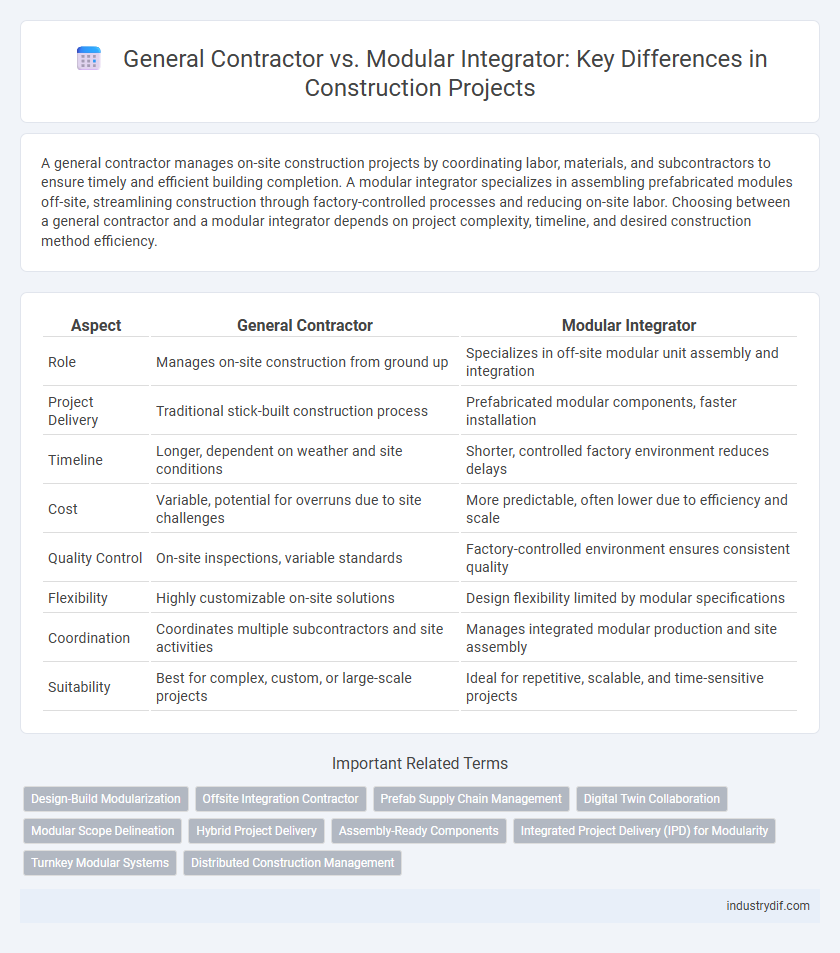

A general contractor manages on-site construction projects by coordinating labor, materials, and subcontractors to ensure timely and efficient building completion. A modular integrator specializes in assembling prefabricated modules off-site, streamlining construction through factory-controlled processes and reducing on-site labor. Choosing between a general contractor and a modular integrator depends on project complexity, timeline, and desired construction method efficiency.

Table of Comparison

| Aspect | General Contractor | Modular Integrator |

|---|---|---|

| Role | Manages on-site construction from ground up | Specializes in off-site modular unit assembly and integration |

| Project Delivery | Traditional stick-built construction process | Prefabricated modular components, faster installation |

| Timeline | Longer, dependent on weather and site conditions | Shorter, controlled factory environment reduces delays |

| Cost | Variable, potential for overruns due to site challenges | More predictable, often lower due to efficiency and scale |

| Quality Control | On-site inspections, variable standards | Factory-controlled environment ensures consistent quality |

| Flexibility | Highly customizable on-site solutions | Design flexibility limited by modular specifications |

| Coordination | Coordinates multiple subcontractors and site activities | Manages integrated modular production and site assembly |

| Suitability | Best for complex, custom, or large-scale projects | Ideal for repetitive, scalable, and time-sensitive projects |

Defining General Contractors in Construction

General contractors in construction manage all aspects of a building project, coordinating subcontractors, materials, and schedules to ensure timely completion. They hold primary contracts with clients and oversee on-site operations, quality control, and regulatory compliance. Their expertise spans traditional construction methods, contrasting with modular integrators who focus on prefabricated components assembly.

What is a Modular Integrator?

A modular integrator coordinates the design, fabrication, transportation, and installation of prefabricated building modules to streamline construction schedules and improve project efficiency. Unlike a general contractor who manages overall site construction, the modular integrator specializes in assembling pre-built components in a controlled factory environment. This approach reduces on-site labor, minimizes delays, and enhances quality control through precision manufacturing processes.

Key Responsibilities: General Contractor vs Modular Integrator

General contractors oversee entire construction projects, managing on-site labor, scheduling, subcontractors, and compliance with building codes to ensure timely and budget-compliant delivery. Modular integrators specialize in coordinating prefabricated module production, transportation, and assembly, ensuring seamless integration with site infrastructure and overall design specifications. Both roles require rigorous project management but differ in scope, with general contractors handling broader construction phases and modular integrators focusing on off-site fabrication and on-site installation efficiency.

Project Delivery Methods Compared

General Contractors typically oversee traditional project delivery methods such as Design-Bid-Build, managing on-site construction from ground-up with subcontractors coordinating trades and schedules. Modular Integrators specialize in Modular Construction delivery, fabricating standardized building components off-site in controlled environments to accelerate timelines and enhance quality control. Compared to General Contractors, Modular Integrators reduce on-site labor demands, minimize weather delays, and enable parallel site prep and module fabrication, streamlining the overall project delivery process.

Cost Considerations: Traditional vs Modular Construction

General contractors manage traditional construction projects with on-site labor and materials, often resulting in higher labor costs and longer timelines due to weather delays and scheduling conflicts. Modular integrators streamline costs by fabricating building components off-site in controlled environments, reducing labor expenses, minimizing material waste, and accelerating project completion. Comparative studies indicate modular construction can lower overall project costs by 10-20%, primarily through faster delivery, reduced site disruptions, and standardized factory processes.

Timeline and Efficiency Differences

General contractors typically manage traditional construction projects on-site, often resulting in longer timelines due to sequential scheduling and weather dependencies. Modular integrators streamline the process by fabricating components off-site in controlled environments, significantly reducing construction time and minimizing delays. This efficiency translates to faster project completion and potential cost savings by overlapping fabrication and site preparation phases.

Quality Control: Conventional vs Modular Approaches

Quality control in conventional construction relies heavily on on-site inspections and manual oversight, which can lead to variability due to environmental factors and human error. In contrast, modular integrators employ factory-controlled settings with standardized processes, resulting in consistent quality and reduced defects. This controlled environment minimizes rework and enhances precision, ultimately improving project timelines and reliability.

Collaboration and Team Structure

General contractors oversee traditional construction projects by managing subcontractors and coordinating on-site activities, while modular integrators specialize in off-site prefabrication and assembly of building modules. Effective collaboration between general contractors and modular integrators requires integrated project management systems and clear communication channels to align schedules, quality standards, and logistics. A hybrid team structure combining on-site supervision from general contractors and off-site expertise from modular integrators enhances efficiency and reduces construction timelines.

Regulatory Compliance and Permitting

General contractors manage regulatory compliance by coordinating onsite inspections and ensuring all construction phases meet local building codes and permit requirements. Modular integrators focus on factory-produced components, requiring specialized compliance with manufacturing standards and coordination with local authorities for installation permits. Both roles demand thorough documentation and adherence to safety regulations, but modular integration often streamlines permitting through controlled factory environments.

Choosing the Right Partner for Your Construction Project

Selecting the right partner for your construction project hinges on understanding the distinct roles of a general contractor and a modular integrator. General contractors oversee on-site construction, coordinating trades and managing schedules, while modular integrators specialize in off-site prefab manufacturing processes to deliver building components efficiently. Evaluating project complexity, timeline constraints, and integration expertise ensures the choice aligns with budget goals and quality standards.

Related Important Terms

Design-Build Modularization

General Contractors oversee traditional construction projects by coordinating on-site labor, materials, and scheduling, while Modular Integrators specialize in design-build modularization, streamlining the process by combining architectural design, factory fabrication, and on-site assembly to reduce construction time and improve quality control. Design-build modularization leverages off-site prefabrication to enhance project efficiency, cost predictability, and sustainability, making Modular Integrators critical for complex, fast-tracked construction projects.

Offsite Integration Contractor

Offsite Integration Contractors specialize in assembling pre-fabricated modular components at a controlled facility, ensuring higher precision and reduced onsite construction time compared to traditional General Contractors who manage all phases of conventional onsite building. This approach streamlines project delivery, enhances quality control, and minimizes weather-related delays by integrating design, fabrication, and installation processes offsite.

Prefab Supply Chain Management

General contractors oversee traditional on-site construction processes, coordinating subcontractors and managing project timelines, while modular integrators specialize in prefabricated components, optimizing supply chain management through controlled factory environments and just-in-time delivery. Efficient prefab supply chain management by modular integrators reduces material waste, shortens construction schedules, and enhances quality control compared to conventional general contracting methods.

Digital Twin Collaboration

General contractors manage on-site construction activities, ensuring physical project execution aligns with schedules and budgets, while modular integrators specialize in off-site manufacturing of prefabricated modules, leveraging digital twin collaboration to enhance precision and streamline integration. Digital twin technology enables real-time data synchronization between both parties, improving coordination, reducing errors, and accelerating project delivery in complex construction workflows.

Modular Scope Delineation

Modular integrators specialize in off-site construction, managing the complete modular scope including design coordination, fabrication, and transportation of preassembled units to ensure seamless on-site installation. This delineation contrasts with general contractors who primarily oversee traditional on-site construction activities, subcontractor management, and overall project execution.

Hybrid Project Delivery

Hybrid project delivery combines the strengths of general contractors and modular integrators, optimizing construction timelines and cost efficiency by blending traditional onsite methods with prefabricated modular components. This approach enhances project flexibility, reduces risks, and ensures seamless coordination between design, fabrication, and assembly phases.

Assembly-Ready Components

General contractors oversee traditional on-site construction processes involving raw materials and sequential task coordination, while modular integrators specialize in assembling pre-fabricated, assembly-ready components in controlled factory settings to enhance quality and reduce construction timelines. Utilizing assembly-ready components allows modular integrators to minimize on-site labor, improve precision, and accelerate project delivery compared to conventional general contracting methods.

Integrated Project Delivery (IPD) for Modularity

General contractors traditionally oversee all aspects of construction projects, coordinating labor, materials, and schedules, while modular integrators specialize in assembling prefabricated components to streamline building processes. Integrated Project Delivery (IPD) enhances modularity by fostering real-time collaboration among owners, architects, general contractors, and modular integrators, reducing waste, accelerating timelines, and improving overall project efficiency.

Turnkey Modular Systems

Turnkey modular systems streamline construction by allowing general contractors to oversee traditional site-built projects, while modular integrators specialize in prefabricated modules assembled off-site for faster completion and reduced on-site labor. Integrators coordinate design, manufacturing, and installation processes to deliver fully-finished modules, offering efficiency and quality control that complements general contractors' project management expertise.

Distributed Construction Management

General contractors oversee traditional on-site construction processes, coordinating subcontractors, materials, and schedules to ensure project completion. Modular integrators specialize in distributed construction management by assembling prefabricated modules in controlled factory environments, reducing site disruption and accelerating project timelines.

General Contractor vs Modular Integrator Infographic

industrydif.com

industrydif.com