Thermal imaging detects heat anomalies in construction materials, enabling the identification of insulation failures and moisture intrusion quickly on-site. Digital twin analysis creates a comprehensive virtual model of a building, integrating real-time data and predicting structural performance over time. Combining thermal imaging with digital twin technology enhances accuracy in diagnosing issues and optimizing building efficiency throughout the construction lifecycle.

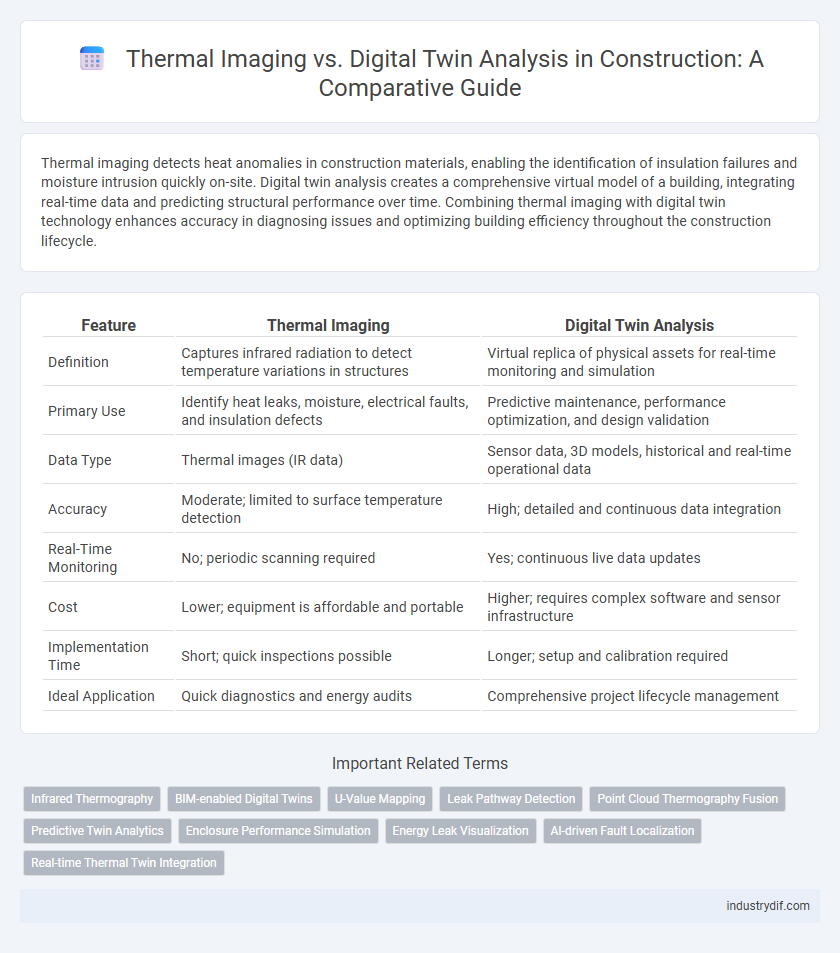

Table of Comparison

| Feature | Thermal Imaging | Digital Twin Analysis |

|---|---|---|

| Definition | Captures infrared radiation to detect temperature variations in structures | Virtual replica of physical assets for real-time monitoring and simulation |

| Primary Use | Identify heat leaks, moisture, electrical faults, and insulation defects | Predictive maintenance, performance optimization, and design validation |

| Data Type | Thermal images (IR data) | Sensor data, 3D models, historical and real-time operational data |

| Accuracy | Moderate; limited to surface temperature detection | High; detailed and continuous data integration |

| Real-Time Monitoring | No; periodic scanning required | Yes; continuous live data updates |

| Cost | Lower; equipment is affordable and portable | Higher; requires complex software and sensor infrastructure |

| Implementation Time | Short; quick inspections possible | Longer; setup and calibration required |

| Ideal Application | Quick diagnostics and energy audits | Comprehensive project lifecycle management |

Introduction to Thermal Imaging and Digital Twin Analysis in Construction

Thermal imaging in construction uses infrared technology to detect temperature variations, enabling early identification of insulation defects, moisture intrusion, and electrical issues within building structures. Digital twin analysis creates a dynamic, virtual replica of physical assets, allowing real-time monitoring, simulation, and optimization of construction processes and building performance. Combining these technologies enhances predictive maintenance and improves overall project efficiency by integrating thermal data into comprehensive digital models.

Key Principles of Thermal Imaging Technology

Thermal imaging technology in construction relies on detecting infrared radiation to visualize temperature variations across building surfaces, enabling the identification of heat leaks, moisture intrusion, and insulation defects. Its key principles include sensor sensitivity to infrared wavelengths, image resolution, and emissivity calibration, which ensure accurate thermal mapping of structures. This technology provides real-time, non-invasive diagnostics essential for energy efficiency assessments and preventive maintenance in building projects.

Fundamentals of Digital Twin Analysis

Digital Twin Analysis in construction involves creating a virtual replica of a physical building or infrastructure to monitor, simulate, and optimize performance in real time. Unlike Thermal Imaging, which captures surface temperature variations to detect issues like heat loss or moisture intrusion, Digital Twin Analysis integrates data from multiple sources, enabling comprehensive lifecycle management and predictive maintenance. This approach leverages IoT sensors, BIM models, and real-time analytics to enhance decision-making and improve project outcomes.

Comparative Accuracy in Defect Detection

Thermal imaging offers real-time visualization of temperature variations in building materials, providing accurate detection of insulation defects, moisture intrusion, and electrical hotspots. Digital twin analysis integrates sensor data into a dynamic 3D model, enabling precise tracking and prediction of structural anomalies over time with enhanced contextual insights. The comparative accuracy favors digital twins for comprehensive, longitudinal monitoring, while thermal imaging excels in immediate, localized defect identification.

Real-Time Monitoring Capabilities

Thermal imaging offers immediate detection of heat anomalies, enabling real-time identification of insulation failures, moisture intrusion, and electrical issues during construction. Digital twin analysis enhances real-time monitoring by integrating sensor data, providing a dynamic virtual model that predicts structural behavior and environmental changes as they occur. Combining thermal imaging with digital twin platforms maximizes real-time insight, improving decision-making accuracy and proactive issue resolution on construction sites.

Cost Implications and ROI Assessment

Thermal imaging technology in construction offers a cost-effective solution for real-time detection of heat loss, moisture intrusion, and electrical faults, reducing immediate maintenance expenses and improving energy efficiency. Digital twin analysis, although requiring higher initial investment for 3D modeling and sensor integration, provides comprehensive lifecycle insights that optimize asset management and prevent costly failures over time. Evaluating ROI, thermal imaging delivers quicker short-term savings, while digital twins yield substantial long-term value through predictive analytics and enhanced operational efficiency.

Data Integration and Visualization Differences

Thermal imaging captures real-time temperature variations on construction sites, providing immediate visual data for identifying insulation defects or moisture intrusion, whereas digital twin analysis integrates multi-source data to create comprehensive, interactive 3D models for ongoing structural monitoring and simulation. Thermal imaging data is primarily visual and limited to surface conditions, while digital twins combine thermal data with sensors, BIM models, and IoT inputs to deliver dynamic visualization and predictive analytics. The integration capability of digital twins enables enhanced decision-making through synchronized, multi-layered data, surpassing the isolated snapshot view thermal imaging offers.

Applications in Building Diagnostics

Thermal imaging identifies heat loss, moisture intrusion, and electrical faults by capturing infrared radiation, making it essential for real-time energy audits and maintenance in building diagnostics. Digital twin analysis creates a dynamic, virtual replica of a building's physical and operational characteristics to predict performance, optimize energy consumption, and simulate retrofit scenarios. Combining thermal imaging data with digital twins enhances predictive maintenance, improves fault detection accuracy, and supports sustainable building management strategies.

Scalability for Large Construction Projects

Thermal imaging provides real-time heat distribution data crucial for identifying insulation defects and energy losses in large construction projects, but its scalability is limited by on-site equipment and manual data collection constraints. Digital twin analysis offers a scalable solution by integrating sensor data, building information models (BIM), and real-time monitoring into a centralized virtual environment, enabling comprehensive project visualization and predictive maintenance across vast construction sites. Leveraging cloud computing and IoT connectivity, digital twins enhance decision-making efficiency and reduce downtime for complex, multi-phase developments.

Future Trends: Combining Thermal Imaging with Digital Twins

Integrating thermal imaging with digital twin analysis represents a transformative future trend in construction, enabling real-time monitoring of building performance and predictive maintenance through enhanced data visualization. This synergy allows for precise thermal anomaly detection within a digital replica, optimizing energy efficiency and reducing operational costs. Advanced AI algorithms further enhance this integration, facilitating dynamic simulations and proactive decision-making throughout the building lifecycle.

Related Important Terms

Infrared Thermography

Infrared thermography in construction offers precise detection of heat loss, moisture intrusion, and electrical faults by capturing thermal radiation, enabling effective building diagnostics and preventative maintenance. Digital twin analysis integrates these thermographic data into a dynamic virtual model, enhancing predictive analytics and real-time monitoring for optimized building performance.

BIM-enabled Digital Twins

BIM-enabled Digital Twins provide dynamic, real-time data integration and predictive analytics for construction project management, significantly enhancing decision-making accuracy compared to static thermal imaging, which primarily detects surface temperature variations and potential insulation defects. Leveraging BIM's 3D modeling capabilities, Digital Twins enable comprehensive performance monitoring and simulation throughout the building lifecycle, optimizing energy efficiency, structural integrity, and maintenance scheduling beyond what thermal imaging alone can achieve.

U-Value Mapping

Thermal imaging captures real-time surface temperature variations to identify insulation defects and heat loss, providing accurate U-value mapping across building envelopes. Digital twin analysis integrates BIM data and sensor inputs to simulate thermal performance, enabling dynamic U-value mapping for predictive energy efficiency assessments.

Leak Pathway Detection

Thermal imaging detects temperature variations on surfaces, identifying potential leak pathways by highlighting moist or cooler areas indicative of water intrusion. Digital twin analysis integrates sensor data and 3D modeling to simulate and predict leak progression, providing a dynamic and precise approach to leak pathway detection in construction projects.

Point Cloud Thermography Fusion

Point Cloud Thermography Fusion integrates thermal imaging data with 3D point clouds to enhance the accuracy of digital twin models in construction, enabling detailed thermal performance analysis of building envelopes. This fusion allows for precise detection of heat loss, moisture intrusion, and structural defects, improving energy efficiency assessments and preventative maintenance planning.

Predictive Twin Analytics

Predictive Twin Analytics leverages Digital Twin technology to simulate building performance, enabling proactive identification of thermal inefficiencies that traditional Thermal Imaging may miss. Integrating real-time sensor data with predictive models enhances construction outcomes by forecasting maintenance needs and optimizing energy consumption.

Enclosure Performance Simulation

Thermal imaging detects real-time heat loss and insulation defects in building enclosures, providing immediate visualization of thermal bridges and air leaks. Digital twin analysis simulates enclosure performance over time by integrating environmental data and material properties, enabling predictive insights into energy efficiency and durability.

Energy Leak Visualization

Thermal imaging detects energy leaks in buildings by capturing infrared radiation, providing real-time temperature variations on surfaces, while digital twin analysis integrates sensor data and 3D models to simulate and predict energy loss patterns throughout the entire structure. Combining thermal imaging with digital twin technology enhances accuracy in identifying insulation weaknesses and optimizes energy efficiency strategies in construction projects.

AI-driven Fault Localization

AI-driven fault localization enhances thermal imaging by rapidly detecting temperature anomalies in construction materials, enabling precise identification of insulation failures and moisture intrusion. Digital twin analysis complements this by simulating building behavior in real-time, using AI algorithms to predict fault propagation and optimize maintenance schedules.

Real-time Thermal Twin Integration

Real-time thermal twin integration combines thermal imaging data with digital twin technology to enable continuous monitoring of building performance, identifying heat loss, insulation defects, and moisture intrusion with high precision. This fusion enhances predictive maintenance, energy efficiency optimization, and improves construction quality assurance by providing dynamic, data-driven insights throughout the building lifecycle.

Thermal Imaging vs Digital Twin Analysis Infographic

industrydif.com

industrydif.com