Mechanical fasteners provide reliable strength and easy disassembly in construction applications, making them ideal for temporary or adjustable joints. Structural adhesives offer uniform stress distribution and improved aesthetics by eliminating the need for holes or protrusions, enhancing durability and resistance to environmental factors. Selecting between these options depends on load requirements, material compatibility, and long-term performance expectations in the construction project.

Table of Comparison

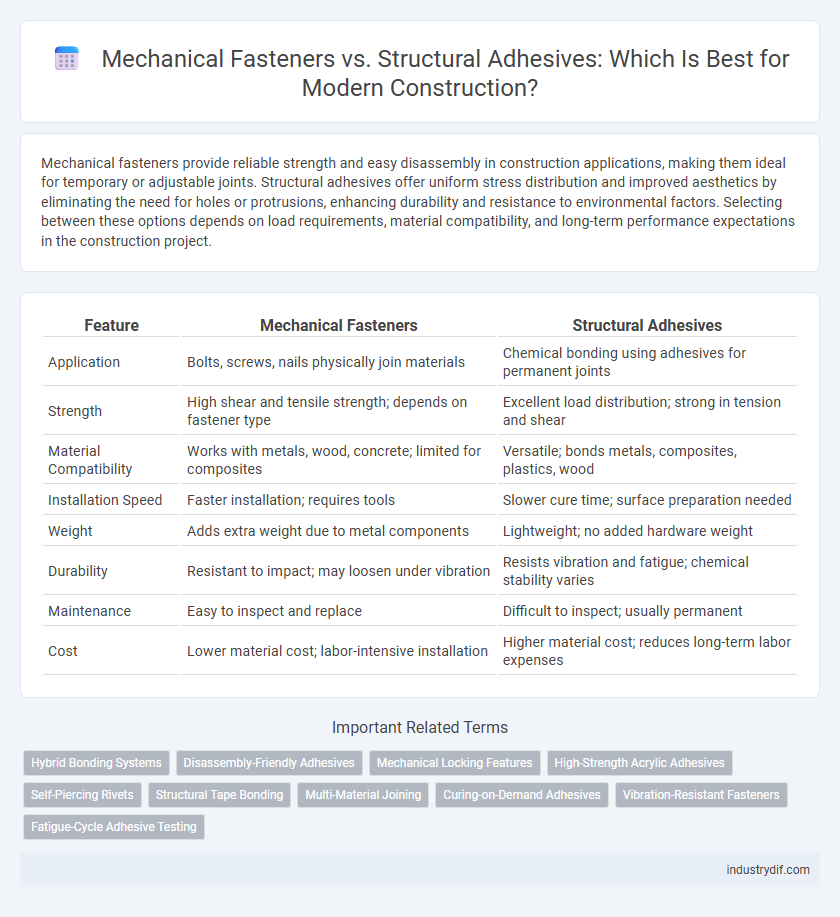

| Feature | Mechanical Fasteners | Structural Adhesives |

|---|---|---|

| Application | Bolts, screws, nails physically join materials | Chemical bonding using adhesives for permanent joints |

| Strength | High shear and tensile strength; depends on fastener type | Excellent load distribution; strong in tension and shear |

| Material Compatibility | Works with metals, wood, concrete; limited for composites | Versatile; bonds metals, composites, plastics, wood |

| Installation Speed | Faster installation; requires tools | Slower cure time; surface preparation needed |

| Weight | Adds extra weight due to metal components | Lightweight; no added hardware weight |

| Durability | Resistant to impact; may loosen under vibration | Resists vibration and fatigue; chemical stability varies |

| Maintenance | Easy to inspect and replace | Difficult to inspect; usually permanent |

| Cost | Lower material cost; labor-intensive installation | Higher material cost; reduces long-term labor expenses |

Introduction to Mechanical Fasteners and Structural Adhesives

Mechanical fasteners such as bolts, screws, and rivets are traditional joining methods that provide immediate and strong mechanical bonds by clamping components together. Structural adhesives offer a chemical bonding solution that distributes stress evenly across joints and enhances design flexibility by filling gaps and reducing weight. Both methods play critical roles in construction depending on factors like load requirements, environmental conditions, and material compatibility.

Definition and Types of Mechanical Fasteners

Mechanical fasteners are hardware devices used to join two or more components by interlocking, often removable without altering the joined parts. Common types include bolts, screws, nuts, rivets, and washers, each designed for specific load-bearing and assembly conditions in construction. These fasteners provide strong, reliable connections ideal for applications requiring disassembly or repositioning.

Overview of Structural Adhesives in Construction

Structural adhesives in construction offer high-strength bonding for diverse materials including metals, composites, and concrete, enabling load distribution across bonded surfaces. These adhesives provide superior resistance to vibration, fatigue, and environmental factors compared to mechanical fasteners, reducing the need for drilling or welding. Advances in epoxy, polyurethane, and acrylic formulations have expanded their application in structural panels, curtain walls, and prefabricated components, enhancing overall building integrity and aesthetic appeal.

Strength and Load-Bearing Capabilities Comparison

Mechanical fasteners such as bolts, screws, and rivets offer high shear and tensile strength, making them suitable for applications requiring reliable load-bearing connections in heavy construction. Structural adhesives provide uniform stress distribution and resistance to fatigue, enhancing joint durability in materials susceptible to cracking or deformation. While mechanical fasteners excel in immediate load support, structural adhesives contribute to improved long-term structural integrity under dynamic loads.

Durability and Environmental Resistance

Mechanical fasteners such as bolts and screws offer high durability through physical interlocking but can be prone to corrosion and loosening under environmental stress. Structural adhesives provide excellent environmental resistance, creating a protective bond that resists moisture, chemicals, and temperature fluctuations better than many fasteners. Choosing between these depends on specific project requirements for long-term performance and exposure conditions.

Installation Methods and Application Processes

Mechanical fasteners require drilling, aligning, and securing components with screws, bolts, or nails, demanding precise hole placement and torque control during installation. Structural adhesives involve surface preparation such as cleaning and priming, followed by applying adhesive and curing under specific temperature and pressure conditions to ensure bonding strength. Installation time for adhesives can be longer due to curing, while mechanical fasteners offer immediate load-bearing capacity and easier disassembly.

Cost Efficiency and Material Savings

Mechanical fasteners often incur higher labor and material costs due to drilling, insertion, and potential rework, while structural adhesives provide cost efficiency by reducing assembly time and minimizing the need for additional components. Structural adhesives enable significant material savings by allowing for thinner, lighter substrates without compromising joint strength, unlike mechanical fasteners which require overlap areas and fastener holes that weaken the material. Embracing adhesives can lead to lower total installation costs and optimized material usage in construction projects.

Design Flexibility and Versatility

Mechanical fasteners provide robust joint integrity with easy disassembly, suitable for applications requiring frequent maintenance or adjustments. Structural adhesives offer superior design flexibility by bonding dissimilar materials and distributing stress evenly across surfaces, enhancing durability and aesthetic appeal. Combining both methods allows engineers to optimize structural performance and adapt to complex design requirements in modern construction projects.

Common Industry Use Cases and Examples

Mechanical fasteners such as bolts, screws, and rivets are widely used in construction for joining steel beams, fastening drywall, and securing framing components due to their high load-bearing capacity and ease of inspection. Structural adhesives find common application in bonding composite panels, laminating wood elements, and sealing curtain wall systems, offering enhanced durability and uniform load distribution without penetrating the materials. Both methods are often specified based on structural requirements, material compatibility, and environmental exposure to optimize building performance and longevity.

Selection Criteria and Decision-Making Factors

Selecting between mechanical fasteners and structural adhesives depends on factors like load type, material compatibility, and environmental conditions. Mechanical fasteners offer high strength and ease of inspection but may induce stress concentrations, while structural adhesives provide uniform stress distribution and improved aesthetics yet require surface preparation and curing time. Decision-making hinges on balancing strength requirements, durability, joint design, and installation constraints to optimize structural performance.

Related Important Terms

Hybrid Bonding Systems

Hybrid bonding systems combine mechanical fasteners and structural adhesives to enhance load distribution and improve joint durability in construction applications. This approach optimizes stress resistance, reduces vibration, and provides superior corrosion protection compared to using mechanical fasteners or adhesives alone.

Disassembly-Friendly Adhesives

Disassembly-friendly adhesives in construction offer a sustainable alternative to mechanical fasteners by enabling easy separation of bonded components without damage, facilitating repair, recycling, and reuse. These adhesives improve maintenance efficiency and reduce waste by maintaining strong bonds during use while allowing controlled debonding through stimuli like heat or chemicals.

Mechanical Locking Features

Mechanical fasteners provide superior mechanical locking features through threads, ribs, or interlocking components, ensuring immediate and reliable joint strength in construction applications. Structural adhesives rely on chemical bonds, which offer uniform stress distribution but lack the instant mechanical interlock that fasteners deliver for dynamic load resistance.

High-Strength Acrylic Adhesives

High-strength acrylic adhesives provide superior bonding in construction applications by delivering enhanced shear and peel strength compared to traditional mechanical fasteners. These adhesives offer improved load distribution and resistance to environmental factors, ensuring durable and reliable structural joints without the need for drilling or welding.

Self-Piercing Rivets

Self-piercing rivets provide durable mechanical fastening by penetrating materials without pre-drilled holes, ensuring strong joints in automotive and aerospace construction. Compared to structural adhesives, they offer immediate load-bearing capacity and facilitate disassembly, enhancing maintenance efficiency in metal and composite assemblies.

Structural Tape Bonding

Structural tape bonding offers enhanced load distribution and vibration resistance compared to traditional mechanical fasteners, reducing stress concentrations and material fatigue in construction applications. Its ability to create continuous bonds on diverse substrates improves joint durability and accelerates assembly processes, making it an efficient alternative for modern structural connections.

Multi-Material Joining

Mechanical fasteners such as bolts and screws provide reliable, removable connections ideal for multi-material joining in construction, especially when accommodating thermal expansion and differing material properties. Structural adhesives offer uniform stress distribution and enhanced corrosion resistance, making them suitable for bonding dissimilar materials like metals, composites, and plastics in complex assemblies.

Curing-on-Demand Adhesives

Curing-on-demand adhesives offer precise control over bonding times in construction, improving efficiency compared to traditional mechanical fasteners that require pre-drilled holes and torque application. These adhesives enhance structural integrity by providing uniform load distribution and eliminating stress concentrations commonly associated with bolts and rivets.

Vibration-Resistant Fasteners

Vibration-resistant fasteners, such as locknuts and spring washers, provide superior mechanical stability in construction by preventing loosening under dynamic loads, outperforming many structural adhesives in high-vibration environments. These fasteners maintain joint integrity and ease of maintenance, making them essential for applications involving heavy machinery and seismic activity.

Fatigue-Cycle Adhesive Testing

Fatigue-cycle adhesive testing evaluates the durability of structural adhesives under repetitive loading conditions, highlighting their superior fatigue resistance compared to mechanical fasteners such as bolts and rivets. This testing ensures adhesives maintain bond integrity and prevent joint failure in dynamic construction applications where cyclic stress is prevalent.

Mechanical Fasteners vs Structural Adhesives Infographic

industrydif.com

industrydif.com