Paper documentation in construction often leads to inefficiencies due to manual errors and difficulty in updating project changes in real time. Digital twins provide a dynamic, real-time virtual model of physical assets, allowing for enhanced visualization, simulation, and collaboration among stakeholders. This technology streamlines project management, reduces costs, and improves accuracy compared to traditional paper-based methods.

Table of Comparison

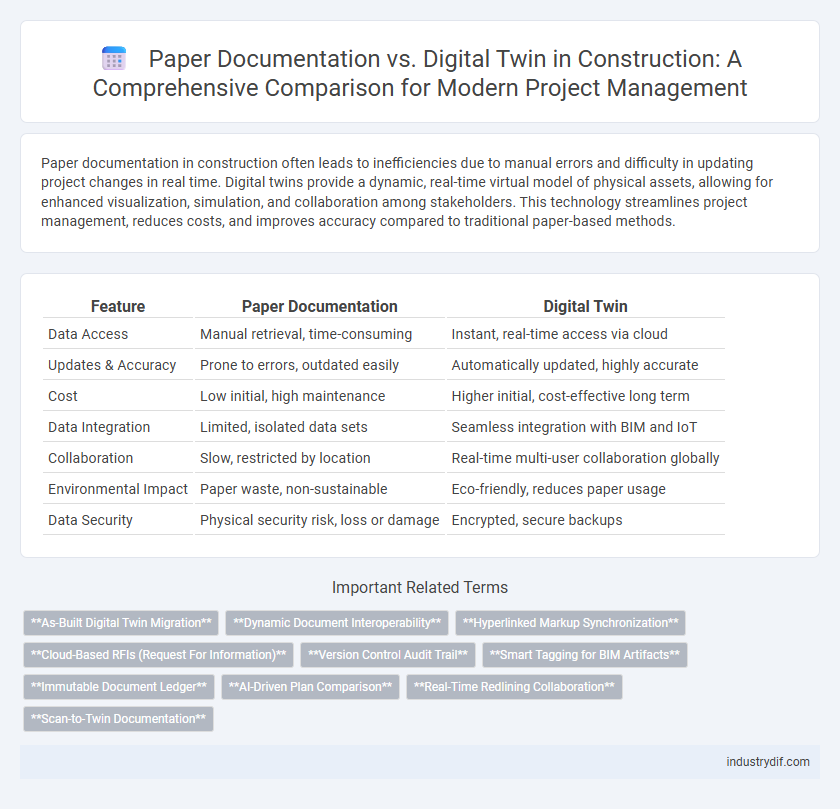

| Feature | Paper Documentation | Digital Twin |

|---|---|---|

| Data Access | Manual retrieval, time-consuming | Instant, real-time access via cloud |

| Updates & Accuracy | Prone to errors, outdated easily | Automatically updated, highly accurate |

| Cost | Low initial, high maintenance | Higher initial, cost-effective long term |

| Data Integration | Limited, isolated data sets | Seamless integration with BIM and IoT |

| Collaboration | Slow, restricted by location | Real-time multi-user collaboration globally |

| Environmental Impact | Paper waste, non-sustainable | Eco-friendly, reduces paper usage |

| Data Security | Physical security risk, loss or damage | Encrypted, secure backups |

Introduction to Paper Documentation and Digital Twin in Construction

Paper documentation in construction has traditionally involved physical blueprints, manuals, and project records essential for project planning, compliance, and progress tracking. Digital twin technology creates a dynamic, virtual replica of physical construction assets, enabling real-time monitoring, data integration, and predictive analytics throughout the project lifecycle. Transitioning from paper documentation to digital twins enhances accuracy, collaboration, and efficiency in construction management and execution.

Evolution of Documentation Methods in Construction

Construction documentation has evolved from traditional paper blueprints and manuals to advanced digital twin technologies, enabling real-time 3D modeling and data integration for enhanced project accuracy. Digital twins offer continuous updates, improved collaboration, and predictive analytics, reducing errors and rework compared to static paper records. This shift drives efficiency in project management, asset maintenance, and lifecycle analysis in the construction industry.

Defining Paper Documentation: Processes and Limitations

Paper documentation in construction involves the manual recording of project plans, permits, inspections, and change orders, often stored in physical folders or printed sheets. These processes are prone to errors, delays, and loss due to misplacement or damage, limiting real-time access and collaboration among stakeholders. The inability to update documents instantly hinders efficient project tracking, making paper workflows less adaptable compared to digital alternatives like Digital Twin technology.

Understanding Digital Twin Technology: Key Features and Functions

Digital Twin technology in construction creates a real-time virtual replica of physical assets, enabling detailed monitoring and simulation of building performance. Key features include integration with IoT sensors, data analytics, and predictive maintenance capabilities that improve project accuracy and reduce risks. Unlike traditional paper documentation, Digital Twins offer dynamic updates and interactive visualization, enhancing decision-making throughout the project lifecycle.

Comparative Efficiency: Paper vs. Digital Twin Workflows

Paper documentation in construction often leads to inefficiencies such as increased risk of errors, time-consuming manual updates, and difficulty in sharing real-time information across teams. Digital twin workflows enable seamless integration of data, real-time project monitoring, and enhanced collaboration, significantly reducing delays and miscommunication. Utilizing digital twins enhances accuracy and accelerates decision-making, leading to more efficient construction management compared to traditional paper-based methods.

Impact on Project Collaboration and Communication

Digital twin technology transforms construction project collaboration by enabling real-time data sharing and visualization, reducing miscommunication and delays compared to traditional paper documentation. Interactive 3D models and integrated sensor data enhance stakeholder engagement, allowing instant updates and more accurate decision-making. Paper documentation lacks dynamic updating and centralized access, often causing fragmented communication and slower response times in complex projects.

Data Accuracy and Information Accessibility

Paper documentation in construction often suffers from delays in updates and is prone to human error, limiting data accuracy and timely access. Digital twins provide real-time, precise representations of physical assets, ensuring accurate data integration and seamless information accessibility across all project stakeholders. Enhanced collaboration and immediate updates with digital twins significantly improve decision-making and reduce costly errors on construction sites.

Sustainability and Environmental Considerations

Digital twins significantly reduce the environmental impact of construction projects by minimizing the need for paper documentation, which often leads to excessive deforestation and waste. Utilizing real-time data and 3D modeling, digital twins optimize resource allocation, reduce material waste, and decrease carbon emissions associated with transportation and onsite errors. This sustainable approach enhances project efficiency while supporting green building certifications and long-term environmental stewardship.

Cost Implications: Short-Term and Long-Term Perspectives

Paper documentation in construction involves ongoing expenses such as printing, storage, and manual updates, leading to higher short-term costs and inefficiencies. Digital Twin technology requires significant initial investment in software, hardware, and training but reduces long-term costs by enabling real-time data access, streamlined project management, and predictive maintenance. Over time, the cost savings from improved accuracy and reduced rework make Digital Twins a more economically viable solution compared to traditional paper-based documentation.

Future Trends: Digital Twin Adoption in the Construction Industry

Digital twin technology is revolutionizing the construction industry by providing real-time, data-driven project simulations that enhance decision-making and reduce costly errors compared to traditional paper documentation. Future trends indicate widespread adoption of digital twins will improve collaboration, asset management, and predictive maintenance through integration with IoT sensors and AI analytics. Construction firms embracing digital twins can expect significant gains in efficiency, sustainability, and project lifecycle optimization.

Related Important Terms

As-Built Digital Twin Migration

Migrating paper documentation to an as-built digital twin enhances accuracy by enabling real-time updates and comprehensive 3D visualization, reducing errors inherent in manual record-keeping. This transition supports efficient project management, facilitates better facility maintenance, and improves lifecycle data accessibility across construction phases.

Dynamic Document Interoperability

Dynamic document interoperability in construction enhances project efficiency by enabling real-time synchronization between traditional paper documentation and digital twin models, allowing stakeholders to access up-to-date design changes and construction progress instantly. This integration reduces errors, accelerates decision-making, and ensures seamless collaboration across multidisciplinary teams through automated data exchanges and standardized information protocols.

Hyperlinked Markup Synchronization

Hyperlinked markup synchronization enables real-time updates and seamless access to interconnected project details within a digital twin, drastically reducing errors and miscommunication common in paper documentation. This integration enhances collaboration by allowing stakeholders to instantly navigate and verify changes across multiple digital documents and 3D models, streamlining construction workflows and improving project accuracy.

Cloud-Based RFIs (Request For Information)

Cloud-based RFIs streamline communication by enabling real-time access, collaboration, and updates across project teams, significantly reducing delays associated with traditional paper documentation. Digital twin integration enhances this process by providing a dynamic, 3D model reference that improves accuracy and traceability of information requests throughout construction phases.

Version Control Audit Trail

Digital twin technology offers a robust version control audit trail by continuously updating the 3D model with real-time data, ensuring precise tracking of design changes and construction phases. Paper documentation lacks this dynamic capability, often resulting in fragmented records and increased risk of errors during project audits and revisions.

Smart Tagging for BIM Artifacts

Smart tagging for BIM artifacts enhances accuracy in construction by embedding metadata directly into digital models, enabling seamless identification and retrieval compared to traditional paper documentation. This technology improves project coordination and reduces errors by providing real-time updates and comprehensive asset information within the digital twin environment.

Immutable Document Ledger

An immutable document ledger within digital twin technology offers secure, tamper-proof records of construction project documents, enhancing transparency and accountability compared to traditional paper documentation. This ledger ensures real-time updates and audit trails that eliminate risks of data loss or alteration, streamlining compliance and project management in the construction industry.

AI-Driven Plan Comparison

AI-driven plan comparison in construction leverages digital twin technology to enhance accuracy by automatically detecting discrepancies between original paper documentation and updated digital models. This approach reduces manual errors, accelerates project timelines, and ensures real-time synchronization of design changes for improved decision-making.

Real-Time Redlining Collaboration

Real-time redlining collaboration in construction drastically improves accuracy and efficiency by enabling team members to instantly annotate and update digital twin models, eliminating delays and errors common with paper documentation. This dynamic interaction fosters seamless communication, accelerates decision-making, and enhances project coordination across all stakeholders.

Scan-to-Twin Documentation

Scan-to-Twin documentation revolutionizes construction workflows by converting detailed 3D laser scans into precise digital twin models, enabling real-time project monitoring and enhanced asset management. This method outperforms traditional paper documentation by reducing errors, accelerating decision-making, and facilitating seamless integration with BIM and IoT systems.

Paper Documentation vs Digital Twin Infographic

industrydif.com

industrydif.com