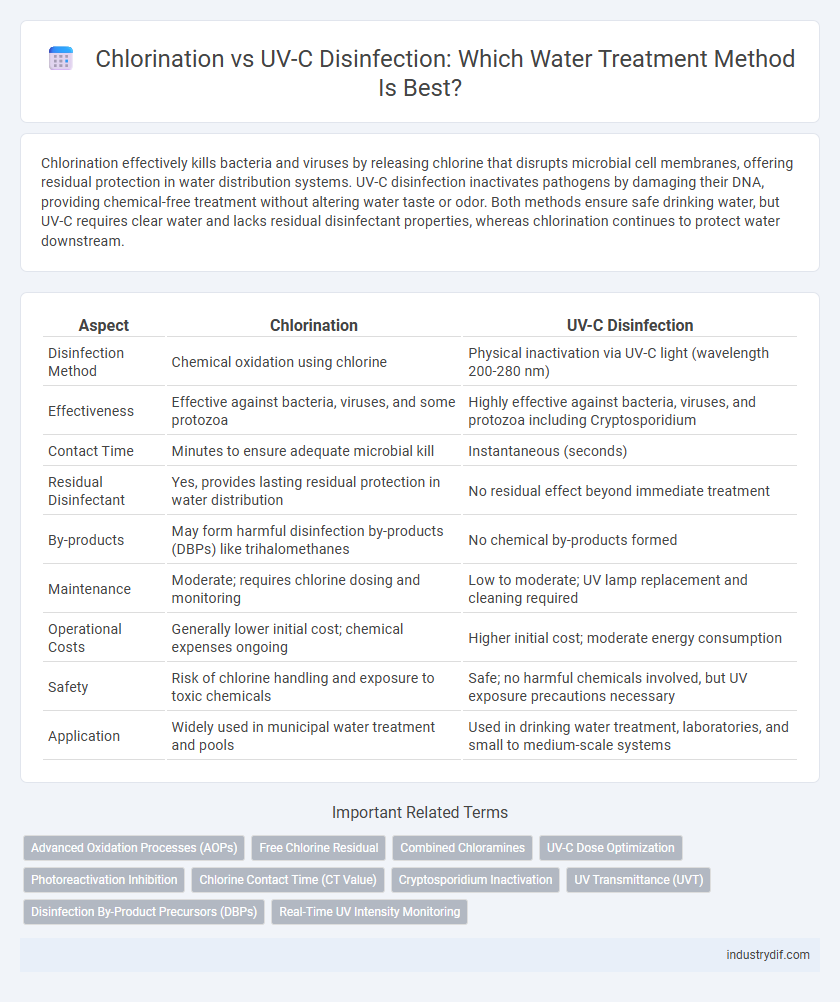

| Aspect | Chlorination | UV-C Disinfection |

|---|---|---|

| Disinfection Method | Chemical oxidation using chlorine | Physical inactivation via UV-C light (wavelength 200-280 nm) |

| Effectiveness | Effective against bacteria, viruses, and some protozoa | Highly effective against bacteria, viruses, and protozoa including Cryptosporidium |

| Contact Time | Minutes to ensure adequate microbial kill | Instantaneous (seconds) |

| Residual Disinfectant | Yes, provides lasting residual protection in water distribution | No residual effect beyond immediate treatment |

| By-products | May form harmful disinfection by-products (DBPs) like trihalomethanes | No chemical by-products formed |

| Maintenance | Moderate; requires chlorine dosing and monitoring | Low to moderate; UV lamp replacement and cleaning required |

| Operational Costs | Generally lower initial cost; chemical expenses ongoing | Higher initial cost; moderate energy consumption |

| Safety | Risk of chlorine handling and exposure to toxic chemicals | Safe; no harmful chemicals involved, but UV exposure precautions necessary |

| Application | Widely used in municipal water treatment and pools | Used in drinking water treatment, laboratories, and small to medium-scale systems |

Introduction to Water Disinfection Methods

Chlorination remains a widely used water disinfection method due to its effectiveness against bacteria and viruses and its ability to provide residual protection in distribution systems. UV-C disinfection uses ultraviolet light to inactivate microorganisms without adding chemicals, making it suitable for improving water quality without altering taste or odor. Both methods play crucial roles in ensuring safe drinking water, with chlorination favored for long-term residual effects and UV-C preferred for chemical-free microbial control.

Understanding Chlorination in Water Treatment

Chlorination in water treatment involves adding chlorine or chlorine compounds to disinfect water by killing harmful pathogens and bacteria. This method is effective for maintaining residual disinfectant levels in the distribution system, preventing microbial regrowth. While chlorination ensures long-lasting water safety, careful control is necessary to minimize the formation of harmful disinfection by-products such as trihalomethanes (THMs).

The Science Behind UV-C Disinfection

UV-C disinfection uses ultraviolet light at a wavelength of 200-280 nanometers to damage the DNA and RNA of microorganisms, effectively inactivating bacteria, viruses, and protozoa in water. This method disrupts microbial replication without introducing chemicals, avoiding harmful byproducts commonly associated with chlorination. UV-C disinfection offers rapid treatment and maintains water taste and odor while ensuring pathogen control through precise photochemical reactions.

Efficacy of Chlorination vs UV-C Against Pathogens

Chlorination effectively inactivates a wide range of pathogens including bacteria, viruses, and protozoa by disrupting microbial cell membranes and denaturing proteins, making it a preferred choice for continuous water disinfection. UV-C disinfection targets pathogens by damaging their DNA and RNA, preventing replication, with proven high efficacy against chlorine-resistant organisms like Cryptosporidium and Giardia. While chlorination provides residual protection in distribution systems, UV-C requires proper exposure and maintenance but excels in rapid pathogen inactivation without producing harmful disinfection byproducts.

Operational Costs and Maintenance Considerations

Chlorination systems generally have lower upfront costs but incur higher ongoing expenses due to chemical procurement, storage, and handling requirements. UV-C disinfection demands higher initial investment for lamps and equipment but offers reduced operational costs as it minimizes chemical use and waste disposal. Maintenance for chlorination involves regular chemical checks and equipment cleaning, whereas UV-C systems require periodic lamp replacement and reactor cleaning to ensure consistent disinfection efficacy.

Environmental Impact of Chlorination and UV-C

Chlorination releases harmful byproducts such as trihalomethanes and haloacetic acids into water, posing risks to aquatic ecosystems and human health. UV-C disinfection eliminates pathogens without chemical residues, minimizing environmental pollution and toxic waste generation. Energy consumption is higher with UV-C systems but yields a cleaner, eco-friendlier alternative to chemical disinfectants.

Safety and Health Implications

Chlorination effectively eliminates pathogens but can form harmful disinfection byproducts like trihalomethanes, posing long-term health risks. UV-C disinfection provides a chemical-free alternative that inactivates microorganisms without generating toxic residues, enhancing water safety. However, UV-C systems require proper maintenance to ensure consistent exposure and avoid microbial survival.

Regulatory Standards and Compliance

Chlorination complies with EPA regulations and WHO guidelines, requiring monitored residual chlorine levels to ensure continuous disinfection and prevent microbial regrowth in water systems. UV-C disinfection meets standards set by NSF/ANSI 55 for ultraviolet microbiological water treatment, emphasizing dosage and exposure time for pathogen inactivation without chemical residues. Both methods must adhere to local regulatory frameworks, balancing efficacy, safety, and environmental impact in water treatment processes.

Applications in Municipal and Industrial Water

Chlorination effectively eliminates a wide range of pathogens in municipal water treatment, providing residual disinfection that prevents microbial regrowth throughout distribution systems. UV-C disinfection offers chemical-free inactivation of microorganisms, making it ideal for industrial water applications where sensitive processes require minimal chemical interference. Municipal systems benefit from chlorination's lasting protection, while industries prioritize UV-C for its rapid, environmentally friendly pathogen control without producing harmful byproducts.

Future Trends in Water Disinfection Technologies

Emerging trends in water disinfection increasingly favor hybrid systems combining chlorination and UV-C technology to maximize pathogen inactivation while minimizing chemical byproducts and energy consumption. Advances in UV-C LED technology promise greater efficiency and compact system design, enabling widespread adoption in residential and industrial settings. Integrating real-time water quality sensors with automated controls enhances disinfection precision, reducing operational costs and environmental impacts.

Related Important Terms

Advanced Oxidation Processes (AOPs)

Advanced Oxidation Processes (AOPs) enhance water treatment by combining UV-C disinfection with chemical oxidants, generating highly reactive hydroxyl radicals that effectively degrade organic contaminants and pathogens beyond the capabilities of chlorination alone. This method offers superior elimination of micropollutants and reduces disinfection byproducts compared to traditional chlorination, making AOPs a cutting-edge solution for water purification.

Free Chlorine Residual

Free chlorine residual acts as a critical indicator of ongoing disinfection efficacy in chlorination systems, sustaining antimicrobial activity in water distribution networks. UV-C disinfection, while effective for pathogen inactivation at the point of treatment, does not provide a residual effect, making free chlorine residual essential for preventing microbial regrowth during water storage and transit.

Combined Chloramines

Combined chloramines, formed by the reaction of chlorine with ammonia in water, provide a longer-lasting disinfectant residual compared to UV-C disinfection, which inactivates pathogens quickly but leaves no residual effect. While UV-C does not produce chloramine byproducts, chloramination helps control microbial regrowth in distribution systems despite concerns over taste, odor, and potential formation of disinfection byproducts.

UV-C Dose Optimization

UV-C disinfection effectiveness depends on precise UV-C dose optimization, which ensures adequate microbial inactivation while minimizing energy consumption and preventing water quality degradation. Chlorination relies on chemical reactions for pathogen removal, whereas UV-C systems require calibrated irradiance levels to achieve target log reductions of contaminants without forming harmful disinfection byproducts.

Photoreactivation Inhibition

Chlorination effectively prevents photoreactivation by causing irreversible damage to microbial DNA, ensuring prolonged disinfection efficacy. UV-C disinfection, while highly effective at inactivating pathogens through DNA damage, is susceptible to photoreactivation, which can restore microorganism viability when exposed to visible light post-treatment.

Chlorine Contact Time (CT Value)

Chlorine Contact Time (CT value) is critical in chlorination, representing the product of disinfectant concentration and exposure time required to achieve effective pathogen inactivation. UV-C disinfection relies on UV dose rather than CT value, making chlorination's CT a key metric for validating microbial safety in water treatment.

Cryptosporidium Inactivation

Chlorination is less effective against Cryptosporidium oocysts due to their resistant outer shell, while UV-C disinfection inactivates these pathogens by damaging their DNA, preventing replication and infection. UV-C systems provide a reliable method for Cryptosporidium control in water treatment, often preferred in scenarios requiring high-level pathogen inactivation without chemical byproducts.

UV Transmittance (UVT)

UV transmittance (UVT) plays a critical role in the efficacy of UV-C disinfection, as higher UVT values indicate clearer water that allows deeper penetration of UV light to inactivate pathogens effectively. Unlike chlorination, which relies on chemical reactions, UV-C disinfection efficiency directly depends on UVT levels, making water clarity essential for optimal microbial inactivation without chemical byproducts.

Disinfection By-Product Precursors (DBPs)

Chlorination in water treatment often leads to the formation of disinfection by-product precursors (DBPs), such as trihalomethanes and haloacetic acids, which pose health risks. UV-C disinfection effectively inactivates pathogens without creating DBPs, offering a safer alternative for water purification.

Real-Time UV Intensity Monitoring

Real-time UV intensity monitoring enhances UV-C disinfection by ensuring consistent and effective inactivation of pathogens in water treatment, outperforming chlorination which relies on chemical dosing that can fluctuate. This technology reduces the risk of under- or over-treatment, minimizing harmful disinfection by-products associated with chlorination while providing immediate feedback for operational adjustments.

Chlorination vs UV-C Disinfection Infographic

industrydif.com

industrydif.com