Prefabrication involves manufacturing building components off-site and assembling them on-site, offering precise quality control and reduced construction time. Modular construction takes prefabrication further by producing fully finished modules in a factory, which are then transported and installed at the site, accelerating project completion significantly. Both methods enhance efficiency and sustainability, but modular construction provides greater flexibility in design and scalability for complex projects.

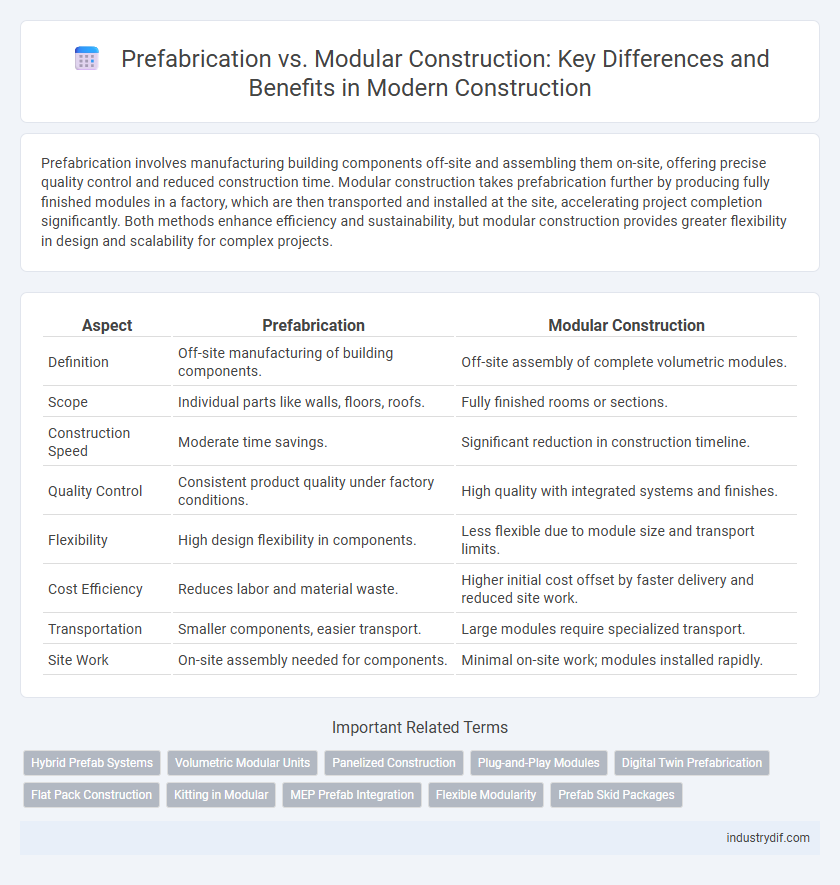

Table of Comparison

| Aspect | Prefabrication | Modular Construction |

|---|---|---|

| Definition | Off-site manufacturing of building components. | Off-site assembly of complete volumetric modules. |

| Scope | Individual parts like walls, floors, roofs. | Fully finished rooms or sections. |

| Construction Speed | Moderate time savings. | Significant reduction in construction timeline. |

| Quality Control | Consistent product quality under factory conditions. | High quality with integrated systems and finishes. |

| Flexibility | High design flexibility in components. | Less flexible due to module size and transport limits. |

| Cost Efficiency | Reduces labor and material waste. | Higher initial cost offset by faster delivery and reduced site work. |

| Transportation | Smaller components, easier transport. | Large modules require specialized transport. |

| Site Work | On-site assembly needed for components. | Minimal on-site work; modules installed rapidly. |

Understanding Prefabrication in Construction

Prefabrication in construction involves manufacturing building components off-site in a controlled factory environment to enhance precision and reduce on-site labor. This method improves project timelines by allowing simultaneous site preparation and component fabrication, leading to faster overall construction. Quality control and material efficiency are significantly improved through standardized production processes inherent in prefabrication.

What Is Modular Construction?

Modular construction involves manufacturing building sections, or modules, in a controlled factory environment before transporting them to the site for assembly. This method enhances efficiency by minimizing on-site labor and reducing construction time compared to traditional building techniques. It allows for precise quality control, scalability, and flexibility in design, making it ideal for residential, commercial, and institutional projects.

Key Differences Between Prefabrication and Modular Construction

Prefabrication involves manufacturing building components off-site and transporting them for on-site assembly, while modular construction assembles entire sections or modules off-site, creating nearly complete units before delivery. Key differences include the scale of off-site work, with prefabrication focusing on individual parts like walls or panels, and modular construction producing fully integrated modules such as rooms or entire floors. Modular construction typically reduces on-site labor and construction time more significantly compared to prefabrication due to the higher level of completion prior to installation.

Advantages of Prefabrication Techniques

Prefabrication techniques in construction significantly enhance project efficiency by enabling off-site manufacturing of components, which reduces on-site labor requirements and minimizes weather-related delays. This method improves quality control through factory conditions, ensuring consistent standards and reducing material waste. Prefabrication also accelerates construction schedules, lowers overall costs, and increases safety by limiting hazardous on-site activities.

Benefits of Modular Construction Solutions

Modular construction offers significant benefits including faster project completion times due to off-site fabrication and simultaneous site preparation, reducing overall construction schedules by up to 50%. Enhanced quality control is achieved through factory-based manufacturing environments, which minimize weather-related delays and material waste. This method also provides greater design flexibility and improved sustainability by enabling precise resource management and reducing site disruption.

Applications of Prefabrication in Modern Construction

Prefabrication in modern construction is widely applied in residential housing, commercial buildings, and infrastructure projects such as bridges and schools. This technique allows for precise quality control and faster project completion due to off-site manufacturing of components like walls, floors, and roof panels. Prefabricated elements are especially effective in urban developments and large-scale housing projects, reducing on-site labor and minimizing material waste.

Use Cases for Modular Construction in the Industry

Modular construction is extensively utilized in sectors requiring rapid project delivery and reduced onsite labor, such as residential housing, healthcare facilities, and educational buildings. Its prefabricated modules enable consistent quality control, streamlined installation, and minimized site disruption, proving ideal for urban infill projects and disaster relief housing. The adaptability of modular construction supports scalable solutions for office developments and hospitality structures, optimizing both time and cost efficiency in complex project environments.

Cost Comparison: Prefabrication vs Modular Construction

Prefabrication generally reduces labor costs by assembling components off-site in controlled environments, leading to less waste and faster on-site installation. Modular construction, while involving higher upfront investment for factory-built modules, often results in significant savings through reduced construction timelines and improved quality control, minimizing costly delays. Both methods offer cost efficiency compared to traditional construction, but prefab excels in component-level savings, whereas modular construction delivers value through comprehensive project acceleration and integration.

Challenges and Limitations of Each Method

Prefabrication faces challenges such as transportation constraints and limited customization due to factory-based production, which can delay project timelines when onsite adjustments are necessary. Modular construction often encounters logistical issues with large module transportation and requires precise coordination between manufacturing and onsite assembly to prevent misalignment or damage. Both methods demand significant upfront planning and higher initial costs, which can be limiting factors for small-scale or highly customized projects.

Future Trends in Prefabrication and Modular Construction

Future trends in prefabrication and modular construction highlight increased adoption of digital technologies such as Building Information Modeling (BIM) and automation to enhance precision and reduce construction timelines. Sustainable materials and energy-efficient designs are being integrated into modular units to meet growing environmental regulations and green building certifications. The rise of smart factories and off-site manufacturing is expected to drive cost savings, scalability, and higher quality standards in construction projects worldwide.

Related Important Terms

Hybrid Prefab Systems

Hybrid prefab systems combine the precision of factory-built modular components with on-site traditional construction, optimizing project timelines and reducing material waste. This integration enhances structural quality and design flexibility while maintaining cost efficiency in complex construction projects.

Volumetric Modular Units

Volumetric modular units, a key element in modular construction, offer fully finished, three-dimensional sections built off-site, significantly reducing on-site labor and construction time compared to traditional prefabrication methods that primarily involve flat components. These volumetric units enhance quality control through factory settings and enable faster project delivery by allowing simultaneous site preparation and building fabrication.

Panelized Construction

Panelized construction delivers precise off-site fabrication of wall, floor, and roof panels, accelerating on-site assembly and reducing labor costs compared to traditional building methods. This approach enhances quality control through factory conditions and minimizes material waste, standing out as a cost-effective alternative within the broader scope of prefabrication and modular construction techniques.

Plug-and-Play Modules

Plug-and-play modules in modular construction streamline onsite assembly by delivering pre-engineered, factory-built components that ensure precise fit and faster installation compared to traditional prefabrication methods. This approach reduces labor costs, minimizes construction waste, and accelerates project timelines through standardized, easily integrated units.

Digital Twin Prefabrication

Digital twin prefabrication integrates real-time data and virtual models to enhance precision and efficiency in modular construction, reducing errors and accelerating project timelines. This technology enables virtual testing of prefab components, optimizing assembly processes and ensuring seamless integration on-site.

Flat Pack Construction

Flat pack construction, a subset of modular construction, involves manufacturing components in a factory and shipping them in flat-packed form for on-site assembly, reducing transportation costs and construction time. This method enhances precision, minimizes waste, and allows for scalable, efficient production compared to traditional prefabrication techniques that often require larger, pre-assembled sections.

Kitting in Modular

Kitting in modular construction streamlines the assembly process by pre-assembling and organizing materials and components into specific kits tailored for each module, reducing on-site labor and minimizing errors. This approach enhances efficiency and quality control compared to traditional prefabrication methods where components are produced separately without integrated packaging or workflow coordination.

MEP Prefab Integration

MEP prefab integration in modular construction streamlines mechanical, electrical, and plumbing systems by assembling components off-site in controlled environments, enhancing precision and reducing on-site labor compared to traditional prefabrication. This approach minimizes installation errors, accelerates project timelines, and improves overall quality by enabling simultaneous MEP system fabrication alongside structural modules.

Flexible Modularity

Flexible modularity in prefabrication allows for customizable building components that can be easily reconfigured or expanded to suit changing project requirements, enhancing adaptability in construction design. This approach reduces on-site labor and waste while accelerating construction timelines by integrating standardized modules with scalable flexibility.

Prefab Skid Packages

Prefab skid packages offer streamlined assembly and transport efficiencies by integrating multiple components into a single, factory-built unit, reducing onsite labor and installation time. These packages enhance project timelines and quality control compared to traditional modular construction by enabling precise fabrication under controlled conditions.

Prefabrication vs Modular Construction Infographic

industrydif.com

industrydif.com