A physical walkthrough provides a tangible, on-site experience that allows stakeholders to observe real-time conditions and spatial relationships directly. Digital twins offer a dynamic, interactive 3D model that integrates real-time data for enhanced project monitoring, simulation, and predictive maintenance. Leveraging digital twins reduces the need for frequent physical visits, streamlines communication, and improves decision-making throughout construction phases.

Table of Comparison

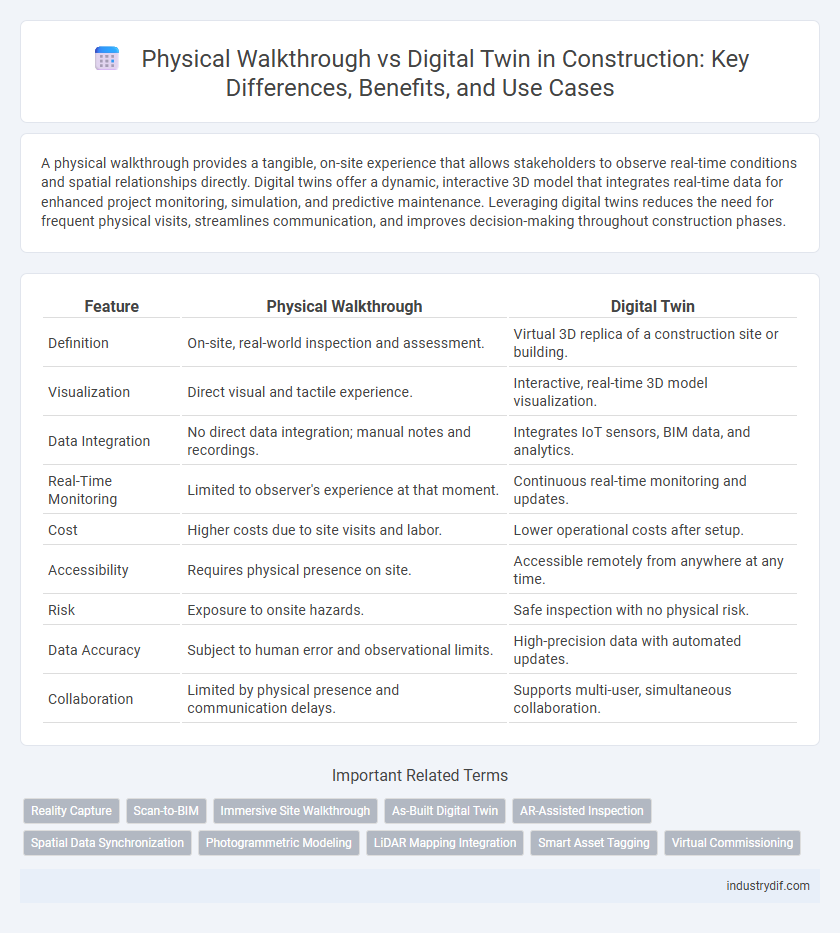

| Feature | Physical Walkthrough | Digital Twin |

|---|---|---|

| Definition | On-site, real-world inspection and assessment. | Virtual 3D replica of a construction site or building. |

| Visualization | Direct visual and tactile experience. | Interactive, real-time 3D model visualization. |

| Data Integration | No direct data integration; manual notes and recordings. | Integrates IoT sensors, BIM data, and analytics. |

| Real-Time Monitoring | Limited to observer's experience at that moment. | Continuous real-time monitoring and updates. |

| Cost | Higher costs due to site visits and labor. | Lower operational costs after setup. |

| Accessibility | Requires physical presence on site. | Accessible remotely from anywhere at any time. |

| Risk | Exposure to onsite hazards. | Safe inspection with no physical risk. |

| Data Accuracy | Subject to human error and observational limits. | High-precision data with automated updates. |

| Collaboration | Limited by physical presence and communication delays. | Supports multi-user, simultaneous collaboration. |

Introduction to Physical Walkthroughs and Digital Twins

Physical walkthroughs involve on-site inspections where project stakeholders directly observe construction progress, identify discrepancies, and assess quality in real time. Digital twins use advanced 3D modeling and IoT data to create virtual replicas of construction sites, enabling remote monitoring, predictive maintenance, and enhanced collaboration. Integrating physical walkthroughs with digital twins optimizes decision-making by combining tangible insights with precise, data-driven simulations.

Defining Physical Walkthroughs in Construction

Physical walkthroughs in construction involve on-site inspections where project managers, engineers, and stakeholders directly observe the construction process to assess progress, quality, and safety. These walkthroughs provide real-time, tactile feedback and enable immediate identification of issues such as structural discrepancies, material defects, or compliance violations. This method supports hands-on verification but may be limited by accessibility, time constraints, and the inability to simulate future scenarios compared to digital twin technology.

Understanding Digital Twin Technology

Digital Twin technology creates a real-time virtual replica of a physical construction site, enabling detailed monitoring and predictive analysis beyond what a physical walkthrough provides. It integrates IoT sensors, BIM data, and AI analytics to simulate construction progress, identify anomalies, and optimize resource allocation. This advanced digital approach enhances decision-making, reduces risks, and improves overall project efficiency compared to traditional inspection methods.

Key Differences Between Physical Walkthroughs and Digital Twins

Physical walkthroughs involve on-site inspections providing real-time tactile and visual feedback crucial for assessing construction progress and immediate problem-solving. Digital twins offer dynamic, data-rich 3D models enabling remote monitoring, predictive analytics, and integration with IoT sensors to optimize building performance and lifecycle management. While physical walkthroughs capture actual site conditions, digital twins deliver continuous virtual representations for enhanced decision-making and project efficiency.

Advantages of Physical Walkthroughs

Physical walkthroughs enable construction teams to directly observe site conditions, facilitating real-time identification of issues such as structural defects or safety hazards that may be overlooked in digital models. They provide tactile engagement with materials and spatial dimensions, enhancing communication among stakeholders and promoting more accurate decision-making during project phases. These walkthroughs foster immediate collaboration, leading to quicker resolutions and more effective coordination compared to purely virtual inspections.

Benefits of Digital Twin Adoption

Digital Twin technology in construction enables real-time monitoring and predictive maintenance, reducing downtime and enhancing project efficiency. It facilitates virtual simulations and scenario analysis, allowing stakeholders to identify potential issues before they arise on-site. This digital replication of physical assets supports better decision-making and optimizes resource allocation throughout the construction lifecycle.

Applications in Construction Project Management

Physical walkthroughs in construction project management provide real-time, on-site inspections for quality control and progress tracking, enabling immediate issue identification and resolution. Digital twins offer a virtual replica of the construction project, allowing for detailed simulations, predictive analytics, and remote monitoring to optimize scheduling, resource allocation, and risk management. Integrating both methods enhances decision-making accuracy, improves collaboration among stakeholders, and reduces costly delays by combining tangible site insights with advanced digital data analysis.

Challenges in Implementing Both Approaches

Physical walkthroughs face challenges such as limited accessibility to hazardous or confined areas and time-consuming manual inspections, which can lead to human errors and incomplete data capture. Digital twin implementation struggles with high initial costs, the need for advanced sensor integration, and ensuring real-time data accuracy for dynamic construction environments. Both approaches demand significant resource allocation and expertise to deliver reliable insights for effective project management and construction monitoring.

Impact on Collaboration and Communication

Physical walkthroughs provide real-time, immersive experience allowing on-site teams to directly observe construction progress, facilitating immediate feedback and hands-on problem solving. Digital twins enable continuous remote access to dynamic, data-rich models that enhance cross-disciplinary collaboration by synchronizing updates and visualizing project stages virtually. This integration improves communication efficiency by bridging geographical gaps and offering precise, up-to-date information to all stakeholders.

Future Trends in Construction Site Inspections

Future trends in construction site inspections emphasize the integration of physical walkthroughs with advanced digital twin technology to enhance accuracy and efficiency. Digital twins create real-time, interactive 3D models of construction sites, enabling remote inspections and predictive maintenance, which significantly reduce downtime and costs. Leveraging IoT sensors and AI analytics alongside traditional physical walkthroughs improves project monitoring and decision-making, shaping the evolution of construction site management.

Related Important Terms

Reality Capture

Physical walkthroughs provide direct site inspection but lack the precision and data richness of digital twins enhanced by reality capture technologies such as laser scanning and photogrammetry. Digital twins enable accurate 3D modeling and real-time monitoring, improving project management, clash detection, and progress tracking in construction.

Scan-to-BIM

Physical walkthroughs provide real-time, on-site inspection of construction progress, while Digital Twin technology leverages Scan-to-BIM processes to create precise, data-rich 3D models that enhance project visualization and coordination. Scan-to-BIM integrates high-resolution laser scanning or photogrammetry data into BIM platforms, enabling accurate as-built documentation and efficient clash detection without physical presence.

Immersive Site Walkthrough

Immersive site walkthroughs using digital twin technology offer a highly detailed, real-time visualization of construction sites, enabling stakeholders to identify potential issues and optimize workflows before physical work begins. Unlike traditional physical walkthroughs, digital twins integrate BIM data and IoT sensors to simulate site conditions dynamically, reducing risk and improving decision-making efficiency.

As-Built Digital Twin

As-built digital twins provide precise, real-time 3D models of constructed environments by integrating data from physical walkthroughs with BIM and IoT sensors, enhancing accuracy in project documentation and facility management. Unlike traditional physical walkthroughs, these digital representations streamline clash detection, progress monitoring, and predictive maintenance, optimizing construction workflows and lifecycle management.

AR-Assisted Inspection

AR-assisted inspection enhances physical walkthroughs by overlaying real-time digital twin data onto the construction site, enabling precise identification of discrepancies and faster issue resolution. Integrating AR with digital twins improves accuracy in quality control and reduces downtime by providing immersive, interactive visualization of building components during inspections.

Spatial Data Synchronization

Physical walkthroughs provide real-time spatial data through direct observation but lack continuous updates, while digital twins enable dynamic spatial data synchronization by integrating IoT sensors and BIM models for real-time, precise construction site monitoring. This synchronization enhances decision-making accuracy and project management efficiency by maintaining an up-to-date digital replica of physical environments.

Photogrammetric Modeling

Photogrammetric modeling enhances digital twin accuracy by generating high-resolution 3D representations from overlapping images, enabling precise virtual inspections that surpass traditional physical walkthrough limitations. This technology reduces on-site time and improves project monitoring by providing real-time, scalable visual data for construction progress and defect analysis.

LiDAR Mapping Integration

LiDAR mapping integration enhances physical walkthroughs by creating precise 3D models that capture site conditions in real time, enabling dynamic updates and accurate spatial analysis. Digital twins leverage this data to simulate construction processes, optimize project management, and reduce risks by providing a comprehensive virtual representation of the physical environment.

Smart Asset Tagging

Smart asset tagging enhances digital twin accuracy by providing real-time tracking data, outperforming traditional physical walkthroughs that rely on manual inspections prone to human error. Integrating smart tags into construction assets enables seamless updates within the digital twin model, improving project monitoring, maintenance, and lifecycle management.

Virtual Commissioning

Virtual commissioning leverages digital twins to simulate and validate construction system performance before physical deployment, reducing errors and project delays. Physical walkthroughs provide hands-on site verification but lack the predictive analytics and iterative testing capabilities of digital twin-based virtual commissioning.

Physical Walkthrough vs Digital Twin Infographic

industrydif.com

industrydif.com