Concrete pour involves placing and shaping traditional concrete to form structural elements, requiring careful timing and curing processes to achieve strength and durability. Self-healing concrete incorporates bacteria or chemical agents that automatically fill cracks, extending the lifespan and reducing maintenance needs. Comparing both, self-healing concrete offers enhanced longevity and resilience, while traditional concrete pour remains the standard for straightforward, cost-effective construction tasks.

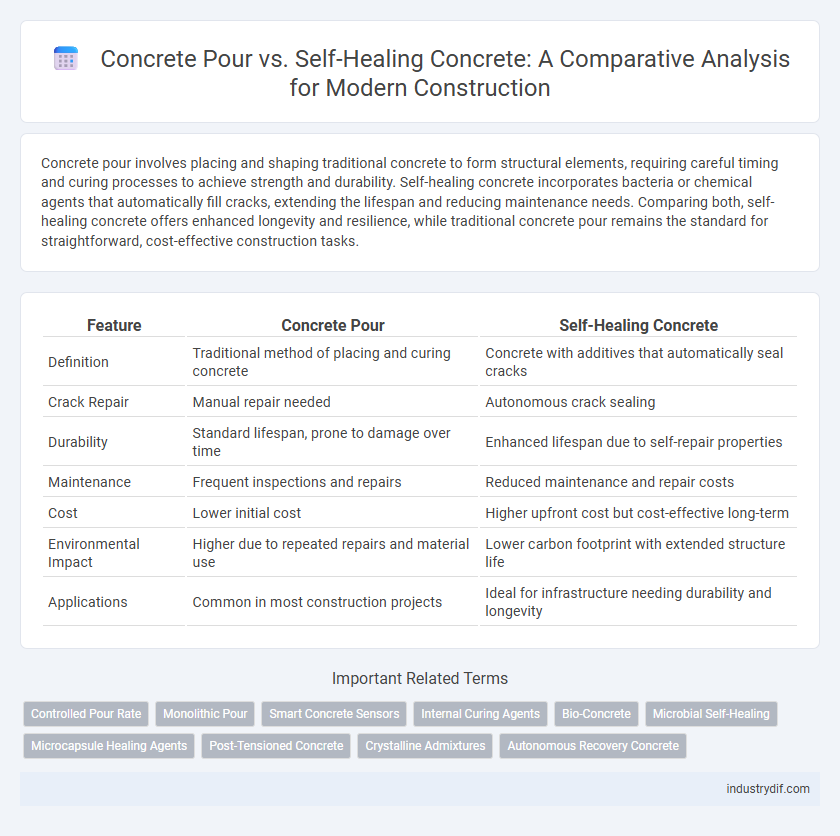

Table of Comparison

| Feature | Concrete Pour | Self-Healing Concrete |

|---|---|---|

| Definition | Traditional method of placing and curing concrete | Concrete with additives that automatically seal cracks |

| Crack Repair | Manual repair needed | Autonomous crack sealing |

| Durability | Standard lifespan, prone to damage over time | Enhanced lifespan due to self-repair properties |

| Maintenance | Frequent inspections and repairs | Reduced maintenance and repair costs |

| Cost | Lower initial cost | Higher upfront cost but cost-effective long-term |

| Environmental Impact | Higher due to repeated repairs and material use | Lower carbon footprint with extended structure life |

| Applications | Common in most construction projects | Ideal for infrastructure needing durability and longevity |

Introduction to Concrete Pour and Self-Healing Concrete

Concrete pour involves the process of placing, compacting, and curing fresh concrete into formwork to create structural elements such as slabs, beams, and columns. Self-healing concrete incorporates advanced materials like bacteria or chemical agents that react with moisture and oxygen to autonomously repair cracks, enhancing durability and reducing maintenance costs. The integration of self-healing technology represents a significant innovation in construction materials, aiming to extend the lifespan of concrete structures while minimizing human intervention.

Traditional Concrete Pour: Process and Applications

Traditional concrete pour involves mixing cement, water, and aggregates before placing the mixture into forms where it hardens through hydration, providing structural strength for foundations, slabs, and beams. This method requires precise water-to-cement ratios and curing times to ensure durability, often involving manual labor and equipment such as mixers, vibrators, and curing blankets. Widely used in residential, commercial, and infrastructure projects, traditional concrete pours remain standard due to their proven reliability and cost-effectiveness in diverse construction applications.

Overview of Self-Healing Concrete Technology

Self-healing concrete technology incorporates embedded microcapsules or bacteria that activate upon cracking, autonomously repairing fissures and significantly extending the lifespan of structures. This innovative material reduces maintenance costs and enhances durability compared to traditional concrete pour methods, which require manual repairs for damage. Advancements in self-healing concrete optimize structural integrity and promote sustainable construction practices by minimizing carbon footprint and resource consumption.

Strength and Durability Comparison

Concrete pour techniques traditionally emphasize immediate compressive strength and uniform curing to ensure structural integrity, often requiring significant maintenance over time due to micro-cracking and wear. Self-healing concrete incorporates microcapsules or bacteria that activate upon damage, significantly enhancing durability by autonomously sealing cracks, reducing permeability, and increasing lifespan. Studies show self-healing concrete can achieve up to 20% greater tensile strength retention and extend structural service life by 30% compared to conventional concrete pours.

Cost Implications and Economic Benefits

Concrete pour involves significant labor, material, and equipment expenses, with recurring costs due to maintenance and repair over time. Self-healing concrete reduces long-term expenses by automatically repairing micro-cracks, minimizing structural damage and maintenance frequency. Investing in self-healing concrete offers economic benefits through extended infrastructure lifespan and decreased lifecycle costs despite higher initial material prices.

Sustainability and Environmental Impact

Concrete pour techniques significantly influence sustainability by determining resource efficiency, waste generation, and carbon emissions, with traditional methods often leading to high environmental footprints due to excessive material usage and energy-intensive processes. Self-healing concrete enhances environmental performance by reducing the need for repairs and replacements, thereby lowering lifecycle emissions, conserving raw materials, and minimizing construction waste. This innovative material supports sustainable construction goals by extending structure durability and promoting resource conservation through autonomous crack repair mechanisms.

Maintenance and Lifecycle Performance

Concrete pour requires regular maintenance and inspection to address cracking, spalling, and weathering, which can lead to costly repairs and shorten the structure's lifecycle performance. Self-healing concrete incorporates microcapsules or bacteria that autonomously seal cracks, significantly reducing maintenance needs and extending the durability and lifespan of concrete structures. Lifecycle performance of self-healing concrete outperforms traditional concrete pours by minimizing degradation and enhancing long-term structural integrity.

Industry Adoption and Case Studies

Concrete pour remains the standard method in construction due to its proven strength and widespread industry adoption, with case studies highlighting successful large-scale projects like bridges and commercial buildings. Self-healing concrete, an emerging technology, shows promising durability improvements by autonomously repairing cracks, demonstrated in pilot projects such as tunnel linings and marine structures. Industry uptake of self-healing concrete is growing gradually as cost and scalability challenges are addressed through ongoing research and real-world applications.

Challenges and Limitations in Implementation

Concrete pour faces challenges such as labor intensity, curing time variability, and vulnerability to early-stage cracking, leading to structural weaknesses and increased maintenance costs. Self-healing concrete, while promising reduced repair frequency and extended lifespan, encounters limitations including high production costs, inconsistent healing performance under diverse environmental conditions, and limited scalability in large-scale construction projects. Implementation hurdles also stem from lack of standardized testing protocols and insufficient long-term durability data critical for regulatory approvals.

Future Trends in Concrete Innovations

Future trends in concrete innovations emphasize integrating self-healing concrete to enhance durability and reduce maintenance costs compared to traditional concrete pour methods. Advances in microencapsulation technologies enable concrete to autonomously repair cracks, extending structural lifespan and minimizing environmental impact. Research in nanomaterials and bio-based agents drives the development of smart concrete with improved sustainability and resilience in infrastructure projects.

Related Important Terms

Controlled Pour Rate

Controlled pour rate in concrete pouring ensures uniform setting and reduces the risk of cold joints, enhancing structural integrity. Self-healing concrete optimizes this process by promoting autonomous crack repair, reducing maintenance and extending the lifespan of construction projects.

Monolithic Pour

Monolithic pour in traditional concrete involves a continuous, seamless placement creating a strong, uniform structure but is prone to cracking over time due to shrinkage and environmental stress. Self-healing concrete integrates microcapsules or bacteria that activate upon cracking, autonomously repairing damage to extend structural durability and reduce maintenance costs.

Smart Concrete Sensors

Smart concrete sensors embedded within traditional concrete pours enable real-time monitoring of structural integrity, detecting cracks and stress before visible damage occurs. In contrast, self-healing concrete incorporates microcapsules or bacteria that activate upon damage, but integrating smart sensors enhances its durability by providing precise data for timely maintenance interventions.

Internal Curing Agents

Internal curing agents in self-healing concrete enhance hydration by gradually releasing moisture within the mix, reducing shrinkage and cracking compared to traditional concrete pour methods. This technology improves durability and lifespan by promoting continuous cement hydration, minimizing the need for external curing and repair.

Bio-Concrete

Bio-concrete, a form of self-healing concrete, incorporates bacteria that produce limestone to fill cracks autonomously, reducing maintenance and extending the lifespan of structures compared to traditional concrete pour methods. This innovative material addresses micro-cracks actively, enhancing durability and sustainability in construction projects by minimizing repair costs and environmental impact.

Microbial Self-Healing

Microbial self-healing concrete utilizes bacteria embedded in the material to precipitate calcium carbonate, effectively sealing cracks and enhancing durability without the need for traditional concrete pouring and frequent repairs. This innovative approach reduces maintenance costs and extends the lifespan of structures by promoting autonomous crack remediation at a microscopic level.

Microcapsule Healing Agents

Microcapsule healing agents in self-healing concrete enable autonomous crack repair by releasing healing compounds upon damage, significantly extending the material's durability compared to traditional concrete pour methods that lack intrinsic repair mechanisms. This innovative approach reduces maintenance costs and enhances structural integrity by preventing microcrack propagation before they become critical.

Post-Tensioned Concrete

Post-tensioned concrete relies on precise concrete pour techniques to ensure proper tensioning and structural integrity, whereas self-healing concrete integrates microcapsules or bacteria to autonomously repair cracks, enhancing durability and reducing maintenance. Advances in self-healing materials tailored for post-tensioned systems address common issues such as microcracking and corrosion of tendons, significantly extending the lifespan of structures.

Crystalline Admixtures

Crystalline admixtures enhance conventional concrete by promoting self-healing through the formation of insoluble crystals that block micro-cracks and prevent water ingress, significantly extending structural durability compared to traditional concrete pours. This innovative technology reduces maintenance costs and increases the lifespan of concrete infrastructure by autonomously sealing cracks, making it ideal for critical construction applications.

Autonomous Recovery Concrete

Autonomous recovery concrete leverages advanced polymer-based microcapsules that release healing agents upon crack formation, enabling the material to self-repair without external intervention. This innovative technology enhances durability and reduces maintenance costs compared to traditional concrete pours, which require manual repairs and periodic inspections.

Concrete Pour vs Self-Healing Concrete Infographic

industrydif.com

industrydif.com