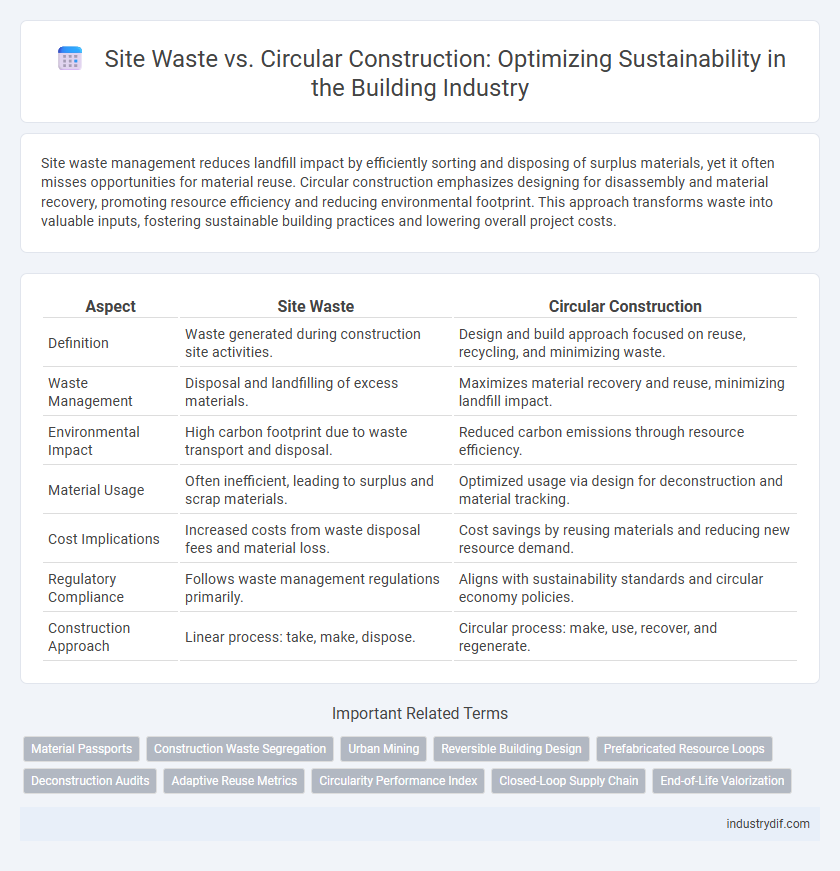

Site waste management reduces landfill impact by efficiently sorting and disposing of surplus materials, yet it often misses opportunities for material reuse. Circular construction emphasizes designing for disassembly and material recovery, promoting resource efficiency and reducing environmental footprint. This approach transforms waste into valuable inputs, fostering sustainable building practices and lowering overall project costs.

Table of Comparison

| Aspect | Site Waste | Circular Construction |

|---|---|---|

| Definition | Waste generated during construction site activities. | Design and build approach focused on reuse, recycling, and minimizing waste. |

| Waste Management | Disposal and landfilling of excess materials. | Maximizes material recovery and reuse, minimizing landfill impact. |

| Environmental Impact | High carbon footprint due to waste transport and disposal. | Reduced carbon emissions through resource efficiency. |

| Material Usage | Often inefficient, leading to surplus and scrap materials. | Optimized usage via design for deconstruction and material tracking. |

| Cost Implications | Increased costs from waste disposal fees and material loss. | Cost savings by reusing materials and reducing new resource demand. |

| Regulatory Compliance | Follows waste management regulations primarily. | Aligns with sustainability standards and circular economy policies. |

| Construction Approach | Linear process: take, make, dispose. | Circular process: make, use, recover, and regenerate. |

Defining Site Waste in Construction

Site waste in construction encompasses all materials, debris, and by-products generated during building activities that are discarded or not repurposed. This includes surplus concrete, packaging, timber off-cuts, and unused bricks, which contribute significantly to environmental pollution and increased project costs. Effective management and reduction of site waste are crucial for advancing sustainable construction practices and minimizing resource depletion.

Understanding Circular Construction Principles

Circular construction principles prioritize minimizing site waste by designing buildings for material reuse, efficient resource management, and end-of-life deconstruction. Emphasizing closed-loop systems, these principles reduce landfill dependence through recycling and repurposing of construction materials on-site. Integrating modular design and durable materials supports sustainable construction practices that align with environmental and economic goals.

Key Differences Between Site Waste and Circular Construction

Site waste management focuses on minimizing and properly disposing of materials discarded during construction processes, aiming to reduce landfill usage and regulatory non-compliance. Circular construction emphasizes designing and executing building projects with the reuse, recycling, and regeneration of materials at their core, promoting sustainability through closed-loop resource cycles. Key differences lie in site waste targeting waste reduction post-production, while circular construction integrates waste prevention and material lifecycle extension from project inception.

Common Sources of Construction Site Waste

Common sources of construction site waste include excess materials such as concrete, wood, and metal offcuts, packaging debris, and leftover insulation. Inefficient material handling and over-ordering contribute significantly to waste generation on site. Circular construction emphasizes reducing these wastes by promoting material reuse, recycling, and designing for disassembly.

Circular Construction: Materials Reuse and Recycling

Circular construction prioritizes minimizing waste by incorporating materials reuse and recycling directly on-site, reducing the demand for new raw materials and lowering environmental impact. Techniques include deconstructing existing structures to salvage bricks, metals, and timber for repurposing, alongside sorting waste streams to separate recyclable materials such as concrete and plastics for processing. This approach supports sustainable building practices, contributes to cost savings, and aligns with regulatory frameworks aimed at reducing landfill waste in the construction industry.

Economic Impacts of Site Waste vs Circular Construction

Site waste in construction often leads to increased disposal costs, resource inefficiency, and financial losses due to material overordering and landfill fees. Circular construction minimizes these economic impacts by promoting the reuse and recycling of materials, lowering procurement costs and reducing waste management expenses. Implementing circular practices enhances profitability through resource optimization and supports long-term cost savings by decreasing reliance on virgin materials.

Environmental Benefits of Circular Construction

Circular construction significantly reduces landfill waste by promoting the reuse and recycling of materials, minimizing raw material extraction and associated environmental degradation. This approach lowers greenhouse gas emissions through efficient resource management and reduces energy consumption compared to traditional site waste disposal methods. Emphasizing material circularity enhances sustainability in construction projects, contributing to a greener built environment and conservation of natural resources.

Challenges in Reducing Site Waste

Reducing site waste in construction faces significant challenges such as inaccurate material estimation, limited on-site recycling facilities, and fragmented supply chains leading to excess inventory. Circular construction demands an integrated approach that prioritizes design for disassembly, material reuse, and resource efficiency, yet existing project timelines and cost constraints often hinder its full implementation. Overcoming these barriers requires enhanced collaboration among stakeholders, investment in advanced waste tracking technologies, and adoption of regulatory frameworks supporting circular economy principles.

Best Practices for Transitioning to Circular Construction

Minimizing site waste through efficient resource management and accurate material quantification lays a strong foundation for adopting circular construction methods. Implementing on-site segregation and recycling protocols ensures valuable materials are recovered and reused, reducing landfill dependency. Integrating digital tools like Building Information Modeling (BIM) facilitates precise tracking of materials, enabling seamless transitions from linear waste processes to circular material flows.

Future Trends: Embracing Circularity in the Construction Industry

The construction industry is shifting from traditional site waste management to adopting circular construction principles that prioritize resource efficiency and material reuse. Emerging technologies like digital twins and BIM enable precise waste tracking and optimized material lifecycle management, reducing environmental impact. Future trends emphasize zero-waste goals, closed-loop supply chains, and innovative recycling methods to support sustainable urban development and regulatory compliance.

Related Important Terms

Material Passports

Material Passports enable detailed documentation of construction materials, facilitating efficient reuse and recycling in Circular Construction to minimize site waste. By providing transparent data on the composition and lifecycle of materials, Material Passports promote sustainable resource management and reduce landfill impact on construction sites.

Construction Waste Segregation

Construction waste segregation improves resource recovery by separating materials such as concrete, wood, metals, and plastics onsite, reducing landfill disposal by up to 50%. Circular construction leverages segregated waste to recycle and reuse materials efficiently, minimizing raw material extraction and promoting sustainable building practices.

Urban Mining

Urban mining maximizes resource efficiency by reclaiming valuable materials from construction and demolition waste, reducing the volume of site waste sent to landfill. Circular construction integrates urban mining practices to promote material reuse, lower environmental impact, and support sustainable urban development.

Reversible Building Design

Reversible building design minimizes site waste by enabling components to be easily disassembled and reused, thus supporting circular construction principles that prioritize resource efficiency and material recovery. Implementing modular systems and standardized connections facilitates adaptability and extends building life cycles, significantly reducing landfill contributions and environmental impact.

Prefabricated Resource Loops

Prefabricated resource loops in circular construction minimize site waste by enabling off-site manufacturing of components with precise material usage and reduced excess. This approach streamlines material flow, promotes recycling of prefabricated elements, and enhances sustainability throughout the construction lifecycle.

Deconstruction Audits

Deconstruction audits play a critical role in circular construction by systematically assessing materials for reuse, minimizing site waste through detailed inventory and recovery plans. This approach contrasts with traditional site waste management, which often prioritizes disposal over resource reclamation.

Adaptive Reuse Metrics

Adaptive reuse metrics evaluate the reduction of site waste by measuring the extent to which existing structures are retained and repurposed, minimizing demolition debris and new material consumption. These metrics include embodied carbon savings, waste diversion rates, and the percentage of reused building components, promoting circular construction principles that prioritize resource efficiency and environmental impact reduction.

Circularity Performance Index

The Circularity Performance Index measures the efficiency of resource use and waste reduction in construction projects, emphasizing the reuse and recycling of materials to minimize site waste. By quantifying circularity, it enables comparison between traditional Linear Site Waste approaches and innovative Circular Construction methods, promoting sustainable building practices.

Closed-Loop Supply Chain

Site waste management prioritizes minimizing landfill disposal through sorting and recycling, whereas circular construction emphasizes a closed-loop supply chain that continuously repurposes materials within the building lifecycle. Implementing closed-loop systems enhances resource efficiency by returning deconstructed materials directly into new construction processes, reducing raw material extraction and environmental impact.

End-of-Life Valorization

End-of-life valorization in construction prioritizes the recovery and recycling of materials from demolition and deconstruction, significantly reducing site waste by diverting debris from landfills. Circular construction enhances sustainability by repurposing reclaimed resources, such as concrete, steel, and timber, into new project components, thereby extending material life cycles and minimizing environmental impact.

Site Waste vs Circular Construction Infographic

industrydif.com

industrydif.com