Manual welding offers greater flexibility and precision for complex, small-scale projects requiring skilled craftsmanship. Robotic welding ensures higher consistency, faster production rates, and improved safety by minimizing human exposure to hazardous environments. Choosing between manual and robotic welding depends on project scale, budget, and desired production efficiency.

Table of Comparison

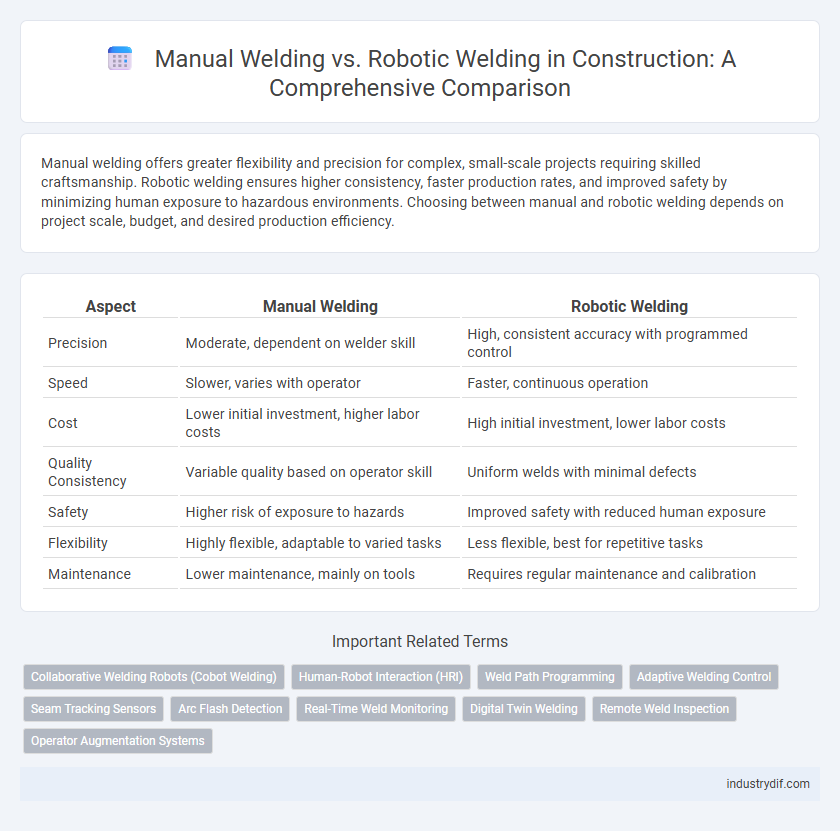

| Aspect | Manual Welding | Robotic Welding |

|---|---|---|

| Precision | Moderate, dependent on welder skill | High, consistent accuracy with programmed control |

| Speed | Slower, varies with operator | Faster, continuous operation |

| Cost | Lower initial investment, higher labor costs | High initial investment, lower labor costs |

| Quality Consistency | Variable quality based on operator skill | Uniform welds with minimal defects |

| Safety | Higher risk of exposure to hazards | Improved safety with reduced human exposure |

| Flexibility | Highly flexible, adaptable to varied tasks | Less flexible, best for repetitive tasks |

| Maintenance | Lower maintenance, mainly on tools | Requires regular maintenance and calibration |

Introduction to Manual and Robotic Welding

Manual welding involves skilled workers using handheld tools to fuse metals, allowing for precise control in complex or custom tasks. Robotic welding employs automated machines programmed to perform consistent and high-speed welds, enhancing efficiency and repeatability in large-scale construction projects. Both techniques are critical in construction, with manual welding preferred for detail-oriented work and robotic welding ideal for repetitive, high-volume fabrication.

Key Differences Between Manual and Robotic Welding

Manual welding relies on skilled welders to control the welding process, offering high flexibility for complex or custom tasks, while robotic welding uses automated machines for consistent, high-speed production. The precision of robotic welding reduces human error and improves weld quality, making it ideal for repetitive tasks in large-scale construction projects. Cost-efficiency varies as manual welding requires lower initial investment but higher labor expenses, whereas robotic welding demands significant upfront costs with long-term savings through increased productivity.

Advantages of Manual Welding

Manual welding offers superior control and precision, allowing skilled welders to adapt techniques in real-time for complex or detailed construction projects. It enables better handling of irregular surfaces and intricate joints, which robotic systems may struggle to navigate effectively. This flexibility makes manual welding essential for custom fabrication and repairs in diverse construction environments.

Benefits of Robotic Welding

Robotic welding significantly enhances construction efficiency by delivering consistent, high-quality welds that reduce human error and material waste. It improves safety on job sites by minimizing worker exposure to hazardous fumes and intense heat, lowering the risk of accidents. The automation accelerates project timelines through continuous operation and precise control, ultimately reducing labor costs and increasing overall productivity.

Cost Comparison: Manual vs Robotic Welding

Manual welding typically incurs higher labor costs due to the need for skilled welders and longer project durations, while robotic welding requires substantial upfront investment in automation technology but reduces labor expenses over time. Robotic welding enhances efficiency and consistency, lowering overall production costs through increased throughput and minimized rework. Cost savings from robotic welding grow significantly in large-scale construction projects, where repetitive welding tasks benefit from automation's precision and speed.

Skill Requirements and Workforce Implications

Manual welding demands highly skilled craftsmen proficient in various welding techniques, leading to extensive training periods and reliance on individual expertise. Robotic welding minimizes the need for manual dexterity, shifting workforce requirements toward programming, maintenance, and operation of automated systems. This transition influences labor dynamics by reducing manual labor demand while increasing the need for technically skilled operators and engineers in construction projects.

Precision and Quality Control in Welding Methods

Manual welding offers skilled operators the ability to adjust techniques in real-time, but it often results in variability in precision and quality control due to human factors. Robotic welding systems deliver consistent, high-precision welds by utilizing programmed controls that reduce defects and enhance repeatability across large-scale construction projects. The integration of sensors and automated quality inspection in robotic setups further elevates weld integrity, minimizing rework and ensuring compliance with stringent construction standards.

Safety Considerations in Manual and Robotic Welding

Manual welding exposes workers to high risks of burns, harmful fumes, and electric shock, requiring strict use of personal protective equipment (PPE) and comprehensive safety training. Robotic welding significantly reduces direct human exposure to hazardous environments by automating the welding process, improving workplace safety and minimizing accidents. However, robotic systems demand rigorous maintenance protocols and safety barriers to prevent malfunctions and ensure operator protection.

Applications in the Construction Industry

Manual welding remains essential for intricate construction tasks requiring precise control and adaptability, such as custom steel frameworks and repair work on-site. Robotic welding excels in large-scale structural fabrications, delivering consistent weld quality and increased speed for repetitive tasks like beam assembly and pipeline construction. Implementing both methods strategically optimizes productivity and ensures high safety standards across diverse construction projects.

Future Trends in Welding Technology

Future trends in welding technology emphasize increased integration of robotic welding systems, driven by advancements in artificial intelligence and machine learning that enhance precision and efficiency. Manual welding remains essential for complex, custom tasks, but the shift towards automation reduces human error and labor costs, optimizing construction timelines. Emerging technologies like augmented reality for operator training and real-time weld quality monitoring are set to revolutionize both manual and robotic welding practices in construction.

Related Important Terms

Collaborative Welding Robots (Cobot Welding)

Collaborative welding robots (cobot welding) enhance construction efficiency by enabling precise, repeatable welds alongside human operators, reducing labor costs and minimizing errors compared to manual welding. These cobots improve safety and productivity on construction sites by automating repetitive welding tasks while allowing skilled workers to focus on complex activities.

Human-Robot Interaction (HRI)

Human-Robot Interaction (HRI) in construction welding enhances precision and safety by integrating robotic welding systems with skilled human operators who oversee and adjust processes in real-time. Combining manual welding adaptability with robotic consistency improves efficiency while reducing errors and ergonomic risks in complex structural assemblies.

Weld Path Programming

Manual welding relies heavily on the welder's skill to interpret weld path programming through visual guidance and experience, which can result in variability in weld quality and productivity. Robotic welding utilizes precise, computer-controlled weld path programming that enhances consistency, accuracy, and efficiency in repetitive construction tasks.

Adaptive Welding Control

Adaptive welding control enhances both manual and robotic welding by continuously monitoring parameters such as arc voltage, current, and travel speed to adjust in real-time for optimal weld quality. Robotic welding benefits significantly from this technology, achieving higher precision, consistent welds, and reduced defect rates compared to manual welding, which relies heavily on operator skill for adjustments.

Seam Tracking Sensors

Seam tracking sensors in robotic welding enhance precision by continuously detecting and adjusting the welding path, significantly reducing defects compared to manual welding. These sensors optimize seam alignment and consistency, resulting in faster production rates and improved structural integrity in construction projects.

Arc Flash Detection

Arc flash detection in manual welding relies heavily on the welder's awareness and personal protective equipment, whereas robotic welding integrates advanced sensors and real-time monitoring systems to identify arc flash incidents instantly. This automation enhances safety by minimizing human exposure to hazardous arc flash events and ensuring rapid response to potential electrical hazards on construction sites.

Real-Time Weld Monitoring

Real-time weld monitoring in manual welding relies heavily on the welder's skill and experience to detect defects, often leading to variability in quality and increased inspection times. Robotic welding systems integrated with advanced sensors and AI-driven analytics enable consistent, automated real-time monitoring, significantly improving weld accuracy, reducing errors, and enhancing overall construction project efficiency.

Digital Twin Welding

Digital Twin Welding integrates manual welding data with robotic system analytics to enhance precision, reduce errors, and optimize weld quality in construction projects. This technology leverages real-time simulations and predictive modeling to improve process control and minimize costly rework.

Remote Weld Inspection

Remote weld inspection enhances quality control in both manual and robotic welding by enabling real-time monitoring through high-resolution cameras and sensors, reducing human error and increasing efficiency. Integration of AI-powered analytics allows precise defect detection and structural integrity assessment, optimizing construction project timelines and safety compliance.

Operator Augmentation Systems

Operator augmentation systems in manual welding enhance precision and safety by integrating wearable sensors and real-time feedback devices, enabling welders to maintain control while reducing fatigue. In robotic welding, these systems complement automation by allowing operators to oversee multiple machines simultaneously, improving efficiency and minimizing errors through adaptive control algorithms.

Manual Welding vs Robotic Welding Infographic

industrydif.com

industrydif.com