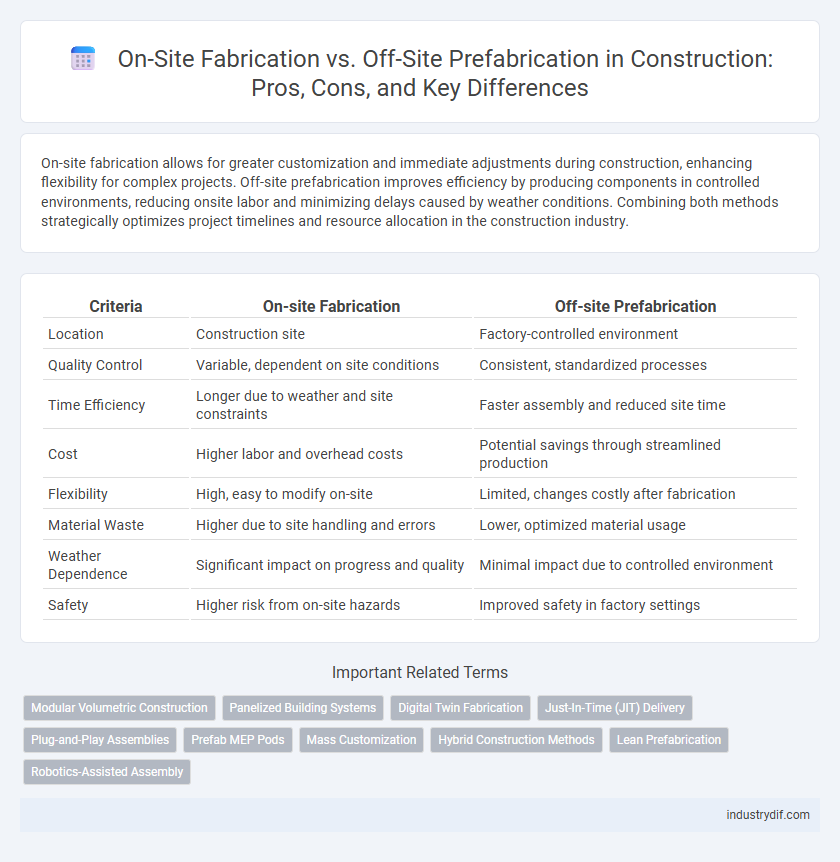

On-site fabrication allows for greater customization and immediate adjustments during construction, enhancing flexibility for complex projects. Off-site prefabrication improves efficiency by producing components in controlled environments, reducing onsite labor and minimizing delays caused by weather conditions. Combining both methods strategically optimizes project timelines and resource allocation in the construction industry.

Table of Comparison

| Criteria | On-site Fabrication | Off-site Prefabrication |

|---|---|---|

| Location | Construction site | Factory-controlled environment |

| Quality Control | Variable, dependent on site conditions | Consistent, standardized processes |

| Time Efficiency | Longer due to weather and site constraints | Faster assembly and reduced site time |

| Cost | Higher labor and overhead costs | Potential savings through streamlined production |

| Flexibility | High, easy to modify on-site | Limited, changes costly after fabrication |

| Material Waste | Higher due to site handling and errors | Lower, optimized material usage |

| Weather Dependence | Significant impact on progress and quality | Minimal impact due to controlled environment |

| Safety | Higher risk from on-site hazards | Improved safety in factory settings |

Introduction to On-site Fabrication and Off-site Prefabrication

On-site fabrication involves constructing building components directly at the construction location, allowing for real-time adjustments and direct supervision to meet specific project requirements. Off-site prefabrication refers to manufacturing structural elements in a controlled factory environment, enhancing precision, reducing waste, and accelerating installation timelines. Both methods impact project efficiency, cost management, and quality control within the construction process.

Core Definitions and Key Differences

On-site fabrication involves constructing building components directly at the construction location, allowing customization and adjustments in real-time, whereas off-site prefabrication refers to manufacturing parts in a controlled factory environment before transporting them to the site for assembly. Key differences include quality control, with prefabrication offering consistent standards due to factory conditions, and scheduling flexibility, where on-site fabrication can be more adaptable to design changes but might face weather-related delays. Cost implications also vary; prefabrication often reduces labor and material waste, while on-site work can incur higher expenses due to logistics and longer project timelines.

Historical Evolution in Construction Methods

On-site fabrication dominated early construction due to limited technology and transportation constraints, with craftsmen shaping materials directly at building locations. The Industrial Revolution introduced mechanized processes and modular design, enabling off-site prefabrication to gain prominence by improving efficiency and reducing on-site labor. Modern construction increasingly integrates off-site prefabrication for complex assemblies, reflecting a shift driven by advancements in automation, logistics, and sustainable building practices.

Material Selection and Supply Chain Considerations

On-site fabrication requires materials that are readily available and adaptable to varying environmental conditions, ensuring flexibility in construction schedules. Off-site prefabrication demands high-quality, standardized materials for efficient mass production, emphasizing precise supply chain coordination to minimize disruptions. Effective material selection and streamlined supply logistics directly impact project timelines, cost control, and overall structural integrity in both methods.

Time Efficiency: Project Schedules Compared

On-site fabrication often leads to extended project schedules due to weather delays, labor availability, and coordination challenges, impacting overall time efficiency. Off-site prefabrication streamlines construction timelines by allowing parallel processing of components in controlled environments, reducing on-site assembly time by up to 50%. Prefabrication's ability to minimize disruptions and accelerate project delivery improves schedule adherence and reduces costs associated with delays.

Cost Analysis: Budgeting and Financial Impact

On-site fabrication often incurs higher labor and material handling costs due to extended project timelines and weather dependencies, increasing budget risks. Off-site prefabrication reduces on-site labor expenses and minimizes waste through controlled manufacturing environments, leading to significant cost savings and enhanced budget predictability. Financial analysis reveals prefabrication projects typically see lower overall expenditures and improved return on investment compared to traditional on-site construction methods.

Quality Control and Assurance Standards

On-site fabrication in construction allows for immediate quality control adjustments, but it often faces challenges related to inconsistent environmental conditions and varying skill levels among workers. Off-site prefabrication benefits from controlled factory environments, standardized processes, and rigorous quality assurance protocols, leading to higher precision and reduced defect rates. Implementing ISO 9001 standards in off-site facilities ensures systematic quality management and consistent adherence to construction quality benchmarks.

Safety Implications on Job Sites

On-site fabrication poses higher safety risks due to exposure to variable environmental conditions and direct interaction with heavy machinery and tools, increasing the likelihood of accidents. Off-site prefabrication allows construction components to be manufactured in controlled environments, significantly reducing on-site hazards such as falls, equipment malfunctions, and material handling injuries. Implementing off-site prefabrication can lead to enhanced worker safety, streamlined inspection processes, and minimized exposure to job site risks.

Sustainability and Environmental Outcomes

On-site fabrication often results in higher material waste and increased energy consumption due to variable site conditions, whereas off-site prefabrication improves sustainability by enabling precise material usage and reducing transportation emissions. Off-site processes benefit from controlled factory environments that minimize waste, enhance recycling efforts, and improve energy efficiency during construction. Choosing prefabrication can significantly lower a project's carbon footprint and contribute to greener construction practices.

Future Trends and Industry Innovations

On-site fabrication and off-site prefabrication are evolving with advancements in digital technology, robotics, and sustainable materials, significantly influencing construction efficiency and quality. Industry innovations like modular construction, 3D printing, and Building Information Modeling (BIM) are driving future trends toward more automated, precise, and eco-friendly building processes. The integration of smart manufacturing and IoT-enabled quality control systems is set to transform project timelines and cost management in both fabrication methods.

Related Important Terms

Modular Volumetric Construction

Modular volumetric construction offers significant advantages in off-site prefabrication by enabling entire building modules to be fabricated in controlled factory environments, ensuring higher quality control and reduced on-site labor. On-site fabrication, while providing greater flexibility for customization, often results in longer project timelines and increased exposure to weather delays compared to the streamlined efficiency of modular volumetric units assembled off-site.

Panelized Building Systems

Panelized building systems streamline construction by enabling precise on-site assembly of factory-manufactured wall panels, reducing labor costs and construction waste. Off-site prefabrication enhances quality control and accelerates project timelines, while on-site fabrication allows for flexible customization to accommodate specific site conditions.

Digital Twin Fabrication

Digital twin fabrication enhances both on-site and off-site construction processes by creating precise virtual replicas of building components, enabling real-time monitoring and quality control. Utilizing digital twins in prefabrication optimizes resource allocation and reduces errors, while on-site applications improve installation accuracy and streamline project timelines.

Just-In-Time (JIT) Delivery

Just-In-Time (JIT) delivery enhances off-site prefabrication by synchronizing component manufacturing with project schedules, reducing on-site storage and minimizing material waste. In contrast, on-site fabrication lacks the precision timing of JIT, often resulting in delays and increased inventory costs.

Plug-and-Play Assemblies

Plug-and-play assemblies in off-site prefabrication streamline construction by allowing components to be manufactured under controlled conditions and rapidly installed on-site, reducing labor costs and project timelines. On-site fabrication offers customization and immediate adjustments but typically involves longer installation times and increased exposure to environmental delays.

Prefab MEP Pods

Prefab MEP pods enhance construction efficiency by integrating mechanical, electrical, and plumbing systems off-site, reducing on-site labor and minimizing errors. These modular units streamline project timelines and improve quality control compared to traditional on-site fabrication methods.

Mass Customization

Mass customization in construction leverages off-site prefabrication to efficiently produce highly tailored components using automated processes and standardized modules, reducing on-site labor and waste. On-site fabrication remains essential for unique, complex elements requiring direct adaptation to variable site conditions and immediate design adjustments.

Hybrid Construction Methods

Hybrid construction methods combine on-site fabrication's adaptability with off-site prefabrication's precision and speed, optimizing project timelines and quality control. Integrating modular components manufactured in controlled factory settings with custom on-site adjustments enhances structural efficiency and reduces labor costs.

Lean Prefabrication

Lean prefabrication in construction enhances efficiency by minimizing waste through just-in-time production and standardized processes, whether materials are fabricated on-site or off-site. Off-site prefabrication further optimizes project timelines and quality control by assembling components in controlled factory environments, reducing on-site labor and disruption.

Robotics-Assisted Assembly

Robotics-assisted assembly enhances off-site prefabrication by increasing precision, reducing labor costs, and accelerating production timelines through automated processes in controlled factory environments. On-site fabrication benefits less from robotics due to spatial constraints and variable site conditions, making off-site prefabrication more suitable for scalable, high-quality construction projects.

On-site Fabrication vs Off-site Prefabrication Infographic

industrydif.com

industrydif.com