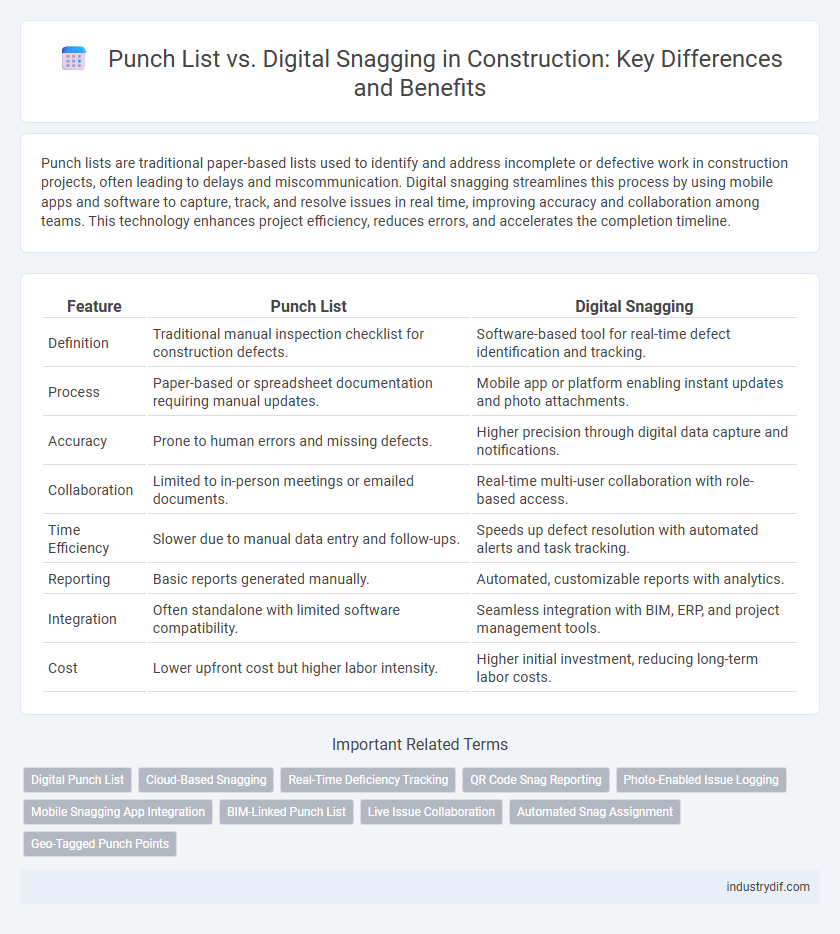

Punch lists are traditional paper-based lists used to identify and address incomplete or defective work in construction projects, often leading to delays and miscommunication. Digital snagging streamlines this process by using mobile apps and software to capture, track, and resolve issues in real time, improving accuracy and collaboration among teams. This technology enhances project efficiency, reduces errors, and accelerates the completion timeline.

Table of Comparison

| Feature | Punch List | Digital Snagging |

|---|---|---|

| Definition | Traditional manual inspection checklist for construction defects. | Software-based tool for real-time defect identification and tracking. |

| Process | Paper-based or spreadsheet documentation requiring manual updates. | Mobile app or platform enabling instant updates and photo attachments. |

| Accuracy | Prone to human errors and missing defects. | Higher precision through digital data capture and notifications. |

| Collaboration | Limited to in-person meetings or emailed documents. | Real-time multi-user collaboration with role-based access. |

| Time Efficiency | Slower due to manual data entry and follow-ups. | Speeds up defect resolution with automated alerts and task tracking. |

| Reporting | Basic reports generated manually. | Automated, customizable reports with analytics. |

| Integration | Often standalone with limited software compatibility. | Seamless integration with BIM, ERP, and project management tools. |

| Cost | Lower upfront cost but higher labor intensity. | Higher initial investment, reducing long-term labor costs. |

Introduction to Punch List and Digital Snagging

Punch List is a traditional construction process that involves manually documenting incomplete or defective work at the end of a project for correction before final handover. Digital Snagging leverages mobile and cloud-based technology to streamline this task, enabling real-time updates, photo documentation, and easier communication among project stakeholders. Implementing Digital Snagging improves accuracy, reduces turnaround times, and enhances project quality control compared to conventional punch list methods.

Defining Punch List in Construction

A punch list in construction is a detailed document identifying incomplete or faulty work that contractors must address before project completion. It serves as a critical quality control tool ensuring all contractual obligations and construction standards are met. Traditional punch lists are often paper-based, while digital snagging enhances accuracy and efficiency through mobile applications and real-time updates.

Understanding Digital Snagging Systems

Digital snagging systems streamline the punch list process by enabling real-time defect identification and tracking using mobile devices and cloud-based platforms, improving communication between site teams and project managers. These systems integrate photos, location data, and task assignments, boosting accuracy and reducing manual errors traditionally associated with paper-based punch lists. Embracing digital snagging enhances project transparency, accelerates issue resolution, and supports efficient construction project closeout.

Key Differences Between Punch List and Digital Snagging

Punch lists are traditional, paper-based reports used to identify and document construction defects at the end of a project, whereas digital snagging utilizes software platforms and mobile apps to capture, track, and manage issues in real-time. Digital snagging improves accuracy and communication by allowing instant photo uploads, GPS tagging, and automated status updates, significantly reducing human error and project delays. Key differences include the speed of issue resolution, ease of collaboration among contractors, and enhanced data analytics for quality control through digital snagging tools.

Advantages of Traditional Punch Lists

Traditional punch lists provide a tangible, hands-on approach that allows contractors and clients to physically verify construction defects before project closeout. Their simplicity requires no specialized technology or training, making them accessible on any job site regardless of digital infrastructure. This method also facilitates direct communication and immediate resolution between subcontractors and project managers, ensuring clarity in task identification and completion.

Benefits of Digital Snagging Solutions

Digital snagging solutions streamline the punch list process by enabling real-time defect tracking and instant communication between contractors and clients, reducing project delays and costly rework. These tools leverage mobile apps and cloud-based platforms to provide accurate, up-to-date documentation, improving accountability and transparency on construction sites. Enhanced data analytics from digital snagging also facilitate proactive quality control, accelerating project completion and boosting overall efficiency.

Impact on Project Timeline and Quality Control

Punch List processes often lead to delays in project timelines due to manual tracking and communication inefficiencies, increasing the risk of overlooked defects. Digital snagging enhances quality control by providing real-time issue reporting, automated tracking, and instant collaboration, significantly reducing rework time. Integrating digital tools streamlines completion verification, improves accountability, and accelerates project closeout with higher precision.

Common Challenges with Each Approach

Punch lists often suffer from manual errors, delayed updates, and difficulty tracking issues across multiple teams, causing project delays and miscommunication. Digital snagging addresses some challenges with real-time updates and centralized data but can face obstacles like software adoption resistance and integration issues with existing workflows. Both methods require effective communication and streamlined processes to minimize errors and ensure timely project completion.

Best Practices for Implementation

Implementing a digital snagging system streamlines the punch list process by enabling real-time issue tracking and resolution, improving communication among stakeholders. Best practices include integrating mobile applications for on-site data entry, maintaining a centralized database for transparent progress monitoring, and setting clear deadlines to ensure timely closure of defects. Leveraging automated notifications and analytics enhances accountability and helps prioritize critical tasks, driving efficient project completion.

Future Trends in Construction Quality Management

Digital snagging is revolutionizing construction quality management by enabling real-time issue identification through mobile apps and cloud-based platforms, vastly improving accuracy compared to traditional punch lists. Future trends emphasize integration with Building Information Modeling (BIM) and AI-driven analytics to predict and prevent defects before project completion. Enhanced collaboration between subcontractors and clients via digital snagging tools will streamline workflows, reduce rework costs, and accelerate project delivery timelines.

Related Important Terms

Digital Punch List

Digital Punch List streamlines construction project management by enabling real-time tracking, instant updates, and centralized documentation of defects and tasks. This technology enhances collaboration among contractors, architects, and clients, accelerating issue resolution and improving overall project efficiency.

Cloud-Based Snagging

Cloud-based snagging platforms streamline the punch list process by enabling real-time issue tracking, instant photo documentation, and seamless collaboration among project stakeholders, significantly reducing errors and delays. Leveraging cloud technology ensures that construction teams access up-to-date snag lists from any device, enhancing transparency and accelerating project closeout compared to traditional manual punch lists.

Real-Time Deficiency Tracking

Digital snagging offers real-time deficiency tracking through mobile applications and cloud-based platforms, streamlining the identification, assignment, and resolution of construction defects. Unlike traditional punch list methods relying on paper records and manual updates, digital snagging enhances accuracy, collaboration, and project efficiency by providing instant access to up-to-date information.

QR Code Snag Reporting

Punch list management traditionally involves manual documentation and tracking of construction defects, often leading to delays and errors. Digital snagging with QR code snag reporting streamlines the defect identification process by instantly linking issues to project data, enhancing accuracy and accelerating resolution times.

Photo-Enabled Issue Logging

Photo-enabled issue logging in digital snagging enhances accuracy by allowing real-time visual documentation of defects, ensuring clear communication and faster resolution compared to traditional paper-based punch lists. Integrating images directly into digital platforms reduces errors, streamlines collaboration, and improves accountability on construction sites.

Mobile Snagging App Integration

Punch lists traditionally rely on manual inspections and paper-based tracking, causing delays and errors, whereas digital snagging utilizes mobile snagging app integration to streamline defect identification and resolution in real-time. Mobile snagging apps enhance project efficiency by enabling instant photo capture, location tagging, and automated reporting, significantly reducing construction delays and improving communication among stakeholders.

BIM-Linked Punch List

BIM-linked punch lists enhance traditional punch list processes by integrating digital snagging directly into Building Information Modeling, enabling real-time issue tracking, precise location tagging, and collaborative resolution. This approach streamlines defect management, reduces on-site rework, and improves project delivery efficiency through automated updates and comprehensive data integration.

Live Issue Collaboration

Punch List processes often rely on manual documentation and delayed communication, leading to inefficiencies in resolving construction defects; Digital Snagging platforms enable real-time issue tracking and live collaboration among stakeholders, accelerating problem resolution and enhancing project transparency. Live issue collaboration through digital snagging tools integrates instant updates, photo evidence, and task assignment, streamlining the construction closeout phase and reducing rework costs.

Automated Snag Assignment

Automated snag assignment in digital snagging streamlines the punch list process by instantly categorizing and allocating tasks to relevant subcontractors based on predefined criteria, significantly reducing manual errors and project delays. This technology enhances accountability and real-time tracking, ensuring faster issue resolution compared to traditional punch list methods.

Geo-Tagged Punch Points

Geo-tagged punch points in digital snagging streamline construction quality control by precisely locating defects on-site through GPS coordinates, enhancing accuracy compared to traditional punch lists. This technology accelerates issue resolution and improves project documentation by integrating real-time spatial data with digital reporting platforms.

Punch List vs Digital Snagging Infographic

industrydif.com

industrydif.com