Stick framing offers flexibility and cost-effectiveness for residential construction with traditional wood studs and onsite assembly, making it ideal for custom designs and smaller projects. Cross-laminated timber (CLT) provides superior structural strength, fire resistance, and sustainability due to its engineered layers, enabling faster assembly and larger spans in commercial or multi-story buildings. Choosing between stick framing and CLT depends on project scale, budget, and desired environmental impact for optimal performance and efficiency.

Table of Comparison

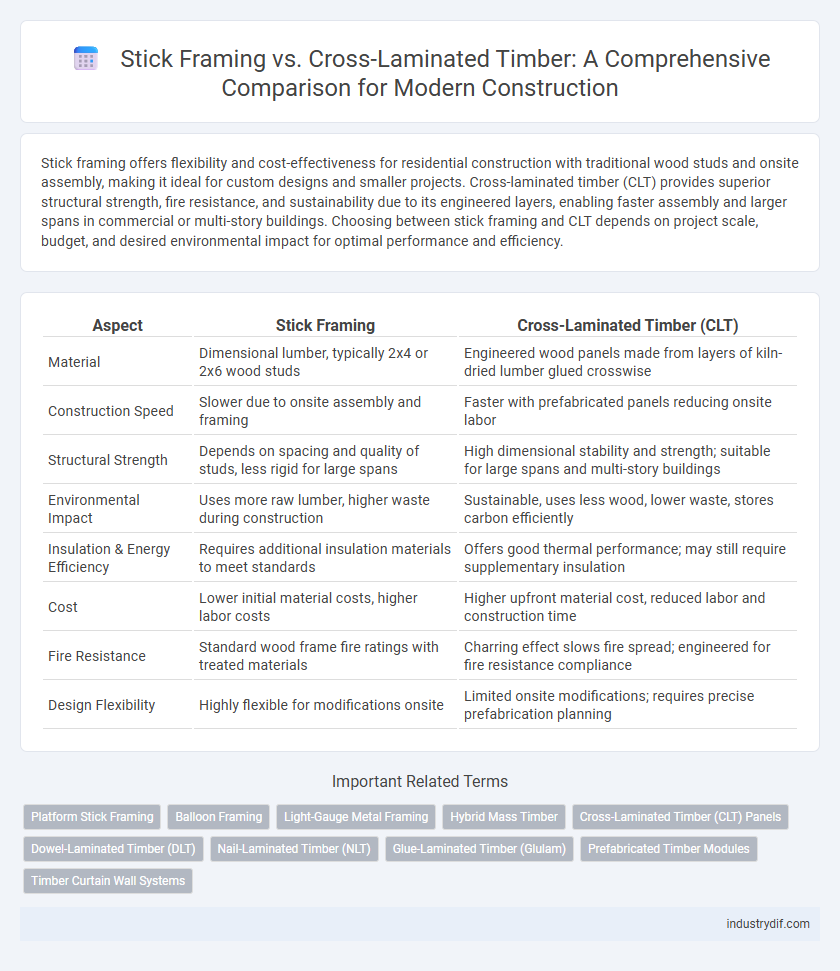

| Aspect | Stick Framing | Cross-Laminated Timber (CLT) |

|---|---|---|

| Material | Dimensional lumber, typically 2x4 or 2x6 wood studs | Engineered wood panels made from layers of kiln-dried lumber glued crosswise |

| Construction Speed | Slower due to onsite assembly and framing | Faster with prefabricated panels reducing onsite labor |

| Structural Strength | Depends on spacing and quality of studs, less rigid for large spans | High dimensional stability and strength; suitable for large spans and multi-story buildings |

| Environmental Impact | Uses more raw lumber, higher waste during construction | Sustainable, uses less wood, lower waste, stores carbon efficiently |

| Insulation & Energy Efficiency | Requires additional insulation materials to meet standards | Offers good thermal performance; may still require supplementary insulation |

| Cost | Lower initial material costs, higher labor costs | Higher upfront material cost, reduced labor and construction time |

| Fire Resistance | Standard wood frame fire ratings with treated materials | Charring effect slows fire spread; engineered for fire resistance compliance |

| Design Flexibility | Highly flexible for modifications onsite | Limited onsite modifications; requires precise prefabrication planning |

Overview of Stick Framing and Cross-Laminated Timber

Stick framing, a traditional construction method, uses dimensional lumber such as 2x4s or 2x6s assembled on site to create the building's skeleton, valued for its flexibility and cost-effectiveness. Cross-laminated timber (CLT) consists of engineered wood panels made by layering glued lumber boards in alternating directions, providing enhanced strength, stability, and sustainability. CLT panels offer faster assembly times and superior structural performance compared to stick framing, making them ideal for modern multi-story construction projects.

Historical Development of Construction Methods

Stick framing, originating in North America during the 17th century, revolutionized residential construction with its lightweight, flexible wood framework, allowing rapid building and adaptability. Cross-laminated timber (CLT), developed in the late 20th century in Europe, represents a modern evolution, utilizing engineered wood panels for enhanced strength, stability, and sustainability. The historical development from traditional stick framing to CLT highlights a shift towards industrialized, precision-engineered materials improving structural performance and environmental impact in construction.

Material Composition and Sustainability

Stick framing utilizes dimensional lumber such as 2x4 or 2x6 pieces made from solid wood, offering flexibility but generating more construction waste due to offcuts and on-site modifications. Cross-laminated timber (CLT) consists of multiple layers of kiln-dried lumber glued perpendicular to each other, providing superior structural strength and dimensional stability while maximizing wood efficiency. Sustainability advantages of CLT include reduced carbon footprint through mass timber manufacturing, faster assembly reducing site emissions, and enhanced energy efficiency from solid wood panels acting as natural insulators.

Structural Performance and Load-Bearing Capacity

Stick framing delivers reliable structural performance with widely used dimensional lumber, offering straightforward load distribution suitable for residential buildings. Cross-laminated timber (CLT) outperforms stick framing in load-bearing capacity due to its engineered layers, enhancing strength, rigidity, and resistance to lateral forces. CLT panels enable longer spans and increased seismic and wind resistance, making them ideal for multi-story and complex architectural constructions.

Speed and Efficiency of Construction

Stick framing offers faster on-site assembly due to its simpler, traditional techniques and readily available materials, which accelerates initial construction phases. Cross-laminated timber (CLT) significantly reduces overall build time by enabling large prefabricated panels to be quickly installed, minimizing on-site labor and weather delays. CLT's precision manufacturing and modular nature enhance efficiency, especially for complex or multi-story projects, outperforming stick framing in speed for large-scale developments.

Cost Comparison and Budget Considerations

Stick framing generally incurs lower upfront material costs due to the widespread availability of traditional lumber and established construction techniques, making it more budget-friendly for small to medium residential projects. Cross-laminated timber (CLT) requires higher initial investment because of its prefabrication process and specialized manufacturing, but it offers cost savings through faster erection times and reduced labor expenses on site. When budgeting, consider lifecycle costs where CLT's enhanced durability and energy efficiency can result in long-term financial benefits despite higher initial costs.

Design Flexibility and Architectural Applications

Stick framing offers high design flexibility, allowing custom adjustments on-site to accommodate complex architectural details and irregular shapes. Cross-laminated timber (CLT) provides superior structural stability and enables large-scale, open floor plans suited for modern architectural aesthetics. CLT panels also support faster assembly and can be prefabricated to exact specifications, making it ideal for innovative and sustainable design applications.

Fire Resistance and Safety Standards

Stick framing typically uses dimensional lumber that is more vulnerable to fire compared to cross-laminated timber (CLT), which char on the surface forming a protective layer that slows combustion. CLT panels meet stringent fire safety standards, often achieving fire-resistance ratings of up to 2 hours, making them suitable for multi-story construction under modern building codes. Fire resistance in stick framing largely depends on additional fireproofing treatments and drywall assemblies, which can add cost and complexity to meet similar safety criteria.

Environmental Impact and Carbon Footprint

Stick framing generates more waste due to on-site cutting and uses lumber with higher embodied carbon compared to cross-laminated timber (CLT). CLT panels are manufactured in controlled facilities, optimizing material use and resulting in a lower carbon footprint through carbon sequestration within the wood layers. Choosing CLT contributes significantly to reducing greenhouse gas emissions in construction by storing carbon and minimizing construction waste.

Future Trends in Timber Construction Technologies

Emerging trends in timber construction highlight a shift from traditional stick framing to innovative cross-laminated timber (CLT) systems, driven by CLT's enhanced structural strength, sustainability, and prefabrication efficiency. Advanced digital fabrication techniques and building information modeling (BIM) integration are accelerating the adoption of CLT, enabling precision construction and reduced material waste. The future of timber construction leverages engineered wood products like CLT to meet growing demands for eco-friendly, high-performance building solutions in urban development.

Related Important Terms

Platform Stick Framing

Platform stick framing utilizes dimensional lumber to create a stable, level platform for each floor, enabling faster construction and easier customization compared to cross-laminated timber (CLT), which offers superior structural strength and fire resistance but requires specialized equipment and expertise. This method is widely preferred in residential construction for its cost-effectiveness and adaptability to various design changes during the building process.

Balloon Framing

Balloon framing, a traditional stick framing method, uses long, continuous studs extending from the foundation to the roof, offering superior vertical load distribution but posing fire safety challenges compared to cross-laminated timber (CLT). CLT provides prefabricated, dimensional stability and enhanced fire resistance, while balloon framing's continuous studs demand precise craftsmanship to prevent air and moisture infiltration.

Light-Gauge Metal Framing

Light-gauge metal framing offers superior durability and resistance to moisture, fire, and pests compared to traditional stick framing, making it a preferred choice for modern construction projects seeking longevity and minimal maintenance. When contrasted with cross-laminated timber (CLT), light-gauge metal framing provides greater design flexibility and faster installation while still supporting sustainable building practices due to its recyclability and reduced waste generation.

Hybrid Mass Timber

Hybrid mass timber construction combines stick framing with cross-laminated timber (CLT) panels to optimize structural performance, offering enhanced load-bearing capacity and reduced construction time. This approach leverages the dimensional stability and sustainability of CLT alongside the flexibility and cost-effectiveness of traditional stick framing, making it ideal for mid-rise buildings.

Cross-Laminated Timber (CLT) Panels

Cross-Laminated Timber (CLT) panels offer superior structural strength and dimensional stability compared to traditional stick framing, enabling faster assembly and reduced waste on construction sites. Engineered from layers of kiln-dried lumber glued perpendicularly, CLT panels provide enhanced fire resistance, thermal insulation, and sustainability through renewable materials certification.

Dowel-Laminated Timber (DLT)

Dowel-Laminated Timber (DLT) offers a sustainable alternative to traditional stick framing by utilizing hardwood dowels for fastening, eliminating the need for metal connectors and adhesives common in Cross-Laminated Timber (CLT). This innovative mass timber product combines the benefits of rapid on-site assembly, dimensional stability, and enhanced seismic performance, making it a cost-effective choice for residential and commercial construction projects.

Nail-Laminated Timber (NLT)

Nail-Laminated Timber (NLT) offers superior dimensional stability and faster on-site assembly compared to traditional stick framing due to its prefabricated layers of solid-sawn lumber mechanically fastened with nails. Unlike Cross-Laminated Timber (CLT), NLT provides enhanced flexibility in design modifications and is typically more cost-effective for mid-rise construction projects.

Glue-Laminated Timber (Glulam)

Glue-Laminated Timber (Glulam) offers superior strength and design flexibility compared to traditional stick framing by bonding multiple layers of dimensional lumber with durable adhesives, enabling longer spans and complex shapes. Unlike Cross-Laminated Timber (CLT), which provides large, flat panels for flooring and walls, Glulam is primarily used for beams and structural supports, making it ideal for architectural applications requiring both aesthetics and load-bearing capacity.

Prefabricated Timber Modules

Prefabricated timber modules in cross-laminated timber (CLT) construction offer superior dimensional stability, faster assembly times, and enhanced structural strength compared to traditional stick framing, which relies on individual studs and joists assembled on-site. CLT panels, engineered for precision manufacturing, reduce material waste and improve insulation performance, making them a sustainable and efficient choice for modern construction projects.

Timber Curtain Wall Systems

Timber curtain wall systems utilizing cross-laminated timber (CLT) offer enhanced structural stability and superior thermal insulation compared to traditional stick framing, which relies on individual dimensional lumber components. The prefabricated nature of CLT panels enables faster installation and improved airtightness, reducing construction time and energy costs while maintaining aesthetic flexibility in modern architectural designs.

Stick Framing vs Cross-Laminated Timber Infographic

industrydif.com

industrydif.com