Prefabrication involves manufacturing building components in a controlled factory environment, then transporting them to the construction site for assembly, ensuring precision and reduced onsite labor. Offsite modular construction goes further by producing entire modules or sections of a building offsite, which are then delivered and assembled onsite, significantly accelerating project timelines and minimizing site disruption. Both methods enhance quality control and reduce waste compared to traditional construction but differ in the scale and speed of assembly.

Table of Comparison

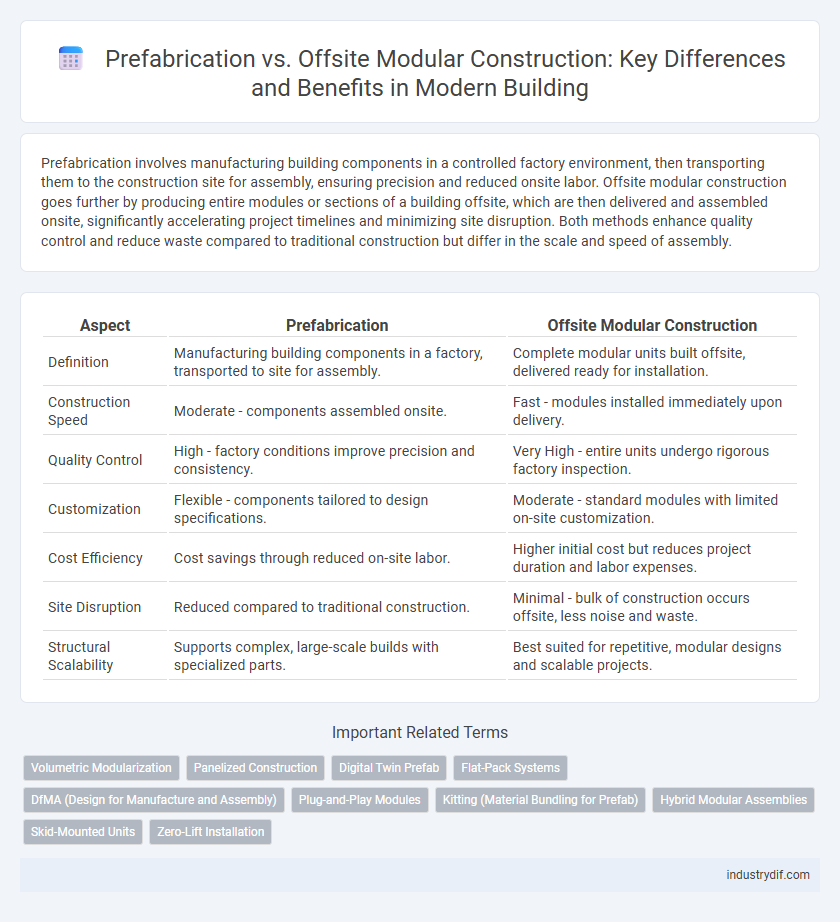

| Aspect | Prefabrication | Offsite Modular Construction |

|---|---|---|

| Definition | Manufacturing building components in a factory, transported to site for assembly. | Complete modular units built offsite, delivered ready for installation. |

| Construction Speed | Moderate - components assembled onsite. | Fast - modules installed immediately upon delivery. |

| Quality Control | High - factory conditions improve precision and consistency. | Very High - entire units undergo rigorous factory inspection. |

| Customization | Flexible - components tailored to design specifications. | Moderate - standard modules with limited on-site customization. |

| Cost Efficiency | Cost savings through reduced on-site labor. | Higher initial cost but reduces project duration and labor expenses. |

| Site Disruption | Reduced compared to traditional construction. | Minimal - bulk of construction occurs offsite, less noise and waste. |

| Structural Scalability | Supports complex, large-scale builds with specialized parts. | Best suited for repetitive, modular designs and scalable projects. |

Definition and Key Differences

Prefabrication involves manufacturing building components in a factory setting before transporting them to the construction site for assembly, whereas offsite modular construction entails creating entire modules or sections of a building offsite, which are then transported and installed on location. Key differences include the scale and complexity of production, with prefabrication typically focusing on individual elements like walls or panels, while modular construction delivers complete, fully finished units. This distinction affects project timelines, cost-efficiency, and quality control in construction processes.

Historical Evolution of Prefabrication and Modular Construction

Prefabrication in construction traces back to the early 20th century with the advent of mass-produced housing units during the industrial revolution, significantly reducing onsite labor and construction time. Offsite modular construction evolved from these principles by integrating advanced manufacturing techniques and digital design tools, allowing entire building modules to be produced in factory settings before assembly onsite. The historical evolution highlights a shift from simple prefab components to fully integrated modular units, driven by technological innovation and demand for efficient, sustainable building solutions.

Core Components and Technologies

Prefabrication involves manufacturing core components such as walls, floors, and roof panels in controlled factory settings, utilizing advanced CNC machinery and automated cutting technologies to ensure precision and quality. Offsite modular construction integrates these prefabricated components into complete volumetric modules equipped with pre-installed electrical, plumbing, and HVAC systems, leveraging BIM (Building Information Modeling) software for seamless design coordination and efficient assembly. Both methods enhance construction speed, reduce waste, and improve consistency, but modular construction offers higher complexity integration and faster onsite installation.

Design Flexibility and Customization

Prefabrication offers moderate design flexibility through standardized components that speed up construction, but customization options are often limited due to factory constraints. Offsite modular construction provides enhanced design flexibility by allowing fully customized modules to be fabricated simultaneously, accommodating complex architectural features and client specifications. Both methods reduce on-site construction time, but modular construction excels in adapting designs to unique project requirements without compromising quality.

Speed and Efficiency in Project Delivery

Prefabrication accelerates project delivery by manufacturing components in controlled factory settings, reducing on-site construction time and minimizing weather-related delays. Offsite modular construction enhances efficiency through the simultaneous site preparation and module fabrication, enabling faster assembly and early project completion. Both methods improve overall productivity by streamlining workflows and reducing labor costs, but modular construction offers greater flexibility for complex designs and large-scale projects.

Cost Implications and Budget Considerations

Prefabrication typically reduces labor costs by allowing components to be manufactured in controlled factory settings, minimizing onsite construction time and associated expenses. Offsite modular construction often involves higher initial design and transportation costs but can lead to significant overall budget savings through faster project completion and reduced site disruption. Evaluating project scale, timeline, and logistical factors is essential to optimize cost efficiency between prefabrication and modular methods.

Quality Control and Standardization

Prefabrication involves manufacturing building components in a controlled factory setting, ensuring consistent quality control through standardized processes and materials. Offsite modular construction extends this approach by assembling complete modules offsite with rigorous quality checks before transportation, further enhancing standardization and reducing onsite variability. Both methods improve project efficiency and minimize defects by leveraging factory precision and repeatable production standards.

Sustainability and Environmental Impact

Prefabrication and offsite modular construction significantly reduce waste generation by enabling precise material cutting and recycling within controlled factory environments, leading to lower landfill contributions. These methods enhance energy efficiency through minimized onsite equipment use and shorter construction timelines, resulting in decreased greenhouse gas emissions. Sustainable sourcing of materials and improved building performance also contribute to reducing the overall environmental footprint of construction projects.

Common Applications and Use Cases

Prefabrication is commonly applied in residential housing, commercial buildings, and infrastructure projects where components like walls, floors, and roof sections are manufactured offsite for quick assembly onsite. Offsite modular construction is particularly suited for multifamily housing, hotels, healthcare facilities, and student accommodations, allowing entire modules or rooms to be constructed in factories before shipment. Both methods streamline construction timelines, improve quality control, and reduce onsite labor, but modular construction provides higher flexibility for complex, multi-story developments.

Future Trends and Innovations

Advancements in digital technologies such as BIM and IoT are driving the future of prefabrication and offsite modular construction, enabling greater precision, efficiency, and real-time project monitoring. Sustainable materials and energy-efficient designs are increasingly integrated into modular units, reflecting the construction industry's shift towards environmental responsibility. The rise of automated manufacturing processes and robotics further accelerates production speed and quality control in both prefabrication and offsite modular construction methods.

Related Important Terms

Volumetric Modularization

Volumetric modularization in offsite modular construction involves manufacturing fully built, three-dimensional units in controlled factory settings, enhancing precision and reducing on-site labor and construction time. Prefabrication typically refers to producing components or assemblies, but volumetric modularization offers greater efficiency by delivering pre-finished, functional modules that accelerate project timelines and minimize disruption.

Panelized Construction

Panelized construction, a subset of prefabrication, involves manufacturing wall, floor, and roof panels in a controlled factory environment before transporting them to the construction site for assembly. This method enhances precision, reduces on-site labor, and accelerates project timelines compared to traditional offsite modular construction, which delivers fully assembled modules.

Digital Twin Prefab

Digital Twin Prefab in construction leverages detailed digital replicas to enhance precision in both prefabrication and offsite modular construction, enabling real-time monitoring and optimization of building components before physical assembly. This integration reduces errors, shortens project timelines, and improves overall quality by synchronizing virtual models with actual production and installation workflows.

Flat-Pack Systems

Flat-pack systems in prefabrication enable rapid assembly through pre-cut, standardized components, reducing onsite labor and material waste. Offsite modular construction utilizes these flat-pack units for scalable, customizable buildings with enhanced quality control and minimized construction timelines.

DfMA (Design for Manufacture and Assembly)

DfMA drives efficiency in both prefabrication and offsite modular construction by optimizing design elements for streamlined manufacturing and rapid on-site assembly. Offsite modular construction leverages DfMA principles more extensively, enabling complete building modules to be fabricated under controlled factory conditions, significantly reducing construction time and minimizing on-site labor compared to traditional prefabrication methods.

Plug-and-Play Modules

Plug-and-play modules in offsite modular construction offer streamlined assembly and reduced onsite labor compared to traditional prefabrication methods, enhancing project efficiency and minimizing construction timelines. These fully integrated units come pre-wired and pre-plumbed, facilitating faster installation while maintaining high quality control standards in factory environments.

Kitting (Material Bundling for Prefab)

Kitting in prefabrication involves organizing and bundling materials for specific construction tasks, enhancing efficiency by reducing onsite handling and minimizing delays. Offsite modular construction leverages kitting to streamline assembly processes, ensuring precise delivery of components and accelerating overall project timelines.

Hybrid Modular Assemblies

Hybrid modular assemblies combine the precision of prefabrication with the efficiency of offsite modular construction, allowing for complex building components to be manufactured in controlled environments before onsite integration. This method reduces construction time, minimizes waste, and enhances quality control by leveraging both factory-built elements and traditional onsite assembly techniques.

Skid-Mounted Units

Skid-mounted units in prefabrication allow for efficient assembly and transportation of modular components, minimizing on-site labor and reducing construction timelines. These units, designed for easy relocation and integration, enhance scalability and adaptability in offsite modular construction projects.

Zero-Lift Installation

Zero-lift installation in offsite modular construction significantly reduces onsite labor and crane requirements by enabling modules to be assembled at ground level and then slid or rolled into place, enhancing safety and efficiency compared to traditional prefabrication methods that often rely on heavy lifting equipment. This approach accelerates project timelines and minimizes disruptions, making it ideal for urban construction sites with limited space and strict scheduling constraints.

Prefabrication vs Offsite Modular Construction Infographic

industrydif.com

industrydif.com