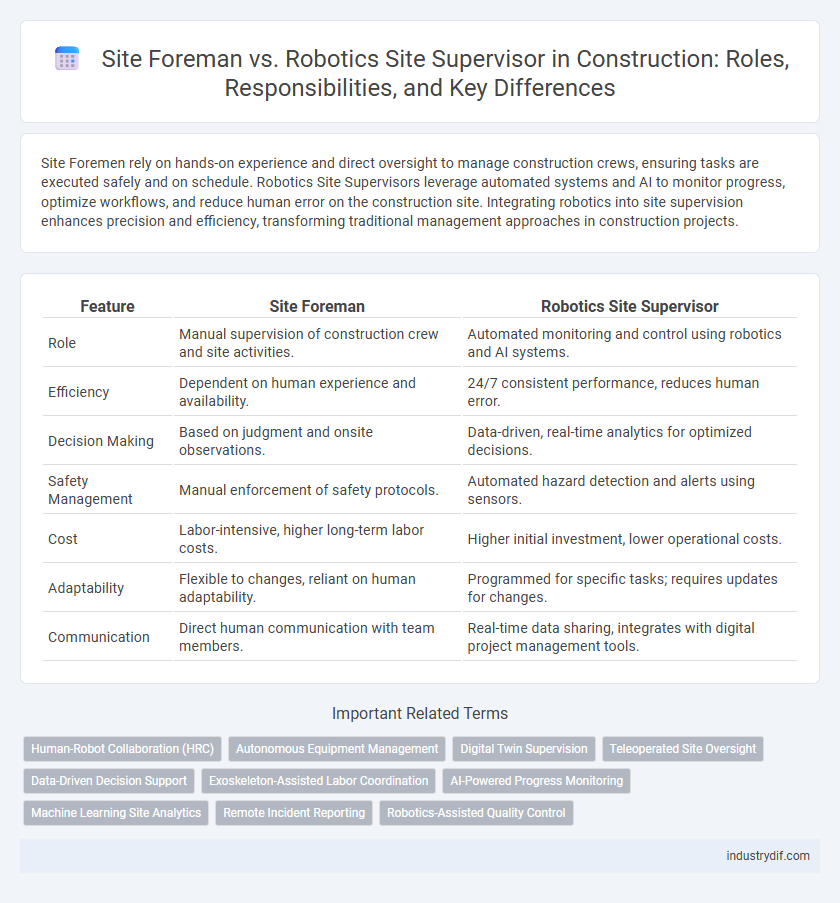

Site Foremen rely on hands-on experience and direct oversight to manage construction crews, ensuring tasks are executed safely and on schedule. Robotics Site Supervisors leverage automated systems and AI to monitor progress, optimize workflows, and reduce human error on the construction site. Integrating robotics into site supervision enhances precision and efficiency, transforming traditional management approaches in construction projects.

Table of Comparison

| Feature | Site Foreman | Robotics Site Supervisor |

|---|---|---|

| Role | Manual supervision of construction crew and site activities. | Automated monitoring and control using robotics and AI systems. |

| Efficiency | Dependent on human experience and availability. | 24/7 consistent performance, reduces human error. |

| Decision Making | Based on judgment and onsite observations. | Data-driven, real-time analytics for optimized decisions. |

| Safety Management | Manual enforcement of safety protocols. | Automated hazard detection and alerts using sensors. |

| Cost | Labor-intensive, higher long-term labor costs. | Higher initial investment, lower operational costs. |

| Adaptability | Flexible to changes, reliant on human adaptability. | Programmed for specific tasks; requires updates for changes. |

| Communication | Direct human communication with team members. | Real-time data sharing, integrates with digital project management tools. |

Role Overview: Site Foreman vs Robotics Site Supervisor

The Site Foreman oversees daily construction activities, managing crews, ensuring safety compliance, and coordinating material deliveries to maintain project timelines. In contrast, the Robotics Site Supervisor integrates automated systems and robotic equipment to optimize site efficiency, monitor machine operations, and troubleshoot technical issues in real-time. Both roles require leadership and project management skills but differ in technological emphasis and operational focus within modern construction environments.

Key Responsibilities in Construction Projects

The Site Foreman oversees daily construction activities, coordinates labor, ensures safety compliance, and manages material delivery to keep the project on schedule. In contrast, the Robotics Site Supervisor monitors automated machinery, programs robotic systems for precision tasks, and integrates technology to enhance efficiency and reduce human error. Both roles play crucial parts in construction project management, with the foreman focusing on human resources and the robotics supervisor leveraging advanced technology to optimize site operations.

Skills and Qualifications Required

A Site Foreman requires extensive experience in construction management, strong leadership skills, and proficiency in reading blueprints and safety regulations, while a Robotics Site Supervisor demands technical expertise in robotics, automation systems, and software diagnostics alongside knowledge of construction workflows. Both roles necessitate excellent communication skills and the ability to coordinate teams effectively, but the Robotics Site Supervisor must also possess advanced problem-solving abilities related to machine operation and maintenance. Certifications such as OSHA for Site Foremen and specialized robotics or automation technology credentials for Robotics Supervisors are critical for ensuring compliance and operational efficiency.

Human Leadership vs Automated Oversight

Site foremen provide critical human leadership by managing on-site teams, making real-time decisions, and adapting to unforeseen challenges with intuition and experience. Robotics site supervisors offer automated oversight through precise monitoring, data collection, and consistent enforcement of safety protocols, minimizing human error. Combining human leadership with robotic automation enhances construction efficiency, safety, and project accountability.

Efficiency and Productivity Comparison

Site foremen traditionally manage on-site labor, coordinating tasks and addressing issues in real-time, but their efficiency depends heavily on experience and communication skills. Robotics site supervisors integrate AI and automation to monitor progress continuously, analyze data for predictive maintenance, and optimize workflow with minimal human error. Studies show robotics supervision can increase productivity by up to 30%, reduce downtime, and improve safety through real-time hazard detection.

Safety Management: Manual vs Automated Approaches

Site foremen rely on manual safety management techniques, conducting regular inspections and enforcing protocols through direct supervision, which allows for immediate human judgment but can be prone to oversight and delays in hazard detection. Robotics site supervisors utilize automated sensors, real-time data analytics, and AI-driven monitoring systems to continuously assess site conditions, promptly identifying safety risks and improving compliance adherence. The combination of human expertise and robotic precision enhances overall construction site safety by reducing accidents and streamlining incident response times.

Communication and Decision Making

Site Foremen rely on direct verbal communication and hands-on decision-making, leveraging their experience to adapt quickly to on-site changes and coordinate workers effectively. Robotics Site Supervisors utilize advanced sensors and AI-driven communication systems to provide real-time data analysis, enabling precise, data-backed decisions that enhance construction site efficiency. Integrating robotics can reduce human error in communication while accelerating decision cycles through continuous monitoring and automated alerts.

Cost Implications in Project Management

Site foremen typically incur higher labor costs due to hourly wages, overtime, and potential human error-related delays, impacting overall project budgets. Robotics site supervisors, while requiring significant initial investment in technology and training, reduce long-term operational expenses by enhancing precision, minimizing rework, and optimizing workflow efficiency. Integrating robotics in construction project management leads to cost savings through decreased downtime and improved resource allocation.

Scalability and Future Trends in Site Supervision

Site Foremen traditionally manage daily tasks and personnel on construction sites, but robotics site supervisors are rapidly enhancing scalability by enabling real-time data collection and automated monitoring across multiple locations simultaneously. Advanced AI-driven robotics integrate IoT sensors and machine learning to optimize workflow efficiency, reduce human error, and support predictive maintenance, positioning them as a cornerstone of future site supervision trends. Adoption of robotic site supervisors accelerates project timelines and facilitates remote management, reflecting a shift towards smart construction environments driven by digital transformation and Industry 4.0 principles.

Choosing the Right Supervisor for Your Construction Site

Selecting the right supervisor for a construction site significantly impacts project efficiency and safety. A Site Foreman offers hands-on experience and immediate responsiveness to on-site challenges, while a Robotics Site Supervisor provides advanced automation, real-time data analysis, and precision in monitoring workflows. Evaluating project scale, complexity, and technological requirements helps determine whether traditional leadership or robotic supervision best enhances productivity and minimizes risk.

Related Important Terms

Human-Robot Collaboration (HRC)

Site Foremen bring critical on-ground decision-making and adaptive problem-solving skills essential for managing complex construction projects, while Robotics Site Supervisors leverage automated systems to enhance precision, safety, and efficiency in repetitive or hazardous tasks. Effective Human-Robot Collaboration (HRC) integrates the site foreman's experiential knowledge with robotic technology, optimizing task allocation, real-time monitoring, and reducing downtime to maximize project productivity and safety compliance.

Autonomous Equipment Management

The Site Foreman typically oversees manual labor and coordinates workflow, while a Robotics Site Supervisor manages autonomous equipment, optimizing operational efficiency through advanced AI-driven task allocation and real-time machine monitoring. Autonomous equipment management reduces human error and increases precision in construction site logistics, enhancing safety and project timelines.

Digital Twin Supervision

Site foremen rely on traditional methods for managing on-site operations, often facing limitations in real-time data accuracy and project efficiency. Robotics site supervisors integrated with Digital Twin technology enable precise virtual replication of construction sites, enhancing real-time monitoring, predictive maintenance, and automated decision-making to optimize resource allocation and reduce delays.

Teleoperated Site Oversight

Teleoperated Site Oversight enhances construction site management by integrating robotics site supervisors with real-time remote control capabilities, increasing precision and safety in hazardous environments. Unlike traditional site foremen, robotics supervisors enable continuous monitoring and data-driven decision-making through advanced sensors and AI, optimizing workflow efficiency and reducing human error.

Data-Driven Decision Support

Site Foremen rely primarily on manual observations and experience-based judgments for decision-making, often leading to slower responses and potential errors. Robotics Site Supervisors leverage real-time sensor data and AI analytics to provide precise, data-driven insights that optimize construction workflows and enhance project efficiency.

Exoskeleton-Assisted Labor Coordination

Site foremen rely on experience and direct supervision to manage labor on construction sites, while robotics site supervisors equipped with exoskeleton-assisted technologies enhance worker endurance and safety by optimizing physical tasks and reducing fatigue. Integration of exoskeletons in labor coordination increases productivity, precision, and ergonomic support, significantly transforming traditional site management practices.

AI-Powered Progress Monitoring

AI-powered progress monitoring enhances robotics site supervisors by providing real-time data analysis and predictive insights, significantly improving accuracy and efficiency compared to traditional site foremen methods. This technology enables automated tracking of construction milestones, reducing human error and enabling proactive decision-making to keep projects on schedule.

Machine Learning Site Analytics

Site Foremen traditionally rely on manual oversight and experience to manage construction activities, whereas Robotics Site Supervisors utilize machine learning site analytics to optimize resource allocation, enhance safety protocols, and predict equipment maintenance needs. Machine learning algorithms analyze real-time site data, improving decision-making accuracy and reducing project delays by identifying patterns and anomalies that are often overlooked in conventional site management.

Remote Incident Reporting

Site foremen rely on manual incident reporting methods that often delay real-time response and accuracy. Robotics site supervisors utilize advanced sensors and AI-driven platforms enabling instant, remote incident reporting with precise data analytics for proactive site management.

Robotics-Assisted Quality Control

Robotics Site Supervisors leverage advanced sensors and AI-driven analytics to perform robotics-assisted quality control, ensuring precision in measurements and defect detection beyond human capability. Site Foremen rely on manual inspections and experience, which can result in variable accuracy and slower defect identification compared to robotics integration.

Site Foreman vs Robotics Site Supervisor Infographic

industrydif.com

industrydif.com