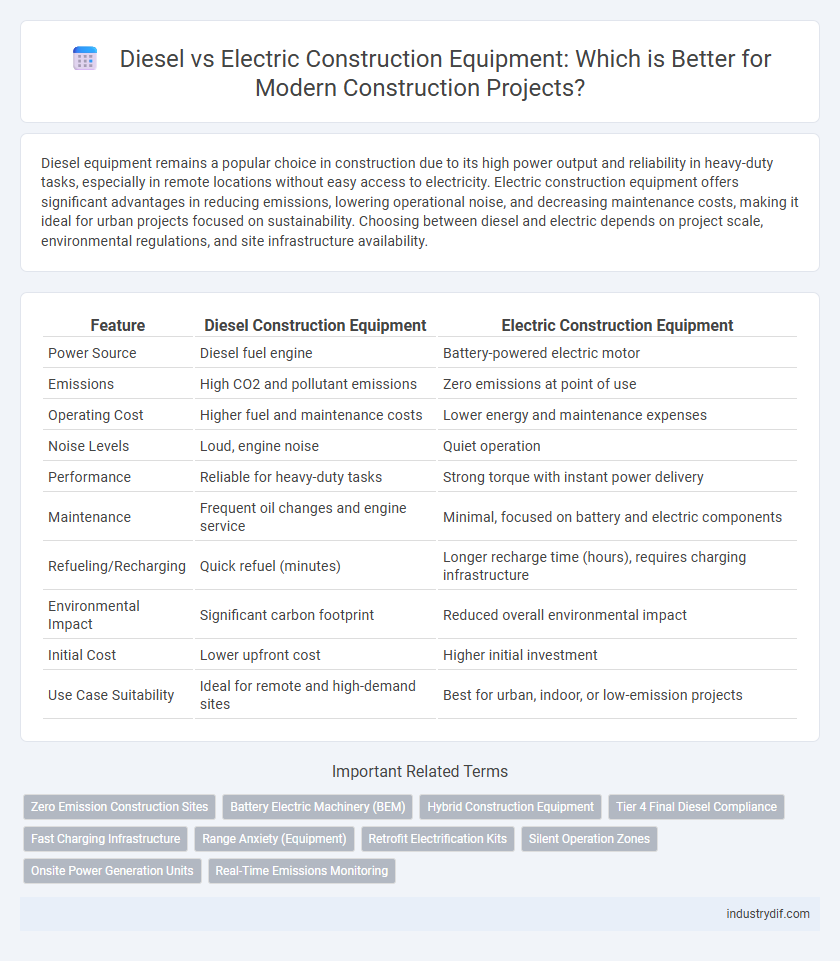

Diesel equipment remains a popular choice in construction due to its high power output and reliability in heavy-duty tasks, especially in remote locations without easy access to electricity. Electric construction equipment offers significant advantages in reducing emissions, lowering operational noise, and decreasing maintenance costs, making it ideal for urban projects focused on sustainability. Choosing between diesel and electric depends on project scale, environmental regulations, and site infrastructure availability.

Table of Comparison

| Feature | Diesel Construction Equipment | Electric Construction Equipment |

|---|---|---|

| Power Source | Diesel fuel engine | Battery-powered electric motor |

| Emissions | High CO2 and pollutant emissions | Zero emissions at point of use |

| Operating Cost | Higher fuel and maintenance costs | Lower energy and maintenance expenses |

| Noise Levels | Loud, engine noise | Quiet operation |

| Performance | Reliable for heavy-duty tasks | Strong torque with instant power delivery |

| Maintenance | Frequent oil changes and engine service | Minimal, focused on battery and electric components |

| Refueling/Recharging | Quick refuel (minutes) | Longer recharge time (hours), requires charging infrastructure |

| Environmental Impact | Significant carbon footprint | Reduced overall environmental impact |

| Initial Cost | Lower upfront cost | Higher initial investment |

| Use Case Suitability | Ideal for remote and high-demand sites | Best for urban, indoor, or low-emission projects |

Introduction to Diesel and Electric Construction Equipment

Diesel construction equipment operates using internal combustion engines fueled by diesel, providing high torque and durability essential for heavy-duty tasks such as excavation and hauling. Electric construction equipment utilizes battery-powered motors, offering lower emissions, reduced noise, and decreased operational costs suitable for urban or environmentally sensitive projects. Selecting between diesel and electric machinery depends on factors like site requirements, sustainability goals, and total cost of ownership.

Key Differences Between Diesel and Electric Machinery

Diesel construction equipment relies on internal combustion engines fueled by diesel, offering high power and extended operational time, making it ideal for heavy-duty tasks and remote sites without reliable electricity. Electric construction machinery operates on battery power or direct electric supply, producing zero emissions and lower noise levels, which enhances environmental sustainability and reduces onsite pollution. Key differences include fuel source, emissions output, maintenance costs, and operational efficiency, with electric machines excelling in eco-friendly performance and diesel models favored for raw power and refueling speed.

Energy Efficiency and Performance Comparison

Electric construction equipment offers significantly higher energy efficiency compared to diesel machinery, converting over 85% of electrical energy into mechanical power versus diesel engines' approximate 30-40% efficiency. Electric equipment delivers consistent torque and quieter operation, enhancing performance in urban and enclosed environments while reducing greenhouse gas emissions. Although diesel equipment provides longer run times and faster refueling, advancements in battery technology are rapidly closing the gap, making electric options increasingly viable for heavy-duty construction tasks.

Emissions and Environmental Impact

Diesel construction equipment emits significant amounts of nitrogen oxides (NOx) and particulate matter (PM), contributing to air pollution and greenhouse gas emissions. Electric construction equipment produces zero tailpipe emissions, significantly reducing the environmental footprint on construction sites. Transitioning to electric machinery supports compliance with stricter environmental regulations and promotes sustainable construction practices.

Initial Costs and Long-Term ROI

Diesel construction equipment typically requires higher initial investment compared to electric alternatives due to complex engine components and fuel systems. Electric construction equipment offers lower upfront costs and significantly reduced operating expenses through energy efficiency and minimal maintenance, enhancing long-term ROI. Despite the initial price gap, electric machinery's durability and energy savings often result in a more cost-effective solution over the equipment's operational lifespan.

Maintenance Requirements and Operating Lifespan

Diesel construction equipment typically requires more frequent maintenance due to engine oil changes, fuel system upkeep, and exhaust system repairs, while electric equipment benefits from fewer moving parts and reduced maintenance intervals. The operating lifespan of diesel machinery can be shorter because of engine wear and fuel contamination risks, whereas electric equipment often offers extended durability thanks to simpler drivetrains and fewer mechanical failures. Lifecycle cost analyses increasingly favor electric equipment due to lower maintenance costs and longer service intervals despite higher upfront investments.

Availability and Suitability for Various Job Sites

Diesel construction equipment offers widespread availability and robust performance, making it highly suitable for remote job sites lacking reliable electrical infrastructure. Electric construction equipment requires access to charging facilities but is ideal for urban or indoor environments due to zero emissions and reduced noise. Job site suitability depends on project location, duration, and environmental regulations impacting equipment choice between diesel and electric options.

Charging Infrastructure vs Fueling Logistics

Diesel construction equipment relies on established fueling logistics with widespread fuel stations enabling quick refueling and extended operation times critical for large job sites. Electric construction equipment demands a robust charging infrastructure, including high-capacity charging stations and grid support to minimize downtime and ensure continuous operation. Efficient energy management and the availability of fast chargers become strategic factors in determining the operational feasibility of electric machinery on construction projects.

Noise Levels and Worker Safety

Electric construction equipment produces significantly lower noise levels compared to diesel machinery, reducing occupational noise exposure and minimizing the risk of hearing loss among workers. Lower noise emissions enhance communication on-site, contributing to improved situational awareness and overall worker safety. Diesel equipment, while powerful, often exceeds acceptable noise thresholds, potentially increasing fatigue and stress-related hazards in construction environments.

Future Trends in Construction Equipment Technology

Electric construction equipment is rapidly advancing with improved battery life, faster charging technology, and lower operational emissions, positioning it as a sustainable alternative to traditional diesel equipment. Autonomous and smart IoT-integrated machinery enable real-time data analytics, predictive maintenance, and enhanced efficiency on job sites. Future trends indicate a hybrid shift toward electric-powered fleets complemented by AI-driven automation, reducing carbon footprints while boosting productivity in the construction industry.

Related Important Terms

Zero Emission Construction Sites

Electric construction equipment significantly reduces greenhouse gas emissions and air pollutants compared to diesel machinery, making it essential for achieving zero-emission construction sites. Advancements in battery technology and charging infrastructure have enhanced the performance and reliability of electric equipment, promoting sustainable construction practices worldwide.

Battery Electric Machinery (BEM)

Battery Electric Machinery (BEM) in construction offers significant reductions in greenhouse gas emissions and operational costs compared to traditional diesel equipment, enhancing sustainability and efficiency on job sites. Advances in battery technology provide longer runtimes and faster charging, making BEM a viable alternative that supports compliance with stricter environmental regulations.

Hybrid Construction Equipment

Hybrid construction equipment combines diesel and electric power sources to enhance fuel efficiency and reduce emissions on job sites. This technology leverages the high torque of diesel engines and the environmentally friendly advantages of electric motors, optimizing performance while lowering operating costs and meeting stricter environmental regulations.

Tier 4 Final Diesel Compliance

Tier 4 Final diesel equipment meets strict EPA emissions standards, reducing nitrogen oxides (NOx) and particulate matter (PM) significantly compared to previous diesel engines, making it a cleaner option in construction sites. Electric construction equipment offers zero on-site emissions and quieter operation, but Tier 4 Final diesel machines remain prevalent due to higher power density and longer operational range without frequent recharging.

Fast Charging Infrastructure

Fast charging infrastructure for electric construction equipment enables continuous operation by reducing downtime compared to diesel machines, which rely on fuel refueling but emit higher greenhouse gases. Advances in high-capacity chargers and battery technology enhance the efficiency of electric equipment, supporting sustainability goals and lower operational costs on job sites.

Range Anxiety (Equipment)

Diesel construction equipment offers extended operational hours and rapid refueling, mitigating range anxiety common with electric machinery limited by battery capacity and charging infrastructure. Electric equipment faces challenges in continuous heavy-duty tasks due to battery depletion, prompting advancements in high-density batteries and fast-charging solutions to bridge the operational range gap.

Retrofit Electrification Kits

Retrofit electrification kits transform traditional diesel construction equipment into electric-powered machinery, reducing emissions and operational costs while extending equipment lifecycle. These kits enable construction companies to comply with stricter environmental regulations and enhance sustainability without investing in entirely new electric equipment.

Silent Operation Zones

Electric construction equipment significantly reduces noise pollution, making it ideal for silent operation zones such as hospitals, schools, and residential areas. Diesel equipment, while powerful, generates higher noise levels and emissions, often violating regulations in noise-sensitive environments.

Onsite Power Generation Units

Diesel onsite power generation units dominate construction sites due to their high energy density and reliability in remote locations without grid access, providing robust power for heavy machinery and continuous operations. Electric onsite power units offer lower emissions and reduced noise, aligning with sustainable construction practices while benefiting from advancements in battery technology for improved efficiency and operational cost savings.

Real-Time Emissions Monitoring

Real-time emissions monitoring in diesel equipment reveals higher levels of nitrogen oxides (NOx) and particulate matter (PM) compared to electric construction equipment, which produces zero on-site emissions. This continuous data tracking enables construction managers to optimize equipment usage and comply with stringent environmental regulations while minimizing the project's carbon footprint.

Diesel Equipment vs Electric Construction Equipment Infographic

industrydif.com

industrydif.com