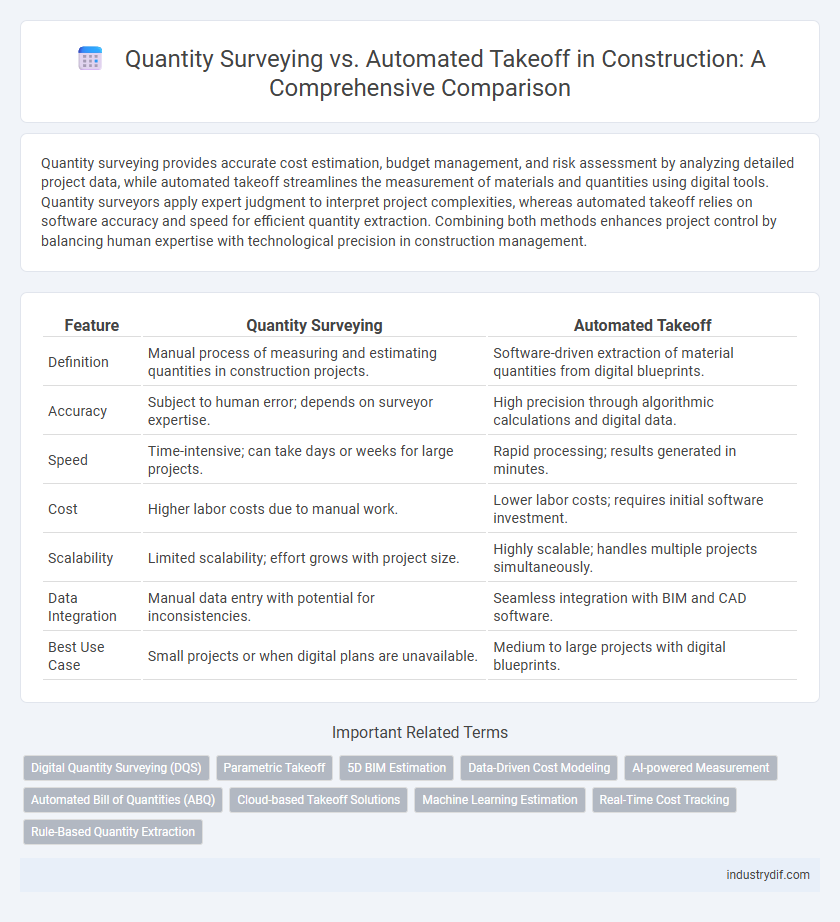

Quantity surveying provides accurate cost estimation, budget management, and risk assessment by analyzing detailed project data, while automated takeoff streamlines the measurement of materials and quantities using digital tools. Quantity surveyors apply expert judgment to interpret project complexities, whereas automated takeoff relies on software accuracy and speed for efficient quantity extraction. Combining both methods enhances project control by balancing human expertise with technological precision in construction management.

Table of Comparison

| Feature | Quantity Surveying | Automated Takeoff |

|---|---|---|

| Definition | Manual process of measuring and estimating quantities in construction projects. | Software-driven extraction of material quantities from digital blueprints. |

| Accuracy | Subject to human error; depends on surveyor expertise. | High precision through algorithmic calculations and digital data. |

| Speed | Time-intensive; can take days or weeks for large projects. | Rapid processing; results generated in minutes. |

| Cost | Higher labor costs due to manual work. | Lower labor costs; requires initial software investment. |

| Scalability | Limited scalability; effort grows with project size. | Highly scalable; handles multiple projects simultaneously. |

| Data Integration | Manual data entry with potential for inconsistencies. | Seamless integration with BIM and CAD software. |

| Best Use Case | Small projects or when digital plans are unavailable. | Medium to large projects with digital blueprints. |

Introduction to Quantity Surveying and Automated Takeoff

Quantity surveying involves detailed cost estimation, contract management, and budget control in construction projects, ensuring accurate financial planning and resource allocation. Automated takeoff uses software to quickly quantify materials and labor requirements from digital blueprints, increasing efficiency and reducing human error. Both processes support project cost management but automated takeoff streamlines data extraction while quantity surveying provides comprehensive financial oversight.

Core Functions of Quantity Surveyors

Quantity surveyors specialize in cost estimation, contract management, and risk assessment during construction projects, ensuring budgets align with project scopes. Their expertise includes preparing detailed bills of quantities and managing procurement processes to optimize resource allocation. Automated takeoff tools streamline material measurement but cannot fully replace the strategic financial oversight and contractual expertise provided by quantity surveyors.

What is Automated Takeoff?

Automated takeoff utilizes advanced software to extract quantities and measurements directly from digital construction plans, streamlining the estimation process in quantity surveying. This technology reduces human error and accelerates project bidding by quickly generating precise material and labor requirements. Integrating automated takeoff tools improves accuracy and efficiency in cost planning and resource management within construction projects.

Manual vs Digital Takeoff Processes

Quantity surveying relies on manual takeoff processes involving detailed measurement and cost estimation from physical blueprints, which can be time-consuming and prone to human error. Automated takeoff processes utilize advanced software to digitally extract quantities and costs from BIM models or digital plans, increasing accuracy and efficiency. Digital takeoff tools enhance productivity by reducing manual data entry, minimizing mistakes, and enabling real-time updates in construction project management.

Accuracy Comparison: Quantity Surveying vs Automated Takeoff

Quantity surveying relies on expert analysis and manual measurements to ensure accuracy in construction cost estimation, but it is prone to human errors and time-consuming revision processes. Automated takeoff uses advanced software and digital blueprints to deliver precise material quantity calculations rapidly, significantly reducing errors caused by manual data entry. Studies show automated takeoff systems can improve accuracy by up to 30% compared to traditional quantity surveying methods, enhancing overall project efficiency and cost control.

Cost Implications in Both Methods

Quantity surveying involves detailed manual measurements and cost estimations, often resulting in higher labor expenses and longer project timelines. Automated takeoff utilizes software tools to rapidly quantify materials and costs, reducing labor costs but requiring upfront investment in technology and training. Both methods impact overall construction budgeting, with quantity surveying favoring accuracy and risk mitigation while automated takeoff enhances efficiency and quick cost assessment.

Time Efficiency and Project Timelines

Quantity surveying relies heavily on manual measurements and detailed cost analysis, which can extend project timelines due to the time-intensive nature of data collection and verification. Automated takeoff software significantly enhances time efficiency by rapidly extracting accurate material quantities from digital plans, reducing human error and accelerating the estimation process. Integrating automated takeoff with quantity surveying optimizes project schedules by enabling quicker decision-making and more precise resource allocation throughout the construction lifecycle.

Impact on Project Collaboration

Quantity surveying enhances project collaboration by providing detailed cost analysis and budget management through expert human insight, promoting clear communication among stakeholders. Automated takeoff streamlines the measurement process with precision and speed, enabling real-time data sharing that improves coordination between design and construction teams. Integrating quantity surveying with automated takeoff tools fosters a collaborative environment that reduces errors, accelerates decision-making, and optimizes resource allocation.

Skills and Technology Requirements

Quantity surveying demands strong analytical skills, cost estimation expertise, and proficiency in traditional measurement methods, while automated takeoff relies heavily on advanced software proficiency, digital measurement tools, and data integration capabilities. Mastery of construction drawings, material specifications, and contract knowledge is essential for quantity surveyors, whereas automated takeoff specialists prioritize skills in BIM (Building Information Modeling), CAD software, and automated data extraction. Both fields require a blend of technical knowledge and attention to detail, but automated takeoff emphasizes technological adaptability and software fluency for efficiency and accuracy.

Future Trends in Construction Cost Estimation

Future trends in construction cost estimation emphasize the integration of automated takeoff technologies with advanced quantity surveying practices to enhance accuracy and efficiency. Machine learning algorithms and BIM (Building Information Modeling) interoperability are driving the evolution of cost prediction models by enabling real-time data analysis and dynamic project adjustments. The adoption of cloud-based platforms facilitates seamless collaboration among stakeholders, reducing manual errors and accelerating decision-making processes in construction budgeting.

Related Important Terms

Digital Quantity Surveying (DQS)

Digital Quantity Surveying (DQS) enhances construction cost management by integrating automated takeoff technologies, enabling precise material quantification and real-time data analysis. This fusion reduces estimation errors, accelerates project timelines, and improves budget accuracy compared to traditional quantity surveying methods.

Parametric Takeoff

Parametric takeoff in quantity surveying utilizes advanced software to generate precise material quantities by analyzing digital blueprints with customizable parameters, significantly reducing manual errors and project delays. This automated approach enhances accuracy and efficiency compared to traditional quantity surveying methods, enabling faster cost estimation and resource allocation in construction projects.

5D BIM Estimation

Quantity surveying integrates detailed cost analysis and risk management in construction projects, while automated takeoff enhances accuracy and speed by extracting precise measurements directly from 3D models. 5D BIM estimation combines these approaches, linking quantities with time and cost dimensions for comprehensive project forecasting and real-time budget control.

Data-Driven Cost Modeling

Quantity surveying leverages expert analysis and historical data to create accurate, detailed cost estimates, while automated takeoff utilizes digital tools and BIM technology to rapidly extract quantities from project plans. Combining these methods enhances data-driven cost modeling by integrating precise measurements with comprehensive market insights, improving budget accuracy and project financial management.

AI-powered Measurement

AI-powered measurement in construction significantly enhances quantity surveying by automating the takeoff process with precision, reducing manual errors and accelerating project timelines. Integrating advanced AI algorithms allows for real-time data extraction from digital plans, improving cost estimation accuracy and resource allocation.

Automated Bill of Quantities (ABQ)

Automated Bill of Quantities (ABQ) streamlines quantity surveying by leveraging advanced software to generate precise material and cost estimates directly from digital project plans, reducing human error and accelerating project timelines. This automation enhances accuracy in budgeting and resource allocation, providing real-time updates that improve decision-making compared to traditional manual takeoff methods.

Cloud-based Takeoff Solutions

Cloud-based takeoff solutions streamline quantity surveying by enabling real-time access to project data, enhancing collaboration and accuracy through automated measurements and centralized documentation. These platforms reduce manual errors and improve cost estimation efficiency compared to traditional quantity surveying methods.

Machine Learning Estimation

Machine learning estimation enhances quantity surveying by automating takeoff processes with higher accuracy and speed, reducing human error and improving cost prediction reliability. Integrating AI-driven algorithms into construction project management enables real-time data analysis and dynamic resource allocation, optimizing overall project efficiency.

Real-Time Cost Tracking

Quantity surveying offers detailed cost analysis based on project specifications, whereas automated takeoff integrates quickly with digital plans to provide real-time cost tracking and immediate budget adjustments. Real-time data from automated takeoff software enhances accuracy in material estimates and labor costs, enabling faster decision-making and minimizing financial risks on construction projects.

Rule-Based Quantity Extraction

Rule-based quantity extraction in quantity surveying leverages predefined algorithms to identify and quantify construction materials from digital plans with high accuracy, reducing human error. Automated takeoff systems enhance this process by integrating advanced rule-based models that streamline measurements, improve cost estimation efficiency, and support precise project budgeting.

Quantity Surveying vs Automated Takeoff Infographic

industrydif.com

industrydif.com