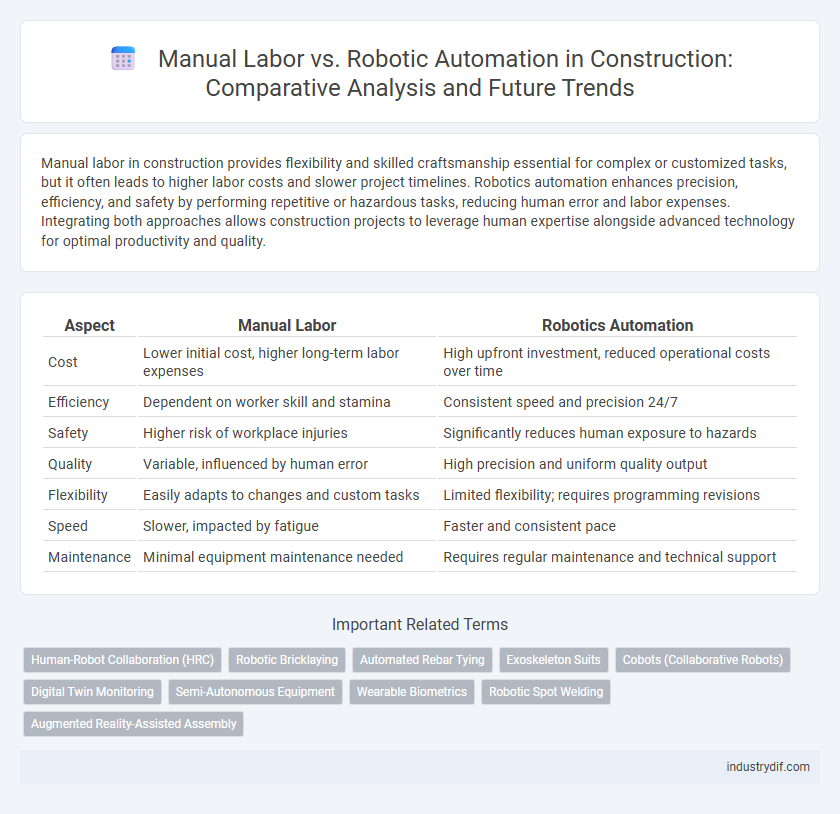

Manual labor in construction provides flexibility and skilled craftsmanship essential for complex or customized tasks, but it often leads to higher labor costs and slower project timelines. Robotics automation enhances precision, efficiency, and safety by performing repetitive or hazardous tasks, reducing human error and labor expenses. Integrating both approaches allows construction projects to leverage human expertise alongside advanced technology for optimal productivity and quality.

Table of Comparison

| Aspect | Manual Labor | Robotics Automation |

|---|---|---|

| Cost | Lower initial cost, higher long-term labor expenses | High upfront investment, reduced operational costs over time |

| Efficiency | Dependent on worker skill and stamina | Consistent speed and precision 24/7 |

| Safety | Higher risk of workplace injuries | Significantly reduces human exposure to hazards |

| Quality | Variable, influenced by human error | High precision and uniform quality output |

| Flexibility | Easily adapts to changes and custom tasks | Limited flexibility; requires programming revisions |

| Speed | Slower, impacted by fatigue | Faster and consistent pace |

| Maintenance | Minimal equipment maintenance needed | Requires regular maintenance and technical support |

Overview of Manual Labor in Construction

Manual labor in construction involves skilled and unskilled workers performing tasks such as bricklaying, carpentry, and concrete pouring, relying heavily on physical strength and craftsmanship. Despite advances in technology, manual labor remains essential for complex, precision-based projects and tasks in environments unsuitable for machinery. The workforce faces challenges including high injury rates and labor shortages, driving the industry's gradual integration of automation to enhance safety and efficiency.

Rise of Robotics Automation in Construction

Robotics automation in construction is rapidly transforming building processes by enhancing precision, efficiency, and safety while reducing labor costs and project timelines. Advanced robotic systems--including autonomous vehicles, bricklaying robots, and 3D printing machines--are increasingly utilized on construction sites to perform repetitive and hazardous tasks with consistent accuracy. The integration of robotics automation is driving a significant shift away from manual labor, enabling scalable production and addressing skilled labor shortages in the construction industry.

Key Differences: Manual Labor vs Robotics

Manual labor in construction relies on skilled workers performing tasks with hand tools and physical effort, offering flexibility and adaptability on-site. Robotics automation utilizes programmable machines to execute repetitive or hazardous tasks with high precision and efficiency, reducing human error and enhancing safety. Key differences include cost implications, speed of task completion, and the ability to scale operations, where robotics excels in repetitive processes while manual labor remains essential for complex, nuanced work.

Productivity and Efficiency Comparisons

Manual labor in construction often faces limitations in speed and consistency, leading to slower project completion and higher error rates. Robotics automation enhances productivity by performing repetitive tasks with precision and endurance, reducing downtime and material waste. Studies show that integrating robotics can boost efficiency by up to 40%, enabling faster timelines and improved overall quality in construction projects.

Impact on Construction Quality

Manual labor in construction allows for skilled craftsmanship and adaptability to complex tasks, but it can introduce variability in quality due to human error and fatigue. Robotics automation ensures consistent precision and repeatability in tasks like bricklaying and welding, significantly reducing defects and rework. The integration of robotics also enables real-time quality monitoring and data collection, enhancing overall construction standards.

Cost Analysis: Labor vs Robotics

Manual labor in construction typically incurs higher ongoing costs due to wages, benefits, and potential overtime payments. Robotics automation requires a significant upfront investment but reduces long-term expenses by lowering labor costs and minimizing errors, leading to increased project efficiency. Cost analysis reveals that while manual labor remains flexible for diverse tasks, robotics automation offers better scalability and consistent cost savings on large-scale projects.

Safety Considerations in Both Approaches

Manual labor in construction often involves higher risks of physical injuries such as falls, musculoskeletal disorders, and exposure to hazardous materials, necessitating rigorous safety protocols and personal protective equipment. Robotics automation reduces direct human exposure to dangerous tasks by utilizing machines for lifting, welding, and demolition, thereby lowering accident rates and enhancing overall site safety. However, robotics introduce new safety considerations including equipment malfunctions, programming errors, and the need for specialized operator training to prevent incidents.

Workforce Skills and Training Needs

Manual labor in construction demands skilled craftsmanship, practical problem-solving abilities, and on-site adaptability, requiring traditional vocational training and apprenticeships. Robotics automation emphasizes proficiency in programming, operating advanced machinery, and maintaining automated systems, necessitating specialized technical education and continuous upskilling in digital tools. The evolving construction industry increasingly integrates hybrid skill sets combining manual expertise with technological fluency to optimize productivity and safety.

Environmental Implications of Automation

Robotics automation in construction significantly reduces carbon emissions by minimizing heavy machinery idling and optimizing energy use, contrasting with manual labor's higher fuel consumption and waste production. Automated systems enhance precision, leading to less material waste and lower environmental impact through efficient resource management. Integrating robotics also decreases noise pollution and site disturbances, promoting a more sustainable construction environment.

Future Trends in Construction Labor

Future trends in construction labor highlight a significant shift towards robotics automation, driven by advances in AI, machine learning, and sensor technologies that enhance precision and efficiency on job sites. Manual labor remains essential for complex, adaptive tasks, but the integration of autonomous machinery and robotic systems is projected to reduce project timelines and labor costs. The construction industry is increasingly investing in collaborative robots (cobots) to support human workers, improving safety standards and productivity in the coming decade.

Related Important Terms

Human-Robot Collaboration (HRC)

Human-Robot Collaboration (HRC) in construction enhances productivity by combining the precision and endurance of robotics automation with the adaptability and problem-solving skills of manual labor. Integrating HRC systems reduces workplace injuries and project timelines while improving quality control and operational efficiency.

Robotic Bricklaying

Robotic bricklaying significantly increases construction efficiency by precisely placing thousands of bricks per day, reducing labor costs and minimizing human error. Advances in AI-driven robotics streamline repetitive tasks, enhance site safety, and accelerate project timelines compared to traditional manual labor methods.

Automated Rebar Tying

Automated rebar tying significantly enhances construction efficiency by reducing manual labor time by up to 70% and improving tie consistency, ultimately lowering injury risks associated with repetitive tasks. Robotics automation in rebar tying enables precise, faster installation, contributing to project cost savings and improved structural integrity in large-scale concrete construction.

Exoskeleton Suits

Exoskeleton suits enhance construction workers' strength and endurance by reducing physical strain and lowering injury risks during manual labor tasks such as lifting and repetitive movements. Integrating these wearable robotics improves productivity on job sites while maintaining workforce safety and ergonomics.

Cobots (Collaborative Robots)

Cobots in construction enhance manual labor efficiency by performing repetitive, hazardous tasks such as bricklaying and heavy lifting, reducing worker fatigue and injury risks. Integrating collaborative robots with skilled labor accelerates project timelines and improves precision, optimizing resource allocation on site.

Digital Twin Monitoring

Digital twin monitoring in construction enables real-time data visualization and predictive maintenance, enhancing robotics automation efficiency compared to manual labor. This technology reduces human error and downtime by providing continuous performance feedback and simulating project outcomes before physical execution.

Semi-Autonomous Equipment

Semi-autonomous equipment integrates manual labor efficiency with robotic precision, enhancing productivity and safety on construction sites. This technology reduces human error, lowers labor costs, and accelerates project timelines by automating repetitive tasks while allowing skilled operators to maintain control.

Wearable Biometrics

Wearable biometrics significantly enhance manual labor efficiency by continuously monitoring workers' vital signs, fatigue levels, and movement patterns, enabling real-time safety alerts and reducing injury risks on construction sites. Robotics automation complements this by integrating biometric data to optimize human-robot collaboration, improving precision and productivity while minimizing physical strain during complex tasks.

Robotic Spot Welding

Robotic spot welding significantly enhances construction efficiency by ensuring precise, consistent welds that reduce human error and increase structural integrity. Integrating automated welding systems lowers labor costs and accelerates project timelines, positioning robotics as a critical advancement over traditional manual labor in steel framework assembly.

Augmented Reality-Assisted Assembly

Augmented reality-assisted assembly in construction enhances manual labor by overlaying digital instructions and 3D models, improving accuracy and reducing errors during complex tasks. Robotics automation integrates AR technology to streamline workflows, increase efficiency, and facilitate real-time adjustments, bridging the gap between human expertise and machine precision.

Manual Labor vs Robotics Automation Infographic

industrydif.com

industrydif.com