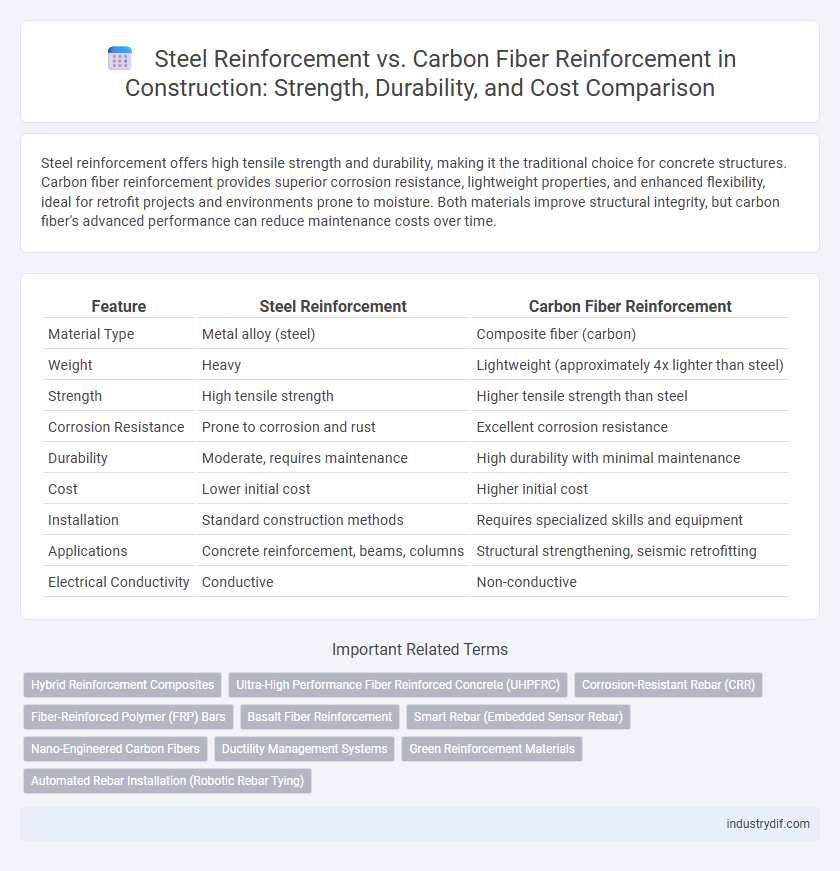

Steel reinforcement offers high tensile strength and durability, making it the traditional choice for concrete structures. Carbon fiber reinforcement provides superior corrosion resistance, lightweight properties, and enhanced flexibility, ideal for retrofit projects and environments prone to moisture. Both materials improve structural integrity, but carbon fiber's advanced performance can reduce maintenance costs over time.

Table of Comparison

| Feature | Steel Reinforcement | Carbon Fiber Reinforcement |

|---|---|---|

| Material Type | Metal alloy (steel) | Composite fiber (carbon) |

| Weight | Heavy | Lightweight (approximately 4x lighter than steel) |

| Strength | High tensile strength | Higher tensile strength than steel |

| Corrosion Resistance | Prone to corrosion and rust | Excellent corrosion resistance |

| Durability | Moderate, requires maintenance | High durability with minimal maintenance |

| Cost | Lower initial cost | Higher initial cost |

| Installation | Standard construction methods | Requires specialized skills and equipment |

| Applications | Concrete reinforcement, beams, columns | Structural strengthening, seismic retrofitting |

| Electrical Conductivity | Conductive | Non-conductive |

Introduction to Reinforcement Materials in Construction

Steel reinforcement remains the most widely used material in construction due to its high tensile strength, durability, and cost-effectiveness for concrete structures. Carbon fiber reinforcement offers superior corrosion resistance and a higher strength-to-weight ratio, making it ideal for applications requiring lightweight and long-lasting solutions. Understanding the distinct mechanical properties and environmental advantages of both materials is crucial for optimizing structural performance and longevity.

Understanding Steel Reinforcement: Properties and Applications

Steel reinforcement offers high tensile strength and excellent ductility, making it ideal for load-bearing concrete structures such as beams, columns, and slabs. Its corrosion resistance can be enhanced through coatings or galvanization, ensuring durability in various environmental conditions. Commonly used due to its cost-effectiveness and compatibility with concrete, steel reinforcement remains a preferred choice in infrastructure projects like bridges, buildings, and highways.

Carbon Fiber Reinforcement: Composition and Key Features

Carbon fiber reinforcement consists primarily of high-strength carbon filaments bonded with a polymer resin matrix, offering exceptional tensile strength and lightweight characteristics compared to traditional steel reinforcement. Its corrosion resistance and flexibility enable enhanced durability and adaptability in seismic zones and harsh environments. This composite material significantly reduces structural weight while maintaining superior load-bearing capacity, making it ideal for retrofitting and advanced construction applications.

Strength and Durability Comparison: Steel vs Carbon Fiber

Steel reinforcement provides high tensile strength and excellent load-bearing capacity, making it suitable for heavy construction projects. Carbon fiber reinforcement offers superior corrosion resistance and fatigue durability, significantly extending the lifespan of structures in harsh environments. Despite carbon fiber's higher initial cost, its combination of lightweight properties and long-term performance makes it a durable alternative to traditional steel reinforcement in modern construction.

Weight and Structural Efficiency Differences

Steel reinforcement offers high tensile strength but is significantly heavier than carbon fiber reinforcement, impacting overall structural weight and increasing load on foundations. Carbon fiber reinforcement provides superior strength-to-weight ratio, enabling lighter and more efficient structural designs without compromising durability. This weight advantage enhances seismic performance and reduces transportation and installation costs in construction projects.

Corrosion Resistance: Longevity in Challenging Environments

Steel reinforcement offers robust structural support but is prone to corrosion, especially in moist or saline environments, which can compromise longevity and increase maintenance costs. Carbon fiber reinforcement exhibits superior corrosion resistance, maintaining strength and durability in harsh conditions such as marine or chemically aggressive settings. This corrosion resistance translates to enhanced longevity and reduced lifecycle expenses, making carbon fiber an optimal choice for infrastructure exposed to challenging environmental factors.

Installation Process and Workability Considerations

Steel reinforcement requires heavy machinery for cutting, bending, and tying, which lengthens installation time and demands skilled labor. Carbon fiber reinforcement offers superior flexibility and lightweight handling, allowing faster application with adhesive bonding or wrapping techniques on complex surfaces. Workability favors carbon fiber due to corrosion resistance and reduced need for protective coatings, significantly decreasing maintenance efforts compared to steel.

Cost Implications: Initial Investment and Lifecycle Analysis

Steel reinforcement typically features lower initial costs compared to carbon fiber reinforcement, making it a preferred choice for budget-sensitive construction projects. Carbon fiber reinforcement, despite its higher upfront investment, offers superior durability and corrosion resistance, which can reduce long-term maintenance and replacement expenses. Lifecycle cost analysis reveals that carbon fiber's extended service life and minimal upkeep may offset its initial premium, resulting in potentially greater cost efficiency over the infrastructure's lifespan.

Industry Applications: Optimal Uses for Each Material

Steel reinforcement remains the preferred choice for high-load structural elements in commercial and residential buildings due to its exceptional tensile strength and cost-effectiveness. Carbon fiber reinforcement excels in applications demanding lightweight and corrosion-resistant materials, such as bridge retrofitting, seismic strengthening, and specialized infrastructure projects. Combining steel and carbon fiber reinforcement can optimize performance by leveraging steel's ductility and carbon fiber's durability in complex construction environments.

Future Trends and Innovations in Construction Reinforcement

Future trends in construction reinforcement are shifting towards carbon fiber composites due to their superior strength-to-weight ratio, corrosion resistance, and ease of installation compared to traditional steel reinforcement. Innovations include the development of hybrid reinforcement systems that combine steel and carbon fiber to optimize structural performance and durability while reducing maintenance costs. Advances in nanotechnology and smart monitoring systems integrated with carbon fiber reinforcement are enhancing real-time structural health monitoring and predictive maintenance capabilities in modern construction projects.

Related Important Terms

Hybrid Reinforcement Composites

Hybrid reinforcement composites combine steel reinforcement and carbon fiber reinforcement to enhance structural performance by leveraging steel's tensile strength and carbon fiber's corrosion resistance and high stiffness. This hybrid approach optimizes load-bearing capacity, durability, and longevity in concrete structures, reducing maintenance costs and improving seismic resilience.

Ultra-High Performance Fiber Reinforced Concrete (UHPFRC)

Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) enhanced with carbon fiber reinforcement offers superior tensile strength, corrosion resistance, and durability compared to traditional steel reinforcement, making it ideal for advanced structural applications. Carbon fiber reinforcement in UHPFRC reduces weight while improving flexural performance and crack control, significantly extending the lifespan of infrastructure exposed to aggressive environments.

Corrosion-Resistant Rebar (CRR)

Corrosion-resistant rebar (CRR) offers superior durability compared to traditional steel reinforcement by significantly reducing the risk of rust and structural degradation in concrete applications, especially in harsh environments. Carbon fiber reinforcement provides high tensile strength and lightweight advantages but lacks the long-term corrosion resistance and cost-effectiveness demonstrated by CRR in infrastructure projects.

Fiber-Reinforced Polymer (FRP) Bars

Fiber-Reinforced Polymer (FRP) bars, particularly carbon fiber variants, offer superior corrosion resistance and high tensile strength compared to conventional steel reinforcement, making them ideal for structures exposed to aggressive environments. Their lightweight nature reduces handling and installation costs while extending the lifespan of concrete elements by preventing rust-induced deterioration common in steel-reinforced constructions.

Basalt Fiber Reinforcement

Basalt fiber reinforcement offers superior corrosion resistance and higher tensile strength compared to traditional steel and carbon fiber reinforcements, making it an ideal choice for enhancing the durability and longevity of concrete structures. Its lightweight nature reduces structural load while providing excellent thermal stability and cost-effectiveness in large-scale construction projects.

Smart Rebar (Embedded Sensor Rebar)

Smart rebar, embedded with advanced sensors, enhances structural health monitoring by providing real-time data on stress, strain, and corrosion in both steel and carbon fiber reinforcement systems. This technology enables proactive maintenance and extends the lifespan of reinforced concrete structures by detecting potential failures before they become critical.

Nano-Engineered Carbon Fibers

Nano-engineered carbon fibers exhibit superior tensile strength and corrosion resistance compared to traditional steel reinforcement, significantly enhancing the durability and lifespan of concrete structures. Their lightweight properties also reduce structural load, enabling innovative design flexibility and improved seismic performance in construction projects.

Ductility Management Systems

Steel reinforcement offers superior ductility essential for energy dissipation in seismic design, making it a reliable choice for ductility management systems in construction. Carbon fiber reinforcement provides high tensile strength with lightweight properties but typically lacks the inherent ductility steel offers, necessitating hybrid systems or additional design considerations to achieve effective ductility management.

Green Reinforcement Materials

Steel reinforcement offers high tensile strength and durability but has a significant carbon footprint due to energy-intensive production processes. Carbon fiber reinforcement provides a lightweight, corrosion-resistant alternative with lower embodied carbon, making it a more sustainable choice for green construction projects.

Automated Rebar Installation (Robotic Rebar Tying)

Automated rebar installation using robotic rebar tying enhances the efficiency and precision of steel reinforcement placement by reducing labor costs and minimizing human error. In contrast, carbon fiber reinforcement, while offering superior corrosion resistance and lightweight properties, requires specialized handling that currently limits automation scalability compared to traditional steel rebar systems.

Steel Reinforcement vs Carbon Fiber Reinforcement Infographic

industrydif.com

industrydif.com