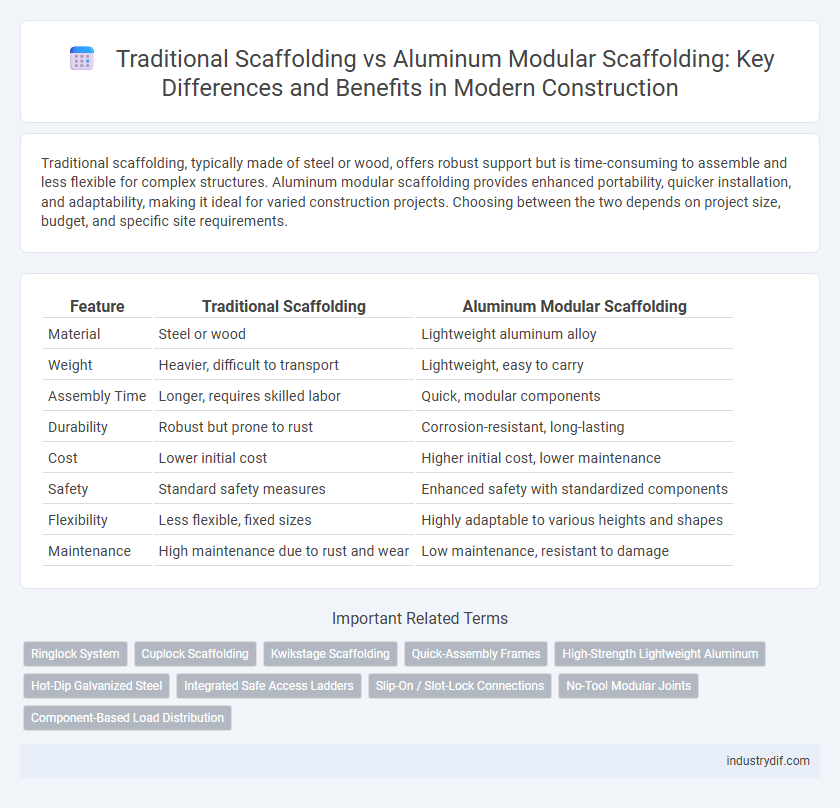

Traditional scaffolding, typically made of steel or wood, offers robust support but is time-consuming to assemble and less flexible for complex structures. Aluminum modular scaffolding provides enhanced portability, quicker installation, and adaptability, making it ideal for varied construction projects. Choosing between the two depends on project size, budget, and specific site requirements.

Table of Comparison

| Feature | Traditional Scaffolding | Aluminum Modular Scaffolding |

|---|---|---|

| Material | Steel or wood | Lightweight aluminum alloy |

| Weight | Heavier, difficult to transport | Lightweight, easy to carry |

| Assembly Time | Longer, requires skilled labor | Quick, modular components |

| Durability | Robust but prone to rust | Corrosion-resistant, long-lasting |

| Cost | Lower initial cost | Higher initial cost, lower maintenance |

| Safety | Standard safety measures | Enhanced safety with standardized components |

| Flexibility | Less flexible, fixed sizes | Highly adaptable to various heights and shapes |

| Maintenance | High maintenance due to rust and wear | Low maintenance, resistant to damage |

Introduction to Scaffolding Systems in Construction

Traditional scaffolding in construction typically utilizes steel or timber components, offering high load capacity but involves longer assembly times and heavier weight, impacting project efficiency. Aluminum modular scaffolding provides lightweight, corrosion-resistant structures with quick assembly and adjustable configurations, enhancing worker safety and reducing labor costs. Selecting the appropriate scaffolding system depends on factors such as project scale, site accessibility, and budget constraints.

Overview of Traditional Scaffolding

Traditional scaffolding, typically made from steel and wood, remains widely used in construction due to its robust strength and cost-effectiveness for large-scale projects. It requires extensive assembly and disassembly time, often demanding skilled labor and additional safety measures. Despite being heavier and less flexible than aluminum modular scaffolding, traditional scaffolding offers high load-bearing capacity suitable for heavy-duty construction tasks.

Key Features of Aluminum Modular Scaffolding

Aluminum modular scaffolding offers lightweight construction and easy assembly, enhancing worker productivity and site safety compared to traditional scaffolding. Its corrosion-resistant properties and adaptable design support diverse project requirements, reducing maintenance costs and downtime. The modular system allows for efficient height and length adjustments, promoting flexibility in complex construction environments.

Material Composition and Durability

Traditional scaffolding is typically made from steel or timber, offering robust strength but often being heavier and prone to corrosion or rot over time, which affects long-term durability. Aluminum modular scaffolding utilizes lightweight aluminum alloys that resist rust and corrosion, enhancing portability and longevity in various weather conditions. The choice between steel or timber and aluminum materials significantly impacts maintenance costs, load-bearing capacity, and lifespan of the scaffolding system on construction sites.

Load Capacity and Structural Strength

Traditional scaffolding, typically made from steel or timber, offers high load capacity and robust structural strength suitable for heavy-duty construction tasks. Aluminum modular scaffolding provides a lightweight alternative with excellent corrosion resistance while maintaining substantial load-bearing capabilities, ideal for quicker assembly and flexible use. Choosing between them depends on project requirements, balancing the need for maximum load capacity and ease of handling.

Flexibility and Adaptability on Site

Traditional scaffolding offers solid structural support but lacks the flexibility required for complex or frequently changing site layouts, often resulting in longer assembly times. Aluminum modular scaffolding provides superior adaptability with lightweight, interchangeable components that can be quickly configured to accommodate diverse building shapes and heights. This modular system enhances on-site efficiency by allowing rapid adjustments and reconfigurations, reducing labor costs and project delays.

Installation and Dismantling Efficiency

Traditional scaffolding requires extensive manual labor and time for installation and dismantling, often involving multiple workers and specialized skills. Aluminum modular scaffolding features lightweight components and quick-connect mechanisms, significantly reducing setup and teardown time while enhancing worker safety. This efficiency translates to lower labor costs and faster project timelines in construction settings.

Safety Standards and Compliance

Traditional scaffolding and aluminum modular scaffolding both meet strict safety standards outlined by OSHA and ANSI, but aluminum modular systems offer enhanced compliance through standardized components that reduce assembly errors. The lightweight nature of aluminum scaffolding improves worker stability and minimizes fatigue, contributing to safer work conditions on construction sites. Regular inspections and adherence to manufacturer guidelines ensure both scaffolding types maintain compliance with load-bearing requirements and fall protection regulations.

Cost Implications and Budget Considerations

Traditional scaffolding involves higher labor costs and longer installation times due to its heavy components and manual assembly process, impacting overall project budgets significantly. Aluminum modular scaffolding offers cost savings through faster setup, reduced labor expenses, and lower transportation costs owing to its lightweight and modular nature. Budget considerations should weigh upfront material expenses against long-term efficiency and reuse potential, where aluminum systems often provide better value on large-scale or repeated projects.

Choosing the Right Scaffolding for Your Project

Traditional scaffolding offers robust support and cost-effectiveness for long-term, heavy-duty construction projects, while aluminum modular scaffolding provides lightweight, flexible configurations ideal for complex structures and rapid assembly. Assess project scale, duration, load requirements, and site accessibility to determine the most efficient scaffolding system. Prioritizing safety standards and ease of customization ensures optimal performance and worker protection.

Related Important Terms

Ringlock System

Traditional scaffolding, typically made from steel tubes and couplers, offers robust strength but lacks the quick assembly and flexibility of aluminum modular scaffolding systems like the Ringlock system. The Ringlock system features pre-engineered rosettes and lightweight aluminum components, enabling faster construction, enhanced safety, and greater adaptability on complex building sites.

Cuplock Scaffolding

Cuplock scaffolding, a type of traditional scaffolding, offers robust load-bearing capacity and straightforward installation through its unique locking cup system, making it suitable for heavy-duty construction tasks. Aluminum modular scaffolding provides increased flexibility and lighter weight, enhancing worker efficiency and reducing setup time, while maintaining compatibility with Cuplock components for versatile project applications.

Kwikstage Scaffolding

Kwikstage scaffolding, a popular form of traditional scaffolding, offers robust steel components ideal for heavy-duty construction projects requiring strong load-bearing capacity and durability. In contrast, aluminum modular scaffolding provides lightweight, corrosion-resistant solutions with faster assembly times, enhancing efficiency on sites where portability and speed are critical.

Quick-Assembly Frames

Traditional scaffolding relies on labor-intensive assembly of individual components, resulting in longer setup times and increased labor costs, while aluminum modular scaffolding features quick-assembly frames designed for rapid installation and dismantling, significantly reducing project timelines. The lightweight aluminum frames enhance worker mobility and safety, offering a durable yet flexible solution that adapts efficiently to complex construction site demands.

High-Strength Lightweight Aluminum

High-strength lightweight aluminum in modular scaffolding significantly enhances construction efficiency by providing superior load-bearing capacity while reducing overall structure weight compared to traditional steel scaffolding. This advantage allows for faster assembly, increased safety, and improved worker mobility on job sites.

Hot-Dip Galvanized Steel

Hot-dip galvanized steel used in traditional scaffolding provides superior corrosion resistance and durability, making it ideal for long-term construction projects exposed to harsh weather conditions. In contrast, aluminum modular scaffolding often sacrifices some strength for lightweight benefits but lacks the enhanced rust protection offered by the galvanized steel coating.

Integrated Safe Access Ladders

Traditional scaffolding relies on separate, often cumbersome safe access ladders that can slow down assembly and pose safety risks, whereas aluminum modular scaffolding features integrated safe access ladders designed for quick installation and enhanced worker safety. The modular design improves site efficiency by providing stable, built-in ladders that reduce the likelihood of falls and streamline access across multiple levels.

Slip-On / Slot-Lock Connections

Slip-on and slot-lock connections in traditional scaffolding provide secure, straightforward assembly but often require more manual labor and time compared to aluminum modular scaffolding. Aluminum modular systems utilize advanced slip-on and slot-lock mechanisms that enhance safety, reduce installation time by up to 40%, and improve adaptability on complex construction sites.

No-Tool Modular Joints

Traditional scaffolding typically relies on fixed, tool-intensive connections that prolong assembly time and limit flexibility, whereas aluminum modular scaffolding utilizes no-tool modular joints that enable rapid, tool-free assembly with enhanced adaptability and reduced labor costs. These no-tool joints improve on-site safety and efficiency by allowing quick adjustments and secure connections without specialized equipment, making aluminum modular scaffolding ideal for dynamic construction environments.

Component-Based Load Distribution

Traditional scaffolding relies on fixed components that distribute loads unevenly, often leading to stress concentrations and potential structural weaknesses. Aluminum modular scaffolding employs interlocking components designed for balanced load distribution, enhancing stability and safety on construction sites.

Traditional Scaffolding vs Aluminum Modular Scaffolding Infographic

industrydif.com

industrydif.com