Formwork provides a temporary mold to shape concrete structures, requiring manual assembly and disassembly for each section. Climbing formwork, a specialized type, moves vertically with the structure, enabling continuous pouring of concrete in high-rise construction. This method significantly enhances efficiency and safety by reducing repetitive setup time and minimizing labor-intensive tasks.

Table of Comparison

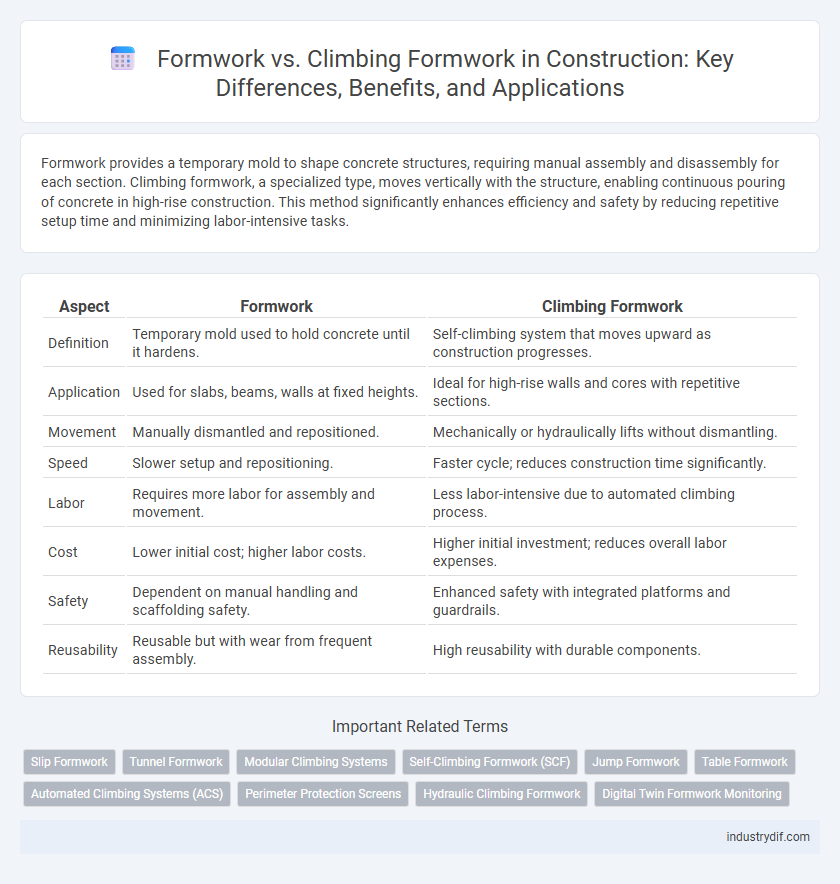

| Aspect | Formwork | Climbing Formwork |

|---|---|---|

| Definition | Temporary mold used to hold concrete until it hardens. | Self-climbing system that moves upward as construction progresses. |

| Application | Used for slabs, beams, walls at fixed heights. | Ideal for high-rise walls and cores with repetitive sections. |

| Movement | Manually dismantled and repositioned. | Mechanically or hydraulically lifts without dismantling. |

| Speed | Slower setup and repositioning. | Faster cycle; reduces construction time significantly. |

| Labor | Requires more labor for assembly and movement. | Less labor-intensive due to automated climbing process. |

| Cost | Lower initial cost; higher labor costs. | Higher initial investment; reduces overall labor expenses. |

| Safety | Dependent on manual handling and scaffolding safety. | Enhanced safety with integrated platforms and guardrails. |

| Reusability | Reusable but with wear from frequent assembly. | High reusability with durable components. |

Understanding Formwork in Construction

Formwork in construction refers to temporary or permanent molds used to shape and support concrete until it hardens, playing a crucial role in defining structural dimensions and surface finishes. Climbing formwork is a specialized type designed to move vertically as the building progresses, ideal for high-rise structures where continuous vertical construction is required. Understanding the differences between traditional formwork and climbing formwork helps optimize construction efficiency, safety, and project timelines.

Defining Climbing Formwork Systems

Climbing formwork systems are specialized formwork used for constructing tall structures such as high-rise buildings and towers, allowing the formwork to be raised vertically without dismantling. These systems improve efficiency by enabling continuous concrete pouring and reducing labor costs compared to traditional stationary formwork. Climbing formwork mechanisms typically include hydraulic jacks or climbing anchors that secure the formwork to the structure as it progresses upward.

Key Differences: Traditional Formwork vs Climbing Formwork

Traditional formwork involves the assembly of reusable panels or molds to shape concrete at ground level before repositioning for successive pours, while climbing formwork is a specialized system that ascends vertically along the structure, enabling continuous, efficient construction of tall walls and cores. Climbing formwork minimizes manual labor and improves safety by using hydraulic jacks or cranes for elevation, significantly reducing the cycle time between concrete pours compared to traditional methods. Key differences include the climbing system's ability to maintain alignment during lifting and its adaptability to complex geometries, making it ideal for skyscrapers and high-rise structures.

Applications of Standard Formwork

Standard formwork is primarily used in horizontal concrete structures such as slabs, beams, and foundations due to its ease of assembly and flexibility. It supports repetitive casting workflows in projects like residential buildings, commercial complexes, and infrastructure where vertical height changes are minimal. This system allows efficient shaping, alignment, and load transfer for diverse construction applications requiring stable and reusable molds.

Advantages of Climbing Formwork

Climbing formwork offers significant advantages in high-rise construction by enabling continuous, efficient casting of concrete walls without the need for extensive dismantling and repositioning, thereby reducing labor time and costs. Its self-climbing mechanism allows for safe and rapid vertical movement using hydraulic jacks or cranes, enhancing productivity on tall structures like towers and bridges. The reuse potential of climbing formwork systems contributes to sustainability and cost-effectiveness through multiple project cycles, outperforming traditional fixed formwork in speed and operational efficiency.

Structural Suitability: When to Use Each System

Formwork is structurally suitable for straightforward, repetitive concrete elements such as slabs, beams, and columns in low to mid-rise buildings, offering flexibility and ease of assembly. Climbing formwork excels in high-rise construction and complex vertical structures, providing continuous structural support as it ascends and reducing cycle times for tall walls and cores. Selecting the appropriate system depends on project height, complexity, and load-bearing requirements, ensuring safety and efficiency during concrete placement.

Material Options in Formwork Solutions

Formwork solutions in construction primarily utilize materials such as timber, steel, aluminum, and plastic composites, each offering distinct advantages in durability, weight, and cost. Climbing formwork systems often incorporate lightweight aluminum or steel frameworks to ensure ease of vertical movement and structural integrity during high-rise construction. Selecting the appropriate material depends on project scale, repeat usage requirements, and environmental conditions to optimize efficiency and safety.

Cost Comparison: Investment and Efficiency

Formwork systems involve significant initial investment but offer versatility across diverse construction projects, whereas climbing formwork demands higher upfront costs due to specialized equipment yet enhances efficiency through rapid reuse and continuous vertical progression. Climbing formwork reduces labor costs and cycle times by minimizing dismantling and repositioning delays, improving overall project timelines despite its steeper capital expenditure. Cost-effectiveness balances on project scale and complexity, with climbing formwork favored in high-rise or repetitive pours, while traditional formwork suits smaller or varied structural elements.

Safety Considerations for Formwork Systems

Formwork systems require rigorous safety measures to prevent structural failures and ensure worker protection during concrete pouring and curing. Climbing formwork, designed for vertical progression on high-rise projects, necessitates secure anchoring, regular inspection, and fall protection due to increased height risks. Proper training and adherence to engineering specifications are critical in both traditional and climbing formwork to minimize hazards and guarantee structural integrity.

Innovations and Trends in Formwork Technology

Innovations in formwork technology emphasize lightweight, modular materials and automated systems that increase efficiency and safety on construction sites. Climbing formwork integrates automation and hydraulic systems to enable rapid vertical movement, reducing labor costs and construction time for high-rise structures. Emerging trends prioritize sustainability through reusable components and digital integration for real-time monitoring and precise alignment during concrete curing.

Related Important Terms

Slip Formwork

Slip formwork offers continuous concrete pouring by moving the formwork gradually upward, enabling efficient construction of tall structures like silos, chimneys, and high-rise cores. Unlike climbing formwork, which requires periodic lifting and setting, slip formwork provides a faster, more cost-effective method with enhanced structural uniformity and reduced labor intensity.

Tunnel Formwork

Tunnel formwork offers a specialized solution for fast, repetitive concrete casting in tunnel construction, enabling simultaneous forming of walls and slabs with high precision. Unlike climbing formwork, which incrementally rises with the structure, tunnel formwork accelerates construction cycles by allowing large sections to be cast as a single unit.

Modular Climbing Systems

Modular climbing systems offer enhanced efficiency in construction by enabling the reuse of formwork components across multiple levels, reducing labor and material costs compared to traditional formwork. These systems provide adaptable, safe, and time-saving solutions for high-rise structures, facilitating continuous vertical progression without the need for dismantling after each pour.

Self-Climbing Formwork (SCF)

Self-Climbing Formwork (SCF) enhances construction efficiency by automatically elevating without external cranes, enabling continuous concrete pouring for high-rise structures. This advanced system minimizes labor costs, improves safety, and accelerates project timelines compared to traditional hanging or manually climbed formwork methods.

Jump Formwork

Jump formwork, also known as climbing formwork, is a highly efficient system used in the construction of tall structures like high-rise buildings and towers, enabling continuous concrete pouring without dismantling the formwork at each level. Unlike traditional fixed formwork, jump formwork automates vertical movement through hydraulic jacks or cranes, significantly reducing labor costs and construction time.

Table Formwork

Table formwork offers a pre-assembled, modular solution that accelerates slab casting by allowing rapid repositioning and reuse across repetitive floor cycles. Unlike climbing formwork, which climbs with the structure to shape vertical elements, table formwork specializes in horizontal surfaces, maximizing efficiency in large floor slab construction.

Automated Climbing Systems (ACS)

Automated Climbing Systems (ACS) in formwork enhance construction efficiency by enabling continuous vertical movement without dismantling, reducing labor and time costs compared to traditional formwork methods. These ACS units integrate hydraulic jacks and synchronized controls for precise positioning, improving safety and structural quality in high-rise and complex concrete projects.

Perimeter Protection Screens

Perimeter protection screens in formwork systems provide essential safety by preventing debris and workers from falling, with traditional formwork relying on fixed scaffolding barriers while climbing formwork integrates adjustable mesh screens that rise incrementally with the structure. Climbing formwork screens enhance efficiency and site safety by offering continuous, adaptable protection tailored to high-rise construction projects.

Hydraulic Climbing Formwork

Hydraulic climbing formwork offers superior efficiency in high-rise construction by providing automated vertical movement and enhanced safety compared to traditional timber or metal formwork systems. This advanced formwork system reduces labor costs and cycle times while ensuring precise alignment and stability during concrete pouring processes.

Digital Twin Formwork Monitoring

Digital Twin Formwork Monitoring enhances both traditional and climbing formwork systems by providing real-time data on structural integrity, load distribution, and curing progress, enabling proactive adjustments to improve safety and efficiency. Integrating IoT sensors and 3D modeling within formwork digital twins accelerates decision-making and reduces construction delays through precise performance analytics.

Formwork vs Climbing Formwork Infographic

industrydif.com

industrydif.com