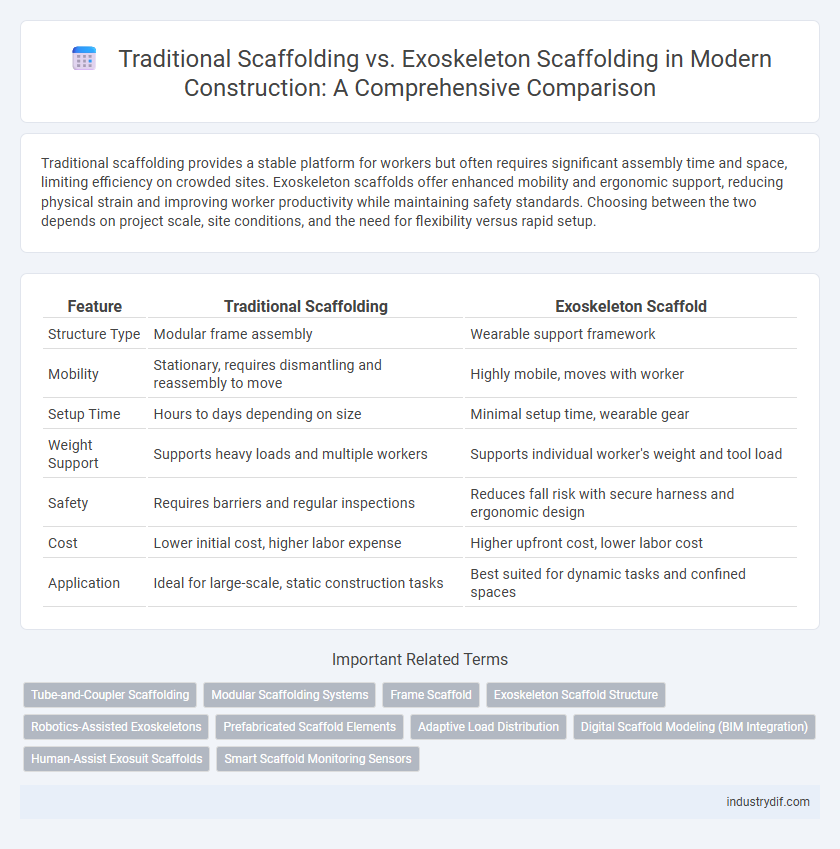

Traditional scaffolding provides a stable platform for workers but often requires significant assembly time and space, limiting efficiency on crowded sites. Exoskeleton scaffolds offer enhanced mobility and ergonomic support, reducing physical strain and improving worker productivity while maintaining safety standards. Choosing between the two depends on project scale, site conditions, and the need for flexibility versus rapid setup.

Table of Comparison

| Feature | Traditional Scaffolding | Exoskeleton Scaffold |

|---|---|---|

| Structure Type | Modular frame assembly | Wearable support framework |

| Mobility | Stationary, requires dismantling and reassembly to move | Highly mobile, moves with worker |

| Setup Time | Hours to days depending on size | Minimal setup time, wearable gear |

| Weight Support | Supports heavy loads and multiple workers | Supports individual worker's weight and tool load |

| Safety | Requires barriers and regular inspections | Reduces fall risk with secure harness and ergonomic design |

| Cost | Lower initial cost, higher labor expense | Higher upfront cost, lower labor cost |

| Application | Ideal for large-scale, static construction tasks | Best suited for dynamic tasks and confined spaces |

Overview of Traditional Scaffolding and Exoskeleton Scaffold

Traditional scaffolding consists of a temporary framework made from metal tubes and wooden planks, offering support for workers and materials during construction. Exoskeleton scaffolds integrate advanced wearable technology, providing enhanced mobility and load-bearing capacity directly to construction workers, reducing reliance on built structures. Both systems improve safety and efficiency, with traditional scaffolding emphasizing modular assembly and exoskeletons focusing on individual support and ergonomic benefits.

Historical Evolution of Scaffolding Methods

Traditional scaffolding, rooted in ancient civilizations such as Egypt and Rome, primarily utilized timber and metal poles to create temporary structures for construction access. The historical evolution led to the development of exoskeleton scaffolds, integrating advanced materials like aluminum and steel alloys to enhance strength, flexibility, and worker safety. Modern exoskeleton scaffolding systems incorporate ergonomic design and modular components, revolutionizing construction site efficiency compared to conventional timber frameworks.

Core Materials and Design Differences

Traditional scaffolding primarily uses steel or aluminum tubes connected by couplers, emphasizing modularity and ease of assembly, while exoskeleton scaffolds utilize advanced composite materials and integrated frameworks for enhanced strength and reduced weight. The design of traditional scaffolding relies on repetitive, vertical and horizontal support structures, whereas exoskeleton scaffolds feature ergonomic, form-fitting frameworks that distribute loads more efficiently and allow greater flexibility in complex architectural projects. These core material and design differences result in exoskeleton scaffolds offering superior durability and safety in dynamic construction environments compared to conventional scaffolding systems.

Installation Process Comparison

Traditional scaffolding installation involves assembling multiple modular components manually, requiring extensive labor and time on-site, often extending project schedules due to complexity and safety checks. Exoskeleton scaffolds feature prefabricated, lightweight frames that streamline the setup process, significantly reducing labor hours and enhancing worker safety by minimizing the need for climbing and balance. The efficiency of exoskeleton scaffold installation supports faster project turnover, making it a preferred choice for modern construction sites seeking to optimize productivity and minimize downtime.

Structural Stability and Load Capacity

Traditional scaffolding relies on interconnected steel or aluminum tubes and couplers, providing flexible configurations but limited load capacity and structural stability under dynamic stresses. Exoskeleton scaffolds incorporate rigid frame designs with integrated load-bearing components, significantly enhancing stability and supporting heavier loads for complex construction tasks. The superior structural integrity of exoskeleton scaffolds reduces risk of collapse and improves safety margins on high-rise projects.

Safety Standards and Worker Protection

Traditional scaffolding relies on rigid metal frames that must be securely anchored and regularly inspected to meet OSHA safety standards, ensuring stability and minimizing fall hazards. Exoskeleton scaffolds integrate wearable support systems with structural platforms, enhancing worker mobility while providing additional fall protection mechanisms compliant with ANSI guidelines. Both methods require strict adherence to safety protocols, but exoskeleton scaffolds offer advanced ergonomic benefits that reduce strain-related injuries and improve overall worker safety on construction sites.

Cost Analysis: Initial Investment and Maintenance

Traditional scaffolding requires a lower initial investment compared to exoskeleton scaffolds, which involve higher upfront costs due to advanced materials and technology integration. Maintenance expenses for traditional scaffolding tend to be higher over time because of frequent repairs and labor-intensive upkeep, whereas exoskeleton scaffolds benefit from durable construction and modular components that reduce long-term maintenance costs. Evaluating total cost of ownership reveals that despite the higher initial expenditure, exoskeleton scaffolds can offer better cost efficiency through improved durability and lower maintenance frequency in extensive construction projects.

Flexibility and Adaptability on Site

Traditional scaffolding offers basic flexibility but requires significant manual assembly and adjustment, limiting rapid adaptation to complex or changing site conditions. Exoskeleton scaffolds provide enhanced adaptability with modular components and integrated support systems, enabling quicker configuration changes and improved access to difficult areas. This advanced flexibility reduces downtime and increases safety on dynamic construction sites.

Environmental Impact and Sustainability

Traditional scaffolding relies heavily on steel and wood materials, which require significant energy for production and generate substantial waste during dismantling, negatively impacting the environment. Exoskeleton scaffolds utilize modular, reusable components that reduce material consumption and minimize waste, promoting sustainable construction practices. This shift towards sustainable scaffolding systems contributes to lower carbon footprints and supports green building certifications.

Future Trends in Construction Scaffolding

Future trends in construction scaffolding emphasize increased safety, efficiency, and adaptability with the growing adoption of exoskeleton scaffolds over traditional scaffolding methods. Exoskeleton scaffolds integrate advanced materials like lightweight alloys and smart sensors, enhancing worker mobility and real-time monitoring capabilities. These innovations drive reduced setup times, lower labor costs, and improved compliance with evolving safety regulations in the construction industry.

Related Important Terms

Tube-and-Coupler Scaffolding

Tube-and-coupler scaffolding, a key type of traditional scaffolding, consists of steel tubes and couplers offering high versatility and adaptability for complex structures in construction projects. Compared to exoskeleton scaffolds, tube-and-coupler systems provide customizable configurations and robust load-bearing capabilities but often require more labor-intensive assembly and dismantling processes.

Modular Scaffolding Systems

Modular scaffolding systems in both traditional scaffolding and exoskeleton scaffolding offer customizable configurations that enhance on-site flexibility and safety. Exoskeleton scaffolds provide superior load distribution and reduced assembly time compared to traditional modular scaffolding, making them ideal for complex construction projects requiring rapid deployment and high structural integrity.

Frame Scaffold

Frame scaffold, a traditional scaffolding system, provides a versatile and cost-effective solution for construction projects with its simple assembly and widespread availability, ideal for moderate heights and straightforward tasks. Exoskeleton scaffolding offers enhanced safety and stability through integrated harness systems and load-bearing frames, making it suitable for complex structures and heavy-duty applications where worker protection and mobility are critical.

Exoskeleton Scaffold Structure

Exoskeleton scaffold structures provide enhanced stability and load-bearing capacity by integrating a rigid frame system directly onto the exterior of buildings, optimizing safety in high-rise construction. These scaffolds facilitate faster assembly and disassembly compared to traditional scaffolding, reducing labor costs and improving project timelines.

Robotics-Assisted Exoskeletons

Robotics-assisted exoskeleton scaffolds enhance construction safety and efficiency by providing workers with augmented strength and reduced fatigue during heavy lifting and repetitive tasks. Unlike traditional scaffolding, these advanced frameworks integrate wearable robotic systems that improve mobility and minimize ergonomic risks on construction sites.

Prefabricated Scaffold Elements

Prefabricated scaffold elements in traditional scaffolding typically include standardized steel or aluminum components such as frames, braces, and planks, allowing for modular assembly on-site with proven durability and flexibility. Exoskeleton scaffolds utilize prefabricated, lightweight composite materials designed for rapid installation and enhanced worker ergonomics, improving safety and efficiency in complex construction environments.

Adaptive Load Distribution

Traditional scaffolding relies on fixed support points that can create uneven load distribution, increasing stress on specific areas and potentially compromising safety. Exoskeleton scaffolds feature adaptive load distribution systems that dynamically balance weight across the structure, enhancing stability and reducing material fatigue during construction projects.

Digital Scaffold Modeling (BIM Integration)

Traditional scaffolding relies on manual design and assembly with limited digital integration, whereas exoskeleton scaffolds leverage advanced Digital Scaffold Modeling through BIM integration for enhanced precision, real-time adjustments, and improved safety management. BIM-enabled exoskeleton scaffolding streamlines project coordination, facilitates clash detection, and optimizes material usage, reducing costs and construction timelines significantly.

Human-Assist Exosuit Scaffolds

Human-assist exosuit scaffolds integrate wearable robotic systems that enhance worker strength and reduce fatigue while providing stable support at height, offering significant ergonomic and safety advantages over traditional scaffolding methods. These exoskeleton scaffold systems improve construction efficiency by enabling greater mobility and load-bearing capacity, minimizing the risk of musculoskeletal injuries commonly associated with manual scaffold use.

Smart Scaffold Monitoring Sensors

Smart scaffold monitoring sensors integrated into exoskeleton scaffolds provide real-time data on structural integrity, load distribution, and environmental conditions, significantly enhancing worker safety and reducing the risk of accidents compared to traditional scaffolding methods. These advanced sensors enable proactive maintenance and immediate alerts, optimizing construction site efficiency and compliance with safety regulations.

Traditional Scaffolding vs Exoskeleton Scaffold Infographic

industrydif.com

industrydif.com