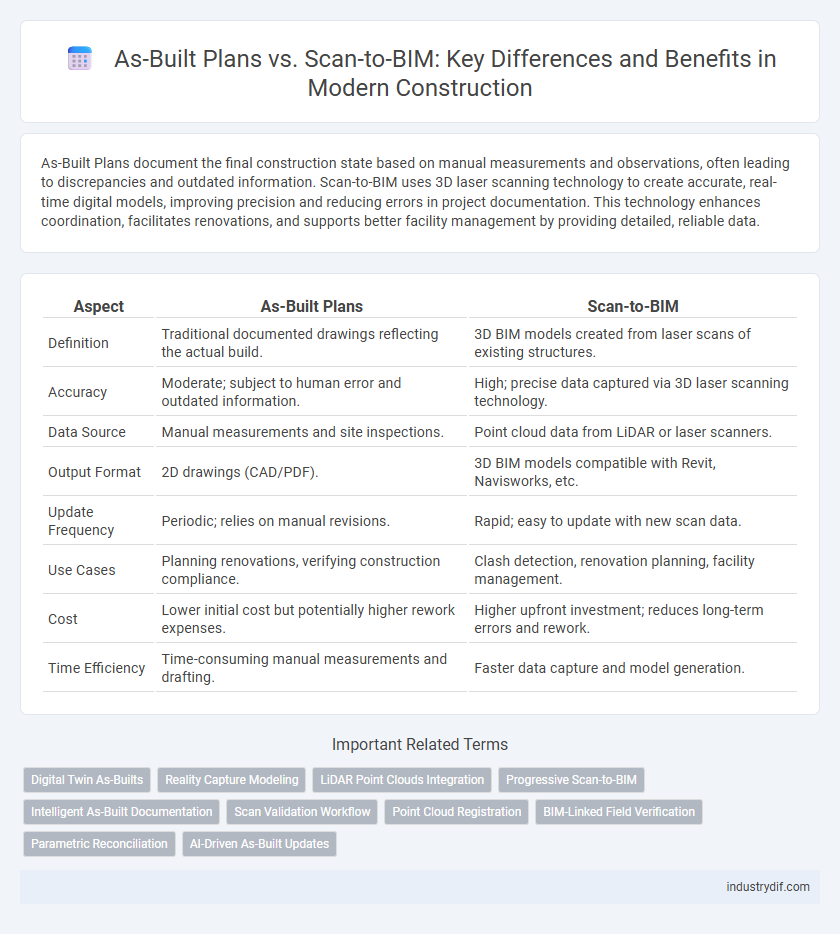

As-Built Plans document the final construction state based on manual measurements and observations, often leading to discrepancies and outdated information. Scan-to-BIM uses 3D laser scanning technology to create accurate, real-time digital models, improving precision and reducing errors in project documentation. This technology enhances coordination, facilitates renovations, and supports better facility management by providing detailed, reliable data.

Table of Comparison

| Aspect | As-Built Plans | Scan-to-BIM |

|---|---|---|

| Definition | Traditional documented drawings reflecting the actual build. | 3D BIM models created from laser scans of existing structures. |

| Accuracy | Moderate; subject to human error and outdated information. | High; precise data captured via 3D laser scanning technology. |

| Data Source | Manual measurements and site inspections. | Point cloud data from LiDAR or laser scanners. |

| Output Format | 2D drawings (CAD/PDF). | 3D BIM models compatible with Revit, Navisworks, etc. |

| Update Frequency | Periodic; relies on manual revisions. | Rapid; easy to update with new scan data. |

| Use Cases | Planning renovations, verifying construction compliance. | Clash detection, renovation planning, facility management. |

| Cost | Lower initial cost but potentially higher rework expenses. | Higher upfront investment; reduces long-term errors and rework. |

| Time Efficiency | Time-consuming manual measurements and drafting. | Faster data capture and model generation. |

Understanding As-Built Plans in Construction

As-built plans document the exact dimensions and conditions of a construction project after completion, reflecting all changes made during the build process. These plans are essential for facility management, renovations, and ensuring compliance with design specifications. Understanding as-built plans enables accurate record-keeping and reduces costly errors in future construction phases.

What is Scan-to-BIM?

Scan-to-BIM is a cutting-edge construction process that converts laser scan data into accurate 3D Building Information Models, enabling precise documentation of existing structures. Unlike traditional As-Built Plans, which rely on manual measurements and 2D drawings, Scan-to-BIM captures detailed geometric and spatial data with high-resolution point clouds. This technology enhances project accuracy, facilitates clash detection, and streamlines renovation, retrofit, and facility management workflows.

Key Differences: As-Built Plans vs Scan-to-BIM

As-Built Plans are traditionally hand-drawn or CAD-drafted documents created post-construction to reflect the final built conditions, often containing inaccuracies due to manual measurements. Scan-to-BIM utilizes laser scanning and photogrammetry to generate highly accurate 3D models that capture precise dimensions and spatial relationships in real-time. The key difference lies in Scan-to-BIM's integration of point cloud data, offering superior detail and reducing errors compared to conventional As-Built Plans, enhancing project coordination and facility management.

Accuracy and Detail Level Comparison

As-built plans provide a traditional record of completed construction projects, offering basic dimensions and modifications but often lack the precision found in modern methods. Scan-to-BIM leverages 3D laser scanning technology to create highly accurate, detailed digital models, capturing complex geometry and small-scale features that as-built plans may overlook. The enhanced accuracy and comprehensive detail level of Scan-to-BIM significantly improve project documentation, clash detection, and future renovations efficiency.

Technology Used in Scan-to-BIM

Scan-to-BIM technology utilizes advanced 3D laser scanning and photogrammetry to capture precise as-built conditions, enabling accurate digital models for renovation or construction projects. This method integrates LiDAR, point cloud data processing software, and BIM platforms such as Autodesk Revit to streamline design modifications and reduce human errors. Compared to traditional as-built plans, Scan-to-BIM improves data accuracy and project visualization through real-time updates and collaboration tools.

Traditional Methods Behind As-Built Plans

Traditional as-built plans rely heavily on manual measurements and field sketches, often resulting in inaccuracies and outdated documentation. These methods depend on physical site visits and manual data entry, which can lead to errors and extended project timelines. Compared to Scan-to-BIM technology, traditional as-built plans lack the precision and efficiency provided by 3D laser scans and digital modeling.

Benefits of Scan-to-BIM for Construction Projects

Scan-to-BIM technology offers precise 3D models that enhance accuracy in construction project planning and execution, reducing costly errors and rework. It captures real-time as-built conditions, enabling seamless integration with existing designs and improving collaboration between stakeholders. This method accelerates project timelines and optimizes resource allocation by providing detailed, data-rich models that support informed decision-making throughout the construction lifecycle.

Challenges in Creating As-Built Plans

Creating As-Built Plans presents challenges such as inaccuracies from manual measurements and incomplete documentation during construction, leading to discrepancies between design and the actual structure. Traditional methods are time-consuming and prone to human error, complicating project timelines and cost estimations. Integrating Scan-to-BIM technology addresses these issues by enabling precise 3D modeling through laser scans, yet it requires significant expertise and investment in advanced software and hardware.

When to Choose Scan-to-BIM Over As-Built Plans

Scan-to-BIM is ideal when dealing with complex or irregular structures where precision is critical, capturing exact site conditions with 3D laser scanning technology. It significantly reduces errors and rework by providing highly accurate, up-to-date digital models compared to traditional As-Built Plans that may lack detail or become outdated. Projects requiring detailed renovation, retrofitting, or integration of new systems benefit most from the precise spatial data in Scan-to-BIM workflows.

Future Trends: Digitalization in Construction Documentation

Future trends in construction documentation emphasize digitalization, with Scan-to-BIM replacing traditional As-Built Plans by providing highly accurate, real-time 3D models that enhance project visualization and coordination. Scan-to-BIM integrates laser scanning and Building Information Modeling to capture precise as-built conditions, streamlining updates and reducing errors compared to conventional 2D drawings. This shift supports efficient facility management, improved asset lifecycle tracking, and seamless collaboration across construction stakeholders through cloud-based platforms.

Related Important Terms

Digital Twin As-Builts

Digital Twin As-Built plans enhance traditional As-Built documentation by integrating real-time 3D Scan-to-BIM data, offering precise, up-to-date digital replicas of physical structures. This technology improves facility management, reduces errors in renovation projects, and supports predictive maintenance by providing comprehensive, data-rich models beyond standard 2D drawings.

Reality Capture Modeling

As-Built Plans document the final construction status based on traditional measurements, often lacking real-time accuracy and detailed spatial data, whereas Scan-to-BIM leverages reality capture modeling through 3D laser scanning and photogrammetry to create precise, data-rich digital twins of physical structures. Reality capture modeling enhances project coordination, reduces rework, and improves facility management by integrating as-built conditions directly into BIM workflows.

LiDAR Point Clouds Integration

As-built plans provide detailed documentation of completed construction projects, but integration of LiDAR point clouds in scan-to-BIM enhances accuracy by capturing real-world conditions in high-resolution 3D models. Leveraging LiDAR data enables precise alignment and comprehensive verification of structural elements, streamlining renovation and facility management workflows.

Progressive Scan-to-BIM

Progressive Scan-to-BIM integrates continuous laser scanning data into updated 3D models, enhancing accuracy and reducing errors compared to traditional As-Built Plans that rely on manual measurements. This method improves project documentation by capturing real-time changes during construction, facilitating better collaboration and decision-making throughout the building lifecycle.

Intelligent As-Built Documentation

Intelligent As-Built Documentation integrates Scan-to-BIM technology to create highly accurate, data-rich 3D models that surpass traditional As-Built Plans by capturing precise geometries and real-time conditions. This process enhances construction project management, facility maintenance, and renovation workflows by providing comprehensive, easily updatable digital records.

Scan Validation Workflow

Scan validation workflow in Scan-to-BIM integrates laser scanning data with Building Information Modeling to ensure accurate as-built conditions by detecting deviations and updating models in real-time. This process enhances construction accuracy, reduces costly rework, and improves project delivery by verifying structural compliance through precise point cloud comparisons.

Point Cloud Registration

Point Cloud Registration in Scan-to-BIM enhances accuracy by aligning laser-scanned data with digital models, enabling precise as-built conditions capture compared to traditional As-Built Plans, which rely on manual measurements prone to errors. This advanced registration process streamlines construction documentation, improves clash detection, and facilitates efficient project management through detailed 3D spatial information.

BIM-Linked Field Verification

BIM-linked field verification integrates real-time scan data with Building Information Modeling, enabling precise updates to as-built plans that reflect exact onsite conditions. This digital methodology enhances accuracy and streamlines collaboration by bridging the gap between physical construction progress and virtual models.

Parametric Reconciliation

Parametric reconciliation in construction bridges the gap between traditional As-Built Plans and advanced Scan-to-BIM workflows by integrating precise 3D laser scan data with parametric building information models. This enables real-time updates and accurate representation of design changes, enhancing project accuracy and facilitating clash detection during complex renovations.

AI-Driven As-Built Updates

AI-driven as-built updates leverage advanced machine learning algorithms and 3D scanning technology to generate precise, real-time models that improve accuracy over traditional as-built plans. This Scan-to-BIM process enhances construction project management by automating data integration, reducing manual errors, and enabling seamless collaboration across stakeholders.

As-Built Plans vs Scan-to-BIM Infographic

industrydif.com

industrydif.com