Wholesale offers bulk purchasing at lower costs, enabling higher profit margins and quicker inventory turnover compared to print-on-demand, which operates on a per-item basis with no upfront stock investment. Print-on-demand minimizes risk by producing items only after a customer order is placed, ideal for testing new designs or markets without inventory commitments. Choosing between wholesale and print-on-demand depends on business goals, cash flow, and willingness to manage stock versus flexibility.

Table of Comparison

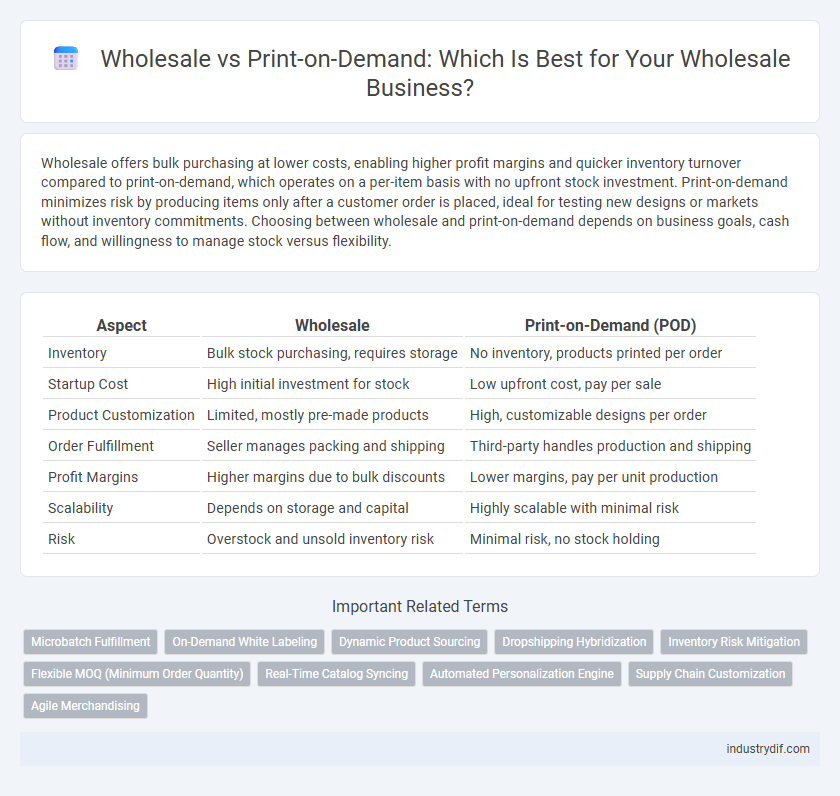

| Aspect | Wholesale | Print-on-Demand (POD) |

|---|---|---|

| Inventory | Bulk stock purchasing, requires storage | No inventory, products printed per order |

| Startup Cost | High initial investment for stock | Low upfront cost, pay per sale |

| Product Customization | Limited, mostly pre-made products | High, customizable designs per order |

| Order Fulfillment | Seller manages packing and shipping | Third-party handles production and shipping |

| Profit Margins | Higher margins due to bulk discounts | Lower margins, pay per unit production |

| Scalability | Depends on storage and capital | Highly scalable with minimal risk |

| Risk | Overstock and unsold inventory risk | Minimal risk, no stock holding |

Definition of Wholesale and Print-on-Demand

Wholesale refers to the practice of purchasing goods in large quantities directly from manufacturers or distributors at a discounted rate to resell them at retail prices. Print-on-Demand is a fulfillment method where products, typically customized merchandise like apparel or books, are printed only after an order is received, eliminating the need for inventory. While wholesale requires upfront inventory investment, print-on-demand operates on a just-in-time production model, reducing storage costs and minimizing financial risk.

Key Differences Between Wholesale and Print-on-Demand

Wholesale involves purchasing large quantities of products at a discounted rate for resale, enabling bulk inventory management and lower per-unit costs. Print-on-Demand (POD) allows sellers to produce items only after an order is placed, reducing upfront investment and eliminating inventory storage but often with higher per-item costs. Key differences include inventory risk, upfront costs, customization options, and fulfillment speed, with wholesale favoring volume and POD prioritizing flexibility and personalization.

Pros and Cons of Wholesale

Wholesale offers bulk purchasing at significantly lower costs per unit, enabling higher profit margins for retailers. Inventory management and upfront investment risks are major drawbacks, as unsold stock can lead to financial loss and storage expenses. Wholesale is ideal for businesses prioritizing consistent product availability and control over supply chains.

Pros and Cons of Print-on-Demand

Print-on-demand offers low upfront costs and eliminates inventory risks, making it ideal for testing designs and customizing products on demand. However, it often results in higher per-unit costs and longer fulfillment times compared to wholesale purchasing, which benefits from bulk discounts and faster shipping. Quality variability and limited brand control are additional challenges in print-on-demand models versus wholesale sourcing.

Cost Analysis: Wholesale vs Print-on-Demand

Wholesale offers lower per-unit costs due to bulk purchasing, significantly reducing overall expenses compared to print-on-demand, which incurs higher per-item charges due to individual production. Print-on-demand eliminates inventory risks and upfront investment but results in increased costs per product that can reduce profit margins. Businesses must weigh the scalability and cost efficiency of wholesale against the flexibility and lower initial outlay of print-on-demand when selecting their fulfillment method.

Inventory Management in Wholesale and Print-on-Demand

Wholesale requires maintaining significant inventory levels, which involves upfront costs and risks of overstock or stockouts, impacting cash flow and storage expenses. Print-on-Demand eliminates the need for inventory by producing items only after an order is placed, reducing financial risk and warehousing requirements. Effective inventory management in wholesale demands accurate demand forecasting and supply chain coordination, whereas print-on-demand leverages real-time production data to fulfill orders just-in-time.

Product Customization: Opportunities and Limitations

Wholesale offers limited product customization, as items are typically mass-produced with fixed designs and specifications, making it challenging to meet unique customer preferences. Print-on-Demand (POD) excels in customization by allowing businesses to create personalized products on order, reducing inventory risk and enabling endless design variations. However, POD often faces higher per-unit costs and longer production times compared to wholesale, which benefits from economies of scale and faster bulk fulfillment.

Scalability and Growth Potential

Wholesale offers significant scalability through bulk purchasing and inventory control, enabling faster order fulfillment and consistent product availability. Print-on-demand limits upfront investment but faces growth constraints due to individualized production times and higher per-unit costs. Businesses prioritizing rapid expansion and predictable cash flow often favor wholesale models for their robust growth potential.

Choosing the Right Model for Your Business

Wholesale offers bulk purchasing at reduced costs, ideal for businesses seeking consistent inventory and higher profit margins. Print-on-demand allows for customized products with minimal upfront investment, suited for businesses prioritizing flexibility and low risk. Selecting the right model depends on factors like cash flow, inventory management capabilities, and target market demand.

Future Trends in Wholesale and Print-on-Demand

Wholesale is expected to integrate advanced automation and AI technologies to streamline inventory management and demand forecasting, enhancing operational efficiency. Print-on-demand continues to grow with personalized product offerings and eco-friendly printing methods driving consumer preference toward sustainable and customized purchases. The convergence of wholesale and print-on-demand models will likely create hybrid supply chains, enabling faster turnaround times and reduced waste in the retail industry.

Related Important Terms

Microbatch Fulfillment

Microbatch fulfillment in wholesale enables businesses to order smaller quantities at reduced costs compared to traditional print-on-demand models, improving inventory control and minimizing waste. This approach combines the efficiency of bulk purchasing with the customization benefits of print-on-demand, optimizing supply chain management for faster delivery and higher profit margins.

On-Demand White Labeling

On-demand white labeling offers businesses the ability to customize products with their own branding without the need for large inventory investments, contrasting traditional wholesale models that require bulk purchasing and storage. This approach enables faster market responsiveness and personalized product offerings, driving higher profit margins and customer loyalty through unique, branded merchandise.

Dynamic Product Sourcing

Dynamic product sourcing in wholesale allows businesses to maintain large inventories with cost-effective bulk purchasing, ensuring consistent product availability and faster fulfillment times compared to print-on-demand. Print-on-demand offers flexibility with on-demand customization but often results in higher per-unit costs and longer delivery times, making wholesale preferable for scaling with consistent demand.

Dropshipping Hybridization

Wholesale enables bulk purchasing at reduced costs, maximizing profit margins, while print-on-demand specializes in customizable products with minimal inventory risk; dropshipping hybridization combines these models by allowing retailers to stock bulk items alongside on-demand products, optimizing inventory management and expanding product offerings without significant upfront investment. This integration leverages the efficiency of wholesale pricing with the flexibility of print-on-demand dropshipping, creating a scalable and diversified e-commerce strategy.

Inventory Risk Mitigation

Wholesale involves purchasing bulk inventory upfront, which can lead to higher inventory risk due to unsold stock, whereas print-on-demand minimizes this risk by producing items only after receiving customer orders, eliminating the need for large inventory holding. Print-on-demand's just-in-time production model significantly reduces the financial burden of excess inventory, making it a more flexible option for businesses aiming to mitigate inventory risk.

Flexible MOQ (Minimum Order Quantity)

Wholesale offers lower prices per unit but typically requires a higher MOQ, making it ideal for businesses with larger capital and storage capacity; print-on-demand provides flexible MOQ options starting at one unit, allowing smaller sellers to reduce inventory risk and upfront investment. Choosing between wholesale and print-on-demand depends on balancing bulk discount advantages against the flexibility of producing items as needed.

Real-Time Catalog Syncing

Wholesale platforms offer real-time catalog syncing, ensuring instant updates on inventory levels, pricing, and product availability across multiple sales channels. Print-on-demand services typically lack this seamless synchronization, leading to potential delays and discrepancies in product listings and fulfillment.

Automated Personalization Engine

Wholesale requires bulk inventory management, while print-on-demand leverages an automated personalization engine that customizes products in real-time without holding stock. This technology enables seamless scalability and reduces overhead by automating individual order customization based on customer data.

Supply Chain Customization

Wholesale offers greater supply chain customization by enabling bulk purchasing, inventory control, and tailored packaging options, which streamline distribution efficiency. Print-on-Demand limits customization due to on-demand production constraints and reliance on third-party suppliers, often resulting in longer lead times and less control over product personalization.

Agile Merchandising

Wholesale enables agile merchandising by offering bulk inventory that can be rapidly adjusted based on market demands, reducing lead times and stockouts. Print-on-demand lacks this flexibility, as products are made per order, limiting responsiveness to trending merchandise fluctuations.

Wholesale vs Print-on-Demand Infographic

industrydif.com

industrydif.com