Crane operators specialize in maneuvering heavy lifting equipment to transport materials safely and efficiently on construction sites, relying heavily on physical control and spatial awareness. Robotics operators, however, utilize advanced automated systems and programmable machinery to perform precise tasks, often enhancing safety and productivity in hazardous environments. The integration of robotics in construction is reshaping traditional roles, demanding technical expertise in automation alongside conventional operating skills.

Table of Comparison

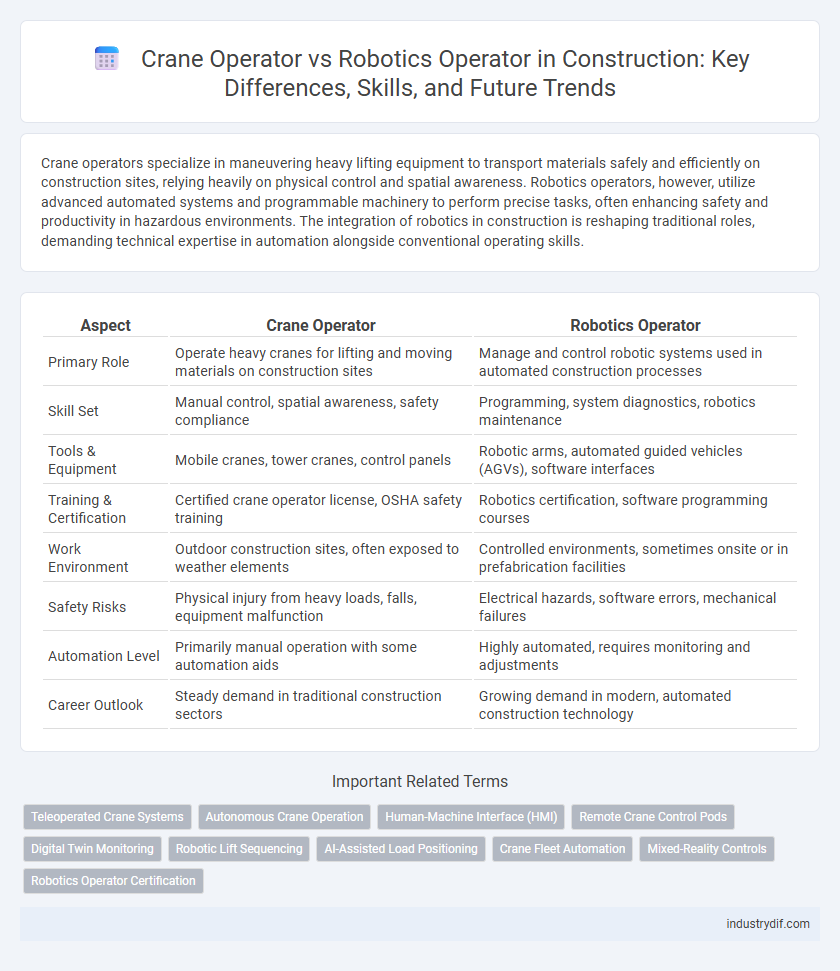

| Aspect | Crane Operator | Robotics Operator |

|---|---|---|

| Primary Role | Operate heavy cranes for lifting and moving materials on construction sites | Manage and control robotic systems used in automated construction processes |

| Skill Set | Manual control, spatial awareness, safety compliance | Programming, system diagnostics, robotics maintenance |

| Tools & Equipment | Mobile cranes, tower cranes, control panels | Robotic arms, automated guided vehicles (AGVs), software interfaces |

| Training & Certification | Certified crane operator license, OSHA safety training | Robotics certification, software programming courses |

| Work Environment | Outdoor construction sites, often exposed to weather elements | Controlled environments, sometimes onsite or in prefabrication facilities |

| Safety Risks | Physical injury from heavy loads, falls, equipment malfunction | Electrical hazards, software errors, mechanical failures |

| Automation Level | Primarily manual operation with some automation aids | Highly automated, requires monitoring and adjustments |

| Career Outlook | Steady demand in traditional construction sectors | Growing demand in modern, automated construction technology |

Overview: Crane Operator vs Robotics Operator

Crane operators control heavy machinery to lift and move materials on construction sites, requiring expertise in equipment handling and safety protocols. Robotics operators manage automated systems and robotic equipment, integrating advanced technology to perform tasks with precision and efficiency. Both roles demand specialized training but differ in their interaction with manual machinery versus automated robotics technology.

Critical Skills Required

Crane operators require advanced spatial awareness, precise hand-eye coordination, and in-depth knowledge of load dynamics to safely maneuver heavy equipment on construction sites. Robotics operators must possess strong programming skills, expertise in automated control systems, and the ability to troubleshoot complex robotic machinery. Both roles demand keen attention to safety protocols and real-time problem-solving abilities to ensure efficient and secure operations.

Training and Certification Differences

Crane operators typically require certification from organizations such as NCCCO, involving hands-on training, safety courses, and practical exams on heavy machinery operation. Robotics operators in construction must undergo specialized training focused on programming, system diagnostics, and automation safety, often requiring technical certifications in robotics or mechatronics. The certification for crane operators emphasizes physical control and safety compliance with OSHA standards, whereas robotics operators prioritize software proficiency and integration with construction technology systems.

Technological Advancements in Each Role

Crane operators utilize advanced telematics and sensor technologies to enhance precision and safety in lifting operations, integrating GPS and IoT for real-time monitoring and predictive maintenance. Robotics operators leverage AI-driven automation and machine learning algorithms to control autonomous construction machinery, allowing for greater efficiency and reduced human error in repetitive tasks. Both roles are evolving rapidly with Industry 4.0, focusing on digital interfaces and remote operation capabilities that maximize productivity on modern construction sites.

Daily Responsibilities on-site

Crane operators are responsible for maneuvering heavy lifting equipment to move materials and equipment safely and precisely on construction sites, requiring strong spatial awareness and adherence to safety protocols. Robotics operators manage automated machinery and robotic systems, programming and monitoring equipment to perform repetitive tasks like welding, bricklaying, or inspection, enhancing efficiency and reducing manual labor. Both roles demand technical expertise but differ in hands-on control versus system oversight within construction workflows.

Safety Protocols and Challenges

Crane operators must rigorously follow safety protocols such as load capacity limits, pre-operation inspections, and clear communication signals to prevent accidents on construction sites. Robotics operators face challenges in programming precise movements and ensuring machines interact safely with human workers while adhering to automated safety systems and emergency shutoffs. Both roles require comprehensive training and adherence to safety standards to mitigate risks associated with heavy machinery operation and evolving construction technologies.

Impact on Project Efficiency

Crane operators enhance project efficiency by providing precise control over heavy lifting tasks, reducing downtime and minimizing safety risks on construction sites. Robotics operators manage automated machinery that speeds up repetitive processes, improving accuracy and consistency while lowering labor costs. Integrating both roles optimizes workflow, accelerates project timelines, and increases overall productivity in construction projects.

Career Pathways and Opportunities

Crane operators primarily advance through certifications and hands-on experience in heavy machinery handling, often progressing to supervisory roles in large construction projects. Robotics operators specialize in programming and maintaining automated systems, with career opportunities expanding into industrial automation and smart construction technologies. Both pathways offer robust job stability, but robotics operators benefit from a faster growth trajectory due to increasing adoption of AI-driven equipment in modern construction sites.

Wages and Job Market Trends

Crane operators in the construction industry typically earn median wages ranging from $45,000 to $65,000 annually, driven by steady demand in infrastructure projects and commercial development. Robotics operators, a rapidly growing field, command higher salaries averaging $60,000 to $80,000 due to the specialized technical skills required and increasing automation in construction processes. Job market trends indicate a stronger growth rate for robotics operators as construction firms invest in advanced technologies to enhance efficiency and safety on job sites.

Future Outlook in Construction Industry

Crane operators and robotics operators both play critical roles in the construction industry's future, with robotics operators increasingly vital due to automation trends and smart technology integration. The demand for robotics operators is projected to grow significantly as advanced machinery enhances efficiency, safety, and precision on construction sites. Crane operators will continue to be essential but must adapt by acquiring skills to work alongside robotic equipment and automated systems.

Related Important Terms

Teleoperated Crane Systems

Teleoperated crane systems blend human precision with robotic technology, allowing crane operators to control heavy machinery remotely, enhancing safety and operational efficiency on construction sites. Robotics operators specialize in managing automated systems, but teleoperated crane technology uniquely requires crane operators to adapt their skills to remote control interfaces for improved maneuverability and reduced on-site risks.

Autonomous Crane Operation

Autonomous crane operation integrates advanced robotics and AI technology to enhance precision, safety, and efficiency on construction sites, reducing the need for manual crane operators. Robotics operators oversee automated crane systems that perform heavy lifting tasks with minimal human intervention, enabling real-time monitoring and adaptive control for complex construction projects.

Human-Machine Interface (HMI)

Crane operators rely on tactile controls and direct visual cues to navigate complex construction environments, leveraging their experience with Human-Machine Interface (HMI) systems designed for manual precision and safety. Robotics operators, however, interface with advanced programmable HMIs that integrate sensor data and automated feedback loops, enabling remote or semi-autonomous operation to enhance efficiency and reduce human error on construction sites.

Remote Crane Control Pods

Crane operators skilled in traditional manual controls face increasing integration of robotics operators who utilize advanced remote crane control pods to enhance precision and safety on construction sites. These remote control systems reduce operator exposure to hazardous environments, improve maneuverability for complex lifts, and streamline project timelines through real-time data feedback and automation.

Digital Twin Monitoring

Crane operators and robotics operators increasingly rely on digital twin monitoring to enhance precision and safety in construction projects by providing real-time, virtual replicas of physical equipment and environments. This technology enables predictive maintenance and remote operation, reducing downtime and improving overall efficiency on-site.

Robotic Lift Sequencing

Robotic lift sequencing enhances construction site efficiency by precisely coordinating robotic arm movements to optimize load handling, reducing the margin of error compared to traditional crane operator techniques. This technology integrates advanced sensors and AI algorithms to automate complex lift patterns, significantly improving safety and productivity on modern construction projects.

AI-Assisted Load Positioning

AI-assisted load positioning enhances crane operators' precision by integrating advanced sensors and real-time data analysis, reducing human error during complex lifts. Robotics operators leverage automated systems and machine learning algorithms to execute repetitive tasks with consistent accuracy, significantly increasing operational efficiency on construction sites.

Crane Fleet Automation

Crane fleet automation enhances construction efficiency by integrating advanced robotics operators with traditional crane operators, enabling precise remote control and reducing on-site labor risks. Robotics operators utilize AI-driven systems to optimize crane movements, increase safety, and improve project timelines compared to conventional manual crane operation.

Mixed-Reality Controls

Crane operators employing mixed-reality controls benefit from enhanced spatial awareness and precision during complex lifts, enabling safer and more efficient construction site operations. Robotics operators leverage mixed-reality interfaces to remotely manage automated machinery, improving task accuracy and reducing on-site hazards in construction environments.

Robotics Operator Certification

Robotics Operator Certification in construction ensures proficiency in controlling automated machinery, enhancing efficiency and safety on site compared to traditional crane operators. Certified Robotics Operators possess specialized knowledge in programming, troubleshooting, and maintaining robotic systems, critical for modern automated construction environments.

Crane Operator vs Robotics Operator Infographic

industrydif.com

industrydif.com