Backhoe loaders offer versatile digging and loading capabilities ideal for standard construction sites, combining a front loader and rear backhoe for efficiency. Amphibious excavators excel in wetland and waterlogged environments, featuring pontoons that enable operation on soft surfaces and shallow water where traditional machinery struggles. Choosing between the two depends on site conditions and project requirements, with backhoe loaders suited for solid ground and amphibious excavators designed for challenging, water-saturated terrains.

Table of Comparison

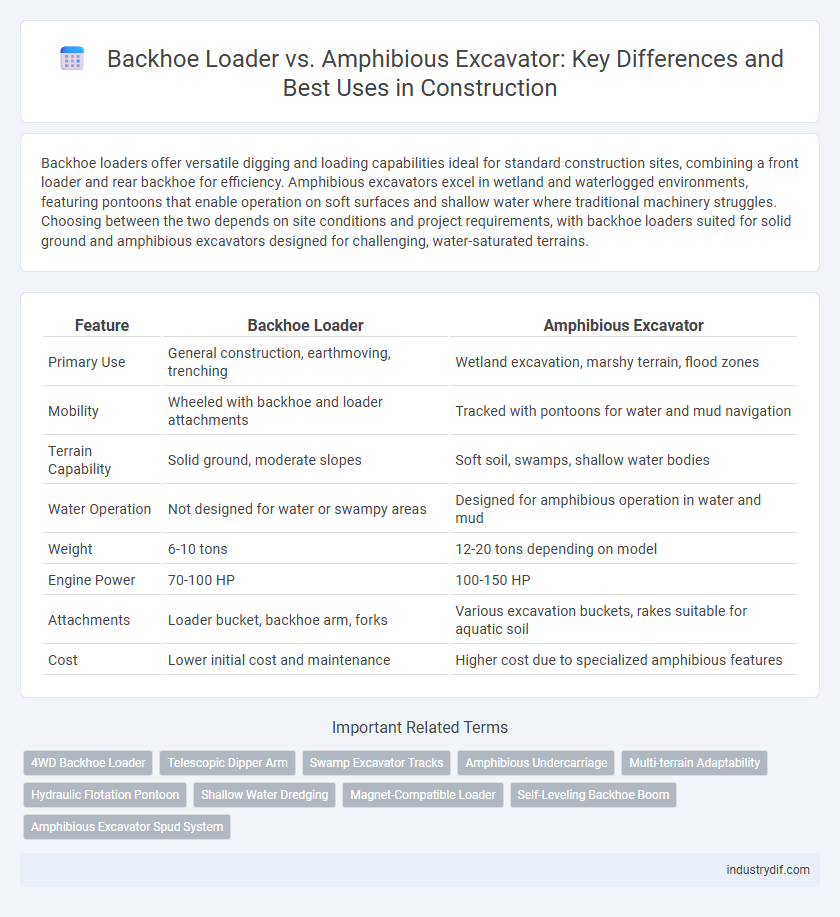

| Feature | Backhoe Loader | Amphibious Excavator |

|---|---|---|

| Primary Use | General construction, earthmoving, trenching | Wetland excavation, marshy terrain, flood zones |

| Mobility | Wheeled with backhoe and loader attachments | Tracked with pontoons for water and mud navigation |

| Terrain Capability | Solid ground, moderate slopes | Soft soil, swamps, shallow water bodies |

| Water Operation | Not designed for water or swampy areas | Designed for amphibious operation in water and mud |

| Weight | 6-10 tons | 12-20 tons depending on model |

| Engine Power | 70-100 HP | 100-150 HP |

| Attachments | Loader bucket, backhoe arm, forks | Various excavation buckets, rakes suitable for aquatic soil |

| Cost | Lower initial cost and maintenance | Higher cost due to specialized amphibious features |

Overview of Backhoe Loaders and Amphibious Excavators

Backhoe loaders are versatile construction machines equipped with a front loader and a rear backhoe, ideal for digging, trenching, and material handling in various terrains. Amphibious excavators feature specialized pontoons, allowing them to operate efficiently in waterlogged or marshy environments such as wetlands, flood zones, and swamps. Both machines offer unique adaptability, with backhoe loaders excelling in general construction tasks and amphibious excavators specializing in aquatic or soft ground excavation.

Key Applications in Construction Projects

Backhoe loaders excel in urban construction projects, offering versatility for digging, trenching, and loading in confined spaces. Amphibious excavators are essential for wetland reclamation, dredging, and flood control, providing superior maneuverability in waterlogged and marshy environments. Selecting between these machines depends on site conditions and specific project requirements such as soil stability and accessibility.

Design and Structural Differences

Backhoe loaders feature a compact design with a front loader bucket and a rear backhoe arm mounted on a wheeled chassis, optimized for versatility in urban and structured environments. Amphibious excavators have a reinforced, buoyant pontoon undercarriage enabling operations in wetlands and waterlogged terrains, with corrosion-resistant materials enhancing durability. Structural differences include the backhoe loader's rigid frame for stability on solid ground, contrasting with the amphibious excavator's flexible, floating foundation tailored for swamp and aquatic conditions.

Performance Capabilities in Varying Terrains

Backhoe loaders excel in urban and moderately rough terrains with versatile digging, loading, and lifting functions, handling compact construction sites efficiently. Amphibious excavators outperform in wetlands, marshes, and flood-prone areas due to their buoyant tracks and ability to operate on waterlogged and unstable grounds. Performance capabilities of amphibious excavators provide superior stability and mobility in soft terrains where conventional backhoe loaders may struggle or become immobilized.

Maneuverability and Accessibility

Backhoe loaders offer superior maneuverability on solid ground due to their compact size and articulated steering, enabling precise operation in confined urban construction sites. Amphibious excavators excel in accessibility to challenging terrains like wetlands and flooded areas, featuring specialized pontoons that allow movement across waterlogged or marshy environments where traditional heavy machinery cannot operate. Choosing between the two depends on project site conditions, with backhoe loaders optimizing efficiency on firm surfaces and amphibious excavators providing critical access in aquatic or soft ground scenarios.

Cost Factors and Investment Considerations

Backhoe loaders generally have lower upfront costs and maintenance expenses compared to amphibious excavators, making them more accessible for standard construction projects. Amphibious excavators, designed for wetland and swampy terrain, require higher initial investment but offer specialized functionality that can reduce project timelines and operational risks in challenging environments. Evaluating project scope and site conditions is crucial to determine the cost-effectiveness and long-term value of each equipment type.

Maintenance Requirements and Longevity

Backhoe loaders require regular maintenance of hydraulic systems, engine components, and tires to ensure optimal performance and extend service life, typically lasting 8-12 years under standard working conditions. Amphibious excavators demand more specialized upkeep, including frequent checks of pontoons for water tightness and corrosion control, which contributes to their longevity of 10-15 years in wetland and marshland environments. Proper maintenance of seals, hydraulic lines, and engine parts in both machines directly impacts their operational efficiency and overall lifespan.

Environmental Impact and Site Disturbance

Backhoe loaders typically cause greater site disturbance due to their heavier tracks and need for stable ground, which can lead to increased soil compaction and erosion. Amphibious excavators, equipped with pontoons, minimize environmental impact by operating efficiently in wetland and waterlogged areas without requiring extensive land clearing or drainage. Choosing amphibious excavators significantly reduces habitat disruption and preserves natural water flow, making them ideal for sensitive ecological sites.

Operator Comfort and Safety Features

Backhoe loaders prioritize operator comfort with ergonomic cabins, adjustable seats, and climate control, reducing fatigue during extended use. Amphibious excavators enhance safety through reinforced, waterproof cabs and elevated operator stations, protecting against harsh wetland conditions and minimizing accident risks. Both machines integrate advanced control systems and visibility enhancements to improve operator precision and situational awareness on complex job sites.

Choosing the Right Equipment for Your Project

Selecting the right equipment involves evaluating terrain and project requirements; backhoe loaders excel in urban construction with versatile digging and loading capabilities on solid ground. Amphibious excavators are specifically designed for wet environments, swampy terrains, and shallow water operations, offering superior stability and mobility where traditional machines struggle. Prioritize machine adaptability, ground conditions, and project scope to maximize efficiency and minimize delays.

Related Important Terms

4WD Backhoe Loader

4WD backhoe loaders provide superior traction and maneuverability on rough and uneven construction sites, enabling efficient digging and loading operations in varied terrains. Unlike amphibious excavators designed for waterlogged environments, 4WD backhoe loaders are optimized for solid ground operations, combining excavation, loading, and material handling capabilities in one versatile machine.

Telescopic Dipper Arm

The telescopic dipper arm on backhoe loaders provides versatile reach and maneuverability for standard excavation and loading tasks, enhancing efficiency in tight urban construction sites. Amphibious excavators with telescopic dipper arms extend operational capability into waterlogged or marshy environments, delivering precise digging performance while maintaining stability on soft or uneven terrain.

Swamp Excavator Tracks

Swamp excavator tracks on amphibious excavators provide superior flotation and maneuverability in wetland and swampy terrains compared to the standard tires or tracks on backhoe loaders. These specialized tracks distribute weight evenly, minimizing ground pressure to prevent sinking while enhancing traction in soft, unstable soils.

Amphibious Undercarriage

The amphibious excavator features a specialized amphibious undercarriage equipped with dual pontoons and wide tracks, enabling superior maneuverability and flotation in swampy, marshy, or waterlogged construction sites. Unlike backhoe loaders, this undercarriage design minimizes ground pressure and prevents sinking, making amphibious excavators ideal for environmental remediation, wetland construction, and flood control projects.

Multi-terrain Adaptability

Backhoe loaders offer versatile multi-terrain capabilities with their robust tires and articulated arms, making them suitable for urban and rough ground operations. Amphibious excavators excel in swampy, marshy, and waterlogged environments due to their specialized pontoons and buoyant design, ensuring efficient excavation in challenging aquatic terrains.

Hydraulic Flotation Pontoon

Hydraulic flotation pontoons on amphibious excavators provide superior buoyancy and stability in waterlogged or swampy construction sites compared to the traditional backhoe loader, allowing efficient excavation in challenging terrains. These pontoons enable amphibious excavators to traverse wetlands, marshes, and shallow water areas where backhoe loaders lack mobility and operational safety.

Shallow Water Dredging

Backhoe loaders excel in shallow water dredging with their versatile digging arm and compact design, allowing efficient sediment removal in confined spaces. Amphibious excavators provide superior maneuverability in wetland and swampy areas, combining tracked mobility and flotation capabilities to maintain stability and minimize environmental impact during shallow water operations.

Magnet-Compatible Loader

Magnet-compatible backhoe loaders enhance construction efficiency by enabling the seamless separation and lifting of ferrous materials during excavation, offering versatility in urban demolition and recycling sites. Amphibious excavators provide superior maneuverability in wetland or flood-prone areas but lack built-in magnetic capabilities, making magnet-compatible backhoe loaders the preferred choice for magnetic separation tasks on diverse terrain.

Self-Leveling Backhoe Boom

The self-leveling backhoe boom in backhoe loaders ensures consistent digging angles and enhanced precision on uneven terrain, improving operational efficiency compared to amphibious excavators, which prioritize flotation and mobility in wetland environments. This feature significantly reduces operator fatigue and material spillage, making backhoe loaders preferable for urban and compact construction sites requiring accurate excavation.

Amphibious Excavator Spud System

The amphibious excavator's spud system provides enhanced stability and mobility in marshy or waterlogged environments, allowing operators to anchor securely while performing excavation tasks in challenging terrains. Unlike backhoe loaders, which are limited to solid ground, the spud system enables amphibious excavators to access and work efficiently in wetlands, swamps, and shallow water areas.

Backhoe Loader vs Amphibious Excavator Infographic

industrydif.com

industrydif.com