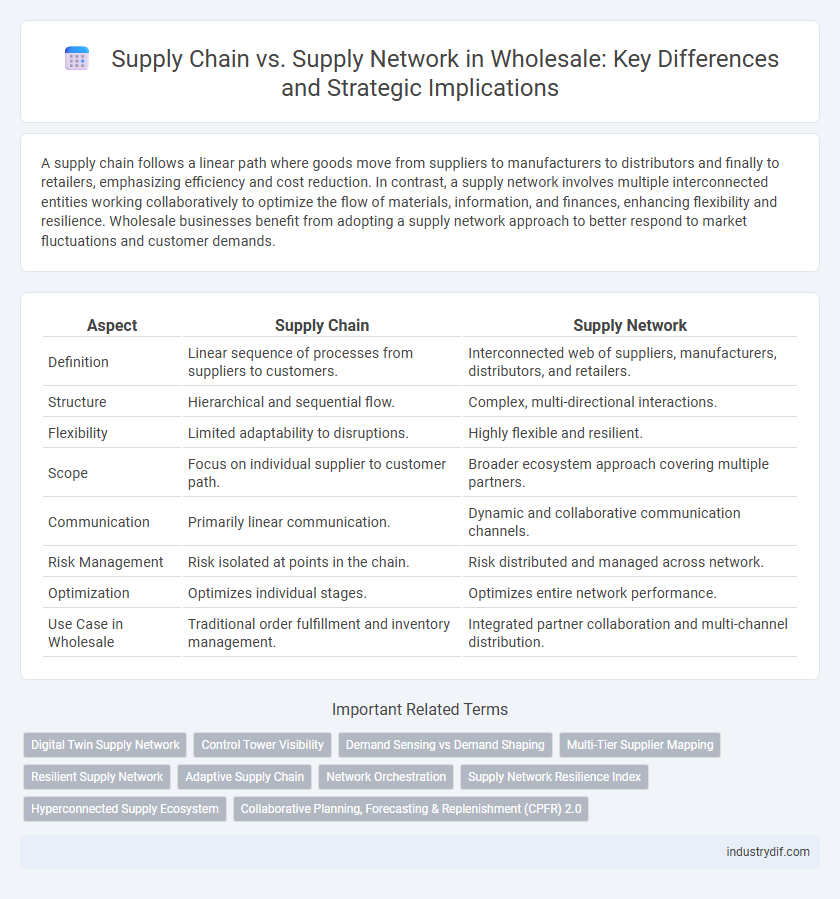

A supply chain follows a linear path where goods move from suppliers to manufacturers to distributors and finally to retailers, emphasizing efficiency and cost reduction. In contrast, a supply network involves multiple interconnected entities working collaboratively to optimize the flow of materials, information, and finances, enhancing flexibility and resilience. Wholesale businesses benefit from adopting a supply network approach to better respond to market fluctuations and customer demands.

Table of Comparison

| Aspect | Supply Chain | Supply Network |

|---|---|---|

| Definition | Linear sequence of processes from suppliers to customers. | Interconnected web of suppliers, manufacturers, distributors, and retailers. |

| Structure | Hierarchical and sequential flow. | Complex, multi-directional interactions. |

| Flexibility | Limited adaptability to disruptions. | Highly flexible and resilient. |

| Scope | Focus on individual supplier to customer path. | Broader ecosystem approach covering multiple partners. |

| Communication | Primarily linear communication. | Dynamic and collaborative communication channels. |

| Risk Management | Risk isolated at points in the chain. | Risk distributed and managed across network. |

| Optimization | Optimizes individual stages. | Optimizes entire network performance. |

| Use Case in Wholesale | Traditional order fulfillment and inventory management. | Integrated partner collaboration and multi-channel distribution. |

Introduction to Supply Chain and Supply Network

A supply chain represents a linear sequence of processes involved in producing and delivering goods from suppliers to customers, emphasizing efficiency and control. In contrast, a supply network highlights a complex, interconnected system of multiple supply chains working collaboratively to improve flexibility and resilience. Understanding the distinction between a supply chain and a supply network is crucial for optimizing wholesale operations and managing risks effectively.

Defining the Supply Chain in Wholesale

The supply chain in wholesale encompasses the end-to-end process of sourcing, purchasing, storing, and distributing goods from manufacturers to retailers or businesses. It involves key components like procurement, inventory management, warehousing, and logistics aimed at optimizing product flow and cost-efficiency. Understanding this linear structure is essential for wholesalers to maintain timely deliveries, reduce lead times, and improve customer satisfaction.

Understanding the Supply Network Concept

The supply network concept expands traditional supply chain models by emphasizing interconnected, dynamic relationships among suppliers, manufacturers, distributors, and retailers, enabling greater flexibility and resilience in wholesale operations. Unlike linear supply chains, supply networks facilitate multiple pathways for product flow and information exchange, reducing bottlenecks and improving responsiveness to market fluctuations. Understanding this complexity helps wholesalers optimize inventory management, enhance collaboration, and mitigate risks associated with disruptions in global sourcing and distribution.

Key Differences Between Supply Chain and Supply Network

Supply chains operate linearly, focusing on the flow of goods from suppliers to manufacturers to retailers, emphasizing efficiency and cost reduction. Supply networks consist of interconnected, multidimensional relationships among suppliers, manufacturers, and distributors, promoting flexibility and resilience. Key differences include the scope of collaboration, with supply chains often limited to direct partners, whereas supply networks engage multiple entities for enhanced responsiveness and innovation.

Structure and Components of Supply Chains

Supply chains consist of linear, sequential stages including suppliers, manufacturers, distributors, and retailers, emphasizing the flow of goods from raw materials to the end customer. Their components include procurement, production, inventory management, and distribution processes that coordinate to optimize efficiency and cost. Supply networks feature interconnected nodes and multiple pathways, facilitating flexible interactions and collaborations among diverse partners to enhance resilience and responsiveness.

Structure and Components of Supply Networks

Supply networks feature a complex structure comprising multiple interconnected entities such as suppliers, manufacturers, distributors, and retailers, facilitating multidirectional flow of goods, information, and finances. Unlike linear supply chains, supply networks emphasize collaboration, flexibility, and resilience through decentralized decision-making and real-time data sharing across various nodes. Key components include procurement hubs, manufacturing plants, distribution centers, and retail outlets, all synchronized via advanced logistics and integrated information systems to optimize efficiency and responsiveness in wholesale operations.

Impact on Wholesale Operations

Supply chain management in wholesale focuses on linear processes that coordinate the flow of goods from suppliers to retailers, emphasizing efficiency and cost reduction. Supply networks, however, create interconnected systems of multiple suppliers, distributors, and retailers that enhance flexibility and resilience against disruptions. This integrated approach in supply networks improves inventory management, reduces lead times, and supports dynamic demand forecasting critical for optimizing wholesale operations.

Flexibility and Resilience: Chain vs Network

Supply chains operate as linear, sequential links primarily optimized for cost efficiency, limiting their flexibility in responding to disruptions. Supply networks consist of interconnected nodes and multiple pathways, enhancing resilience by enabling rerouting and redistribution of resources when challenges arise. This network approach supports greater adaptability and risk mitigation in wholesale operations compared to traditional supply chain models.

Technology's Role in Modern Wholesale Supply Systems

Technology transforms modern wholesale supply systems by shifting from linear supply chains to dynamic, interconnected supply networks that enhance real-time data sharing and demand forecasting. Advanced tools like AI, IoT sensors, and blockchain enable seamless coordination among suppliers, manufacturers, and distributors, reducing delays and optimizing inventory management. These innovations drive efficiency, resilience, and transparency, empowering wholesalers to respond swiftly to market fluctuations and customer needs.

Future Trends: Evolving from Supply Chains to Supply Networks

Future trends in wholesale emphasize transitioning from linear supply chains to dynamic supply networks, enhancing responsiveness and resilience across multiple interconnected partners. Advanced technologies such as AI, IoT, and blockchain enable real-time data sharing and predictive analytics, optimizing inventory management and reducing disruptions. This evolution supports decentralized decision-making and sustainable practices, driving efficiency and adaptability in global wholesale operations.

Related Important Terms

Digital Twin Supply Network

A Digital Twin Supply Network (DTSN) enhances traditional supply chains by creating real-time, virtual replicas of supply network processes, enabling proactive risk management and improved decision-making. Unlike linear supply chains, supply networks modeled via DTSN integrate multi-tier suppliers, logistics, and distribution centers, optimizing visibility and responsiveness through advanced data analytics and IoT integration.

Control Tower Visibility

Supply Chain Control Tower Visibility enables real-time monitoring and centralized coordination of inventory, shipments, and supplier performance, enhancing decision-making accuracy in wholesale operations. Unlike traditional linear supply chains, supply network frameworks utilize interconnected nodes that increase agility and responsiveness, reducing disruptions through comprehensive visibility across multiple partners.

Demand Sensing vs Demand Shaping

Supply chains traditionally follow a linear flow of goods and information, relying on demand sensing techniques that analyze historical sales data to forecast future demand with greater accuracy. In contrast, supply networks adopt a more dynamic, interconnected approach that enables demand shaping by actively influencing customer demand through marketing strategies and product availability adjustments, optimizing inventory and responsiveness in wholesale distribution.

Multi-Tier Supplier Mapping

Multi-tier supplier mapping enhances visibility across the entire supply chain by identifying direct and indirect suppliers, critical for wholesale operations managing complex supply networks. This comprehensive mapping optimizes risk management, improves procurement efficiency, and strengthens supplier collaboration within multi-tier supply networks.

Resilient Supply Network

A resilient supply network in wholesale surpasses traditional linear supply chains by integrating multiple interconnected suppliers, distributors, and logistics partners to enhance adaptability and minimize disruptions. This decentralized structure leverages real-time data and collaborative planning to optimize inventory levels, reduce lead times, and ensure continuous product availability.

Adaptive Supply Chain

An adaptive supply chain integrates real-time data analytics and flexible logistics to respond swiftly to market fluctuations, outperforming traditional linear supply networks. Emphasizing collaboration among suppliers, manufacturers, and distributors enhances resilience and agility, driving efficiency in wholesale operations.

Network Orchestration

Supply network orchestration enhances wholesale efficiency by integrating multiple suppliers, manufacturers, and distributors into a cohesive system that optimizes inventory flow and reduces lead times. This dynamic coordination leverages real-time data analytics and collaboration tools to improve responsiveness and scalability compared to traditional linear supply chain models.

Supply Network Resilience Index

The Supply Network Resilience Index measures the ability of interconnected suppliers, distributors, and retailers within a wholesale supply network to withstand disruptions and maintain operational continuity. This index evaluates factors such as supplier diversity, network flexibility, and information sharing to enhance risk mitigation compared to traditional linear supply chain models.

Hyperconnected Supply Ecosystem

A hyperconnected supply ecosystem transforms traditional supply chains into dynamic supply networks by integrating real-time data, advanced analytics, and IoT technologies to enhance visibility, agility, and collaboration among wholesale partners. This interconnected framework reduces bottlenecks, optimizes inventory management, and accelerates decision-making processes, enabling wholesalers to respond swiftly to market fluctuations and customer demands.

Collaborative Planning, Forecasting & Replenishment (CPFR) 2.0

Collaborative Planning, Forecasting & Replenishment (CPFR) 2.0 enhances wholesale supply networks by integrating real-time data sharing and predictive analytics, enabling synchronized demand forecasting and optimized inventory replenishment across multiple partners. This shift from traditional linear supply chains to dynamic, interconnected supply networks improves responsiveness, reduces stockouts, and drives cost efficiency throughout the wholesale distribution ecosystem.

Supply Chain vs Supply Network Infographic

industrydif.com

industrydif.com