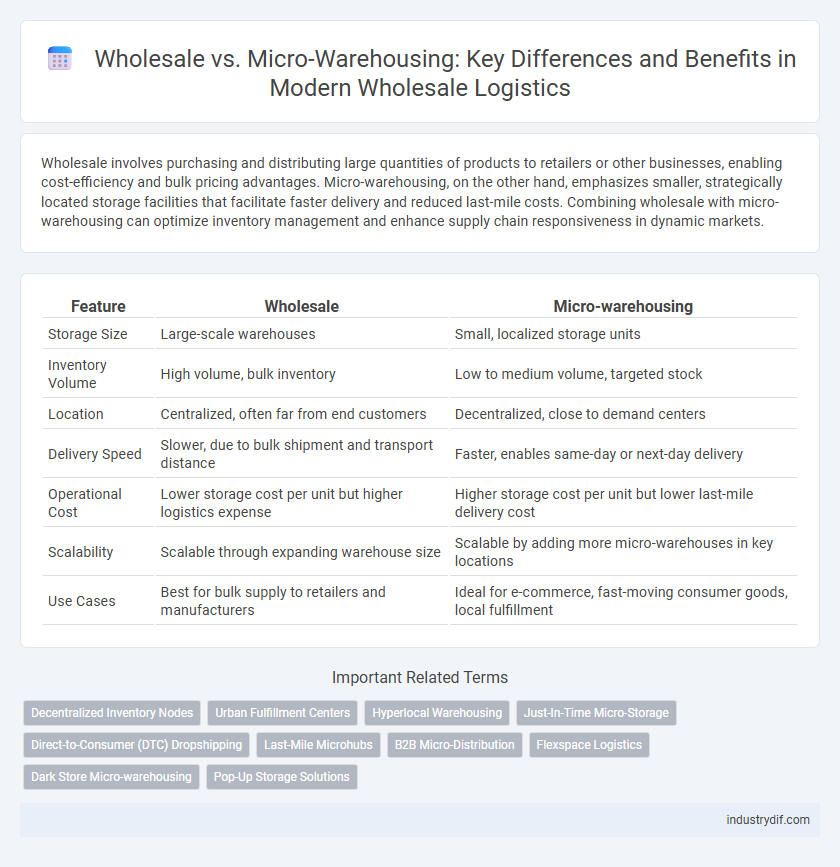

Wholesale involves purchasing and distributing large quantities of products to retailers or other businesses, enabling cost-efficiency and bulk pricing advantages. Micro-warehousing, on the other hand, emphasizes smaller, strategically located storage facilities that facilitate faster delivery and reduced last-mile costs. Combining wholesale with micro-warehousing can optimize inventory management and enhance supply chain responsiveness in dynamic markets.

Table of Comparison

| Feature | Wholesale | Micro-warehousing |

|---|---|---|

| Storage Size | Large-scale warehouses | Small, localized storage units |

| Inventory Volume | High volume, bulk inventory | Low to medium volume, targeted stock |

| Location | Centralized, often far from end customers | Decentralized, close to demand centers |

| Delivery Speed | Slower, due to bulk shipment and transport distance | Faster, enables same-day or next-day delivery |

| Operational Cost | Lower storage cost per unit but higher logistics expense | Higher storage cost per unit but lower last-mile delivery cost |

| Scalability | Scalable through expanding warehouse size | Scalable by adding more micro-warehouses in key locations |

| Use Cases | Best for bulk supply to retailers and manufacturers | Ideal for e-commerce, fast-moving consumer goods, local fulfillment |

Understanding Wholesale: Definition and Evolution

Wholesale involves the bulk purchase and sale of goods primarily for resale by retailers or other businesses, serving as a critical link in the supply chain. Micro-warehousing represents an evolution in wholesale distribution, emphasizing smaller, strategically located storage facilities to enhance inventory management and speed up delivery. This shift reflects changing market demands for faster fulfillment and greater flexibility in handling diverse product assortments.

What is Micro-warehousing? Key Concepts Explained

Micro-warehousing involves strategically located small-scale storage facilities designed to optimize last-mile delivery efficiency in wholesale distribution. Key concepts include inventory decentralization, real-time stock visibility, and rapid replenishment to meet fluctuating local demand. This approach contrasts with traditional wholesale models by reducing lead times, lowering transportation costs, and enhancing customer satisfaction through faster order fulfillment.

Core Differences: Wholesale vs Micro-warehousing

Wholesale involves sourcing and selling large quantities of products to retailers or businesses, prioritizing bulk inventory and centralized distribution centers for cost efficiency. Micro-warehousing operates with small, strategically located storage units that enable faster delivery and enhanced customer proximity, focusing on agility and localized stock management. The core difference lies in scale and distribution strategy, with wholesale emphasizing volume and cost savings, while micro-warehousing prioritizes speed and flexibility in fulfillment.

Inventory Management: Centralized vs Decentralized Approaches

Wholesale inventory management typically relies on centralized warehousing, enabling bulk storage and streamlined stock control that reduces overhead costs and simplifies replenishment processes. Micro-warehousing adopts a decentralized approach by placing smaller inventory hubs closer to end consumers, enhancing responsiveness and reducing last-mile delivery times. Balancing centralized and decentralized systems optimizes inventory turnover, minimizes stockouts, and aligns supply chain agility with market demand fluctuations.

Order Fulfillment Speed: Wholesale vs Micro-warehousing Models

Wholesale distribution relies on bulk inventory storage in centralized warehouses, resulting in longer order fulfillment times due to distance and volume processing. Micro-warehousing strategically positions smaller inventory hubs closer to end customers, significantly reducing delivery times and increasing order fulfillment speed. This localized approach enables faster shipping, enhanced responsiveness, and improved customer satisfaction in competitive markets.

Scalability and Flexibility: Comparing Business Growth Potential

Wholesale distribution offers significant scalability by enabling bulk purchasing and storage in large centralized warehouses, supporting rapid expansion and high-volume order fulfillment. Micro-warehousing provides enhanced flexibility with strategically located smaller storage units, facilitating quicker delivery and localized inventory management that adapt to fluctuating market demands. Businesses aiming for scalable growth often prefer wholesale models for volume efficiency, while those prioritizing agile response to regional trends benefit from micro-warehousing's flexible distribution networks.

Cost Structures: Wholesale Distribution vs Micro-warehousing Expenses

Wholesale distribution typically involves large-scale inventory storage and centralized warehouses, leading to higher fixed costs such as rent, utilities, and labor. Micro-warehousing reduces these costs by utilizing smaller, strategically located facilities that minimize last-mile delivery expenses and improve inventory turnover rates. However, micro-warehousing may incur higher variable costs due to increased logistics complexity and the need for advanced inventory management systems.

Impact on Last-mile Delivery Logistics

Wholesale distribution relies on centralized inventory management, which often results in longer last-mile delivery times due to extended shipping routes. In contrast, micro-warehousing strategically places small inventory hubs closer to end consumers, significantly reducing delivery distance and improving speed. This shift enhances last-mile logistics efficiency by lowering transportation costs and increasing delivery reliability.

Technology Integration: Automation and Data Analytics in Both Models

Wholesale operations leverage advanced automation systems and data analytics to optimize inventory management, streamline order fulfillment, and enhance supply chain visibility. Micro-warehousing integrates similar technology on a smaller scale, focusing on real-time data to improve last-mile delivery efficiency and adaptive stocking based on localized demand patterns. Both models invest in AI-driven analytics and robotics to reduce operational costs and increase accuracy in inventory tracking and forecasting.

Choosing the Right Model: Factors for Businesses to Consider

Choosing the right distribution model requires evaluating order volume, delivery speed, and inventory management costs. Wholesale offers bulk purchasing advantages and lower per-unit costs, ideal for high-demand products and established supply chains. Micro-warehousing supports faster delivery and localized stock, benefiting businesses targeting urban customers with frequent, small orders.

Related Important Terms

Decentralized Inventory Nodes

Decentralized inventory nodes in wholesale optimize stock distribution by placing micro-warehouses closer to end customers, reducing delivery times and lowering transportation costs. This strategy enhances supply chain flexibility and responsiveness compared to traditional centralized wholesale warehouses.

Urban Fulfillment Centers

Urban fulfillment centers enhance wholesale distribution by offering micro-warehousing solutions that reduce delivery times and improve inventory accuracy in densely populated areas. This strategy optimizes last-mile logistics by strategically positioning smaller storage facilities closer to end customers, lowering transportation costs and increasing order fulfillment speed.

Hyperlocal Warehousing

Hyperlocal warehousing optimizes wholesale distribution by positioning inventory closer to end consumers, significantly reducing delivery times and last-mile logistics costs. This approach enhances supply chain agility and responsiveness compared to traditional centralized wholesale models, supporting faster fulfillment in densely populated urban areas.

Just-In-Time Micro-Storage

Just-In-Time Micro-Storage in wholesale streamlines inventory by reducing bulk stock and enabling rapid replenishment through strategically located micro-warehouses. This approach enhances supply chain efficiency, minimizes holding costs, and meets customer demand with greater agility compared to traditional wholesale bulk storage.

Direct-to-Consumer (DTC) Dropshipping

Wholesale enables bulk purchasing and broad inventory management, offering cost advantages for Direct-to-Consumer (DTC) dropshipping by streamlining supply chains and reducing fulfillment times. Micro-warehousing complements this by positioning smaller stock units closer to end customers, enhancing delivery speed and reducing shipping costs in DTC dropshipping operations.

Last-Mile Microhubs

Last-mile microhubs serve as critical nodes in wholesale distribution, optimizing inventory storage closer to end consumers and reducing delivery times compared to traditional wholesale warehouses. These micro-warehousing solutions enhance supply chain agility by enabling faster order fulfillment, lowering transportation costs, and improving scalability for high-demand urban markets.

B2B Micro-Distribution

B2B micro-distribution leverages micro-warehousing to enhance wholesale efficiency by strategically positioning smaller inventory hubs closer to end customers, reducing delivery times and transportation costs. This model supports agile supply chains and real-time inventory management, enabling wholesalers to meet dynamic demand patterns with greater precision and flexibility.

Flexspace Logistics

Flexspace Logistics revolutionizes wholesale distribution by integrating micro-warehousing solutions that optimize inventory management and reduce last-mile delivery times. Their hybrid model enhances supply chain efficiency by strategically positioning smaller storage units closer to end customers while maintaining bulk wholesale operations in centralized facilities.

Dark Store Micro-warehousing

Wholesale operations benefit from economies of scale but often face challenges in rapid order fulfillment, whereas Dark Store Micro-warehousing enables hyper-local inventory management to boost delivery speed and reduce last-mile costs. Dark Store Micro-warehousing leverages strategically located, highly optimized fulfillment centers that function exclusively for online orders, enhancing agility and customer satisfaction in the wholesale distribution network.

Pop-Up Storage Solutions

Pop-up storage solutions in wholesale offer flexible, temporary warehousing options that reduce overhead costs and improve inventory accessibility compared to traditional micro-warehousing. These scalable storage setups enable businesses to quickly respond to fluctuating demand and optimize supply chain efficiency without long-term lease commitments.

Wholesale vs Micro-warehousing Infographic

industrydif.com

industrydif.com