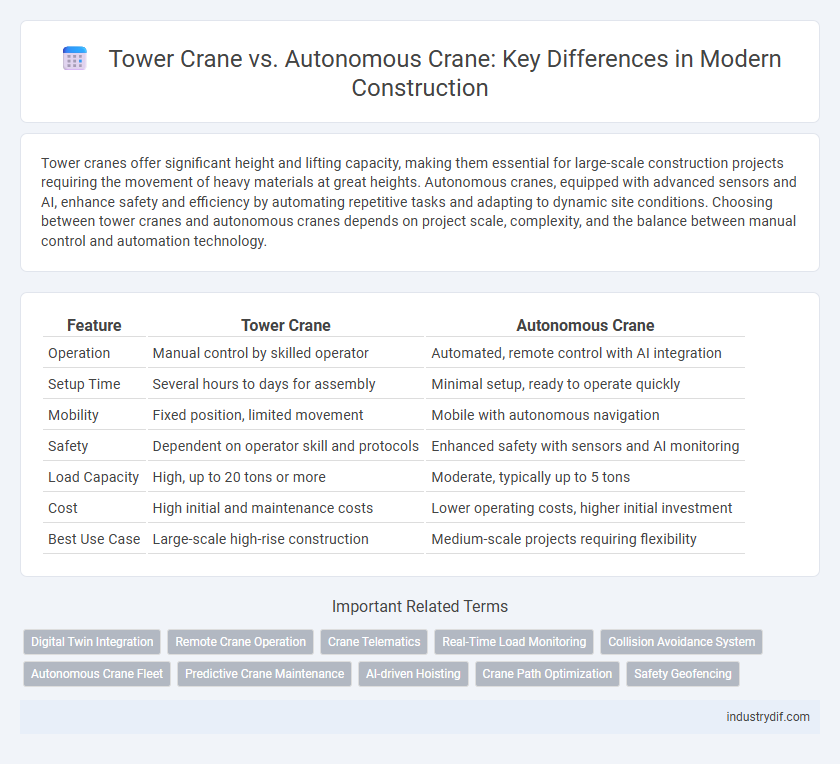

Tower cranes offer significant height and lifting capacity, making them essential for large-scale construction projects requiring the movement of heavy materials at great heights. Autonomous cranes, equipped with advanced sensors and AI, enhance safety and efficiency by automating repetitive tasks and adapting to dynamic site conditions. Choosing between tower cranes and autonomous cranes depends on project scale, complexity, and the balance between manual control and automation technology.

Table of Comparison

| Feature | Tower Crane | Autonomous Crane |

|---|---|---|

| Operation | Manual control by skilled operator | Automated, remote control with AI integration |

| Setup Time | Several hours to days for assembly | Minimal setup, ready to operate quickly |

| Mobility | Fixed position, limited movement | Mobile with autonomous navigation |

| Safety | Dependent on operator skill and protocols | Enhanced safety with sensors and AI monitoring |

| Load Capacity | High, up to 20 tons or more | Moderate, typically up to 5 tons |

| Cost | High initial and maintenance costs | Lower operating costs, higher initial investment |

| Best Use Case | Large-scale high-rise construction | Medium-scale projects requiring flexibility |

Introduction to Tower Cranes and Autonomous Cranes

Tower cranes are essential vertical lifting machines commonly used in construction sites for hoisting heavy materials to great heights, featuring a fixed or mobile base with a tall mast and a horizontal jib. Autonomous cranes leverage advanced sensor technologies and AI-driven control systems to perform lifting operations without direct human intervention, enhancing safety and efficiency in complex construction environments. Both tower cranes and autonomous cranes contribute to modern construction by optimizing material handling, though autonomous cranes offer increased precision and reduced labor dependence.

Evolution of Crane Technology in Construction

Tower cranes have evolved significantly, integrating advanced sensors and automation to enhance precision and safety in high-rise construction. Autonomous cranes leverage AI-powered systems and real-time data analytics to optimize load handling and reduce human error on busy sites. This technological progression marks a shift from manual operation to intelligent, adaptive machinery that improves efficiency and project timelines.

Key Features of Traditional Tower Cranes

Traditional tower cranes offer high load capacity and extensive reach, enabling the lifting of heavy materials to great heights on construction sites. Their fixed mast design ensures stability and precision during complex lifting operations, supported by a counterweight system that balances heavy loads. Manual operation with experienced crane operators allows for adaptable control but often requires significant onsite coordination and safety measures.

Core Advantages of Autonomous Cranes

Autonomous cranes offer enhanced precision and safety by using advanced sensors and AI-driven controls to minimize human error and optimize load handling on construction sites. These cranes operate continuously with minimal downtime, increasing productivity and reducing labor costs compared to traditional tower cranes. Their ability to perform complex maneuvers autonomously improves site efficiency and project timelines, especially in hazardous or confined environments.

Safety Considerations: Tower Crane vs Autonomous Crane

Tower cranes require constant human operation, increasing the risk of human error-related accidents, whereas autonomous cranes utilize advanced sensors and AI to enhance precision and minimize hazardous situations. The integration of real-time monitoring systems in autonomous cranes allows for immediate detection and mitigation of safety risks, surpassing traditional tower crane protocols. Maintenance routines for autonomous cranes rely on predictive analytics, reducing unexpected failures and contributing to a safer construction environment compared to manual inspections of tower cranes.

Efficiency and Productivity Comparisons

Tower cranes offer high lifting capacity and reach, making them ideal for large-scale construction projects requiring heavy material handling. Autonomous cranes enhance efficiency by utilizing advanced sensors and AI for precision operation, reducing human error and downtime. Comparing productivity, autonomous cranes can operate continuously with minimal supervision, improving project timelines, whereas tower cranes depend heavily on skilled operators for optimal performance.

Cost Implications and ROI Analysis

Tower cranes require significant upfront investment and ongoing operational costs, including assembly, disassembly, and skilled labor, impacting overall project budgets. Autonomous cranes, while having higher initial technology integration expenses, offer reduced labor costs and enhanced operational efficiency, potentially accelerating return on investment through minimized downtime and improved precision. Evaluating total cost of ownership and project duration reveals that autonomous cranes can deliver superior ROI in large-scale, repetitive construction tasks compared to traditional tower cranes.

Integration with Smart Construction Sites

Tower cranes enhance smart construction sites through precise load management and real-time data connectivity, enabling advanced project monitoring and safety compliance. Autonomous cranes integrate with IoT sensors and AI algorithms for automated operation, improving efficiency and reducing human error in complex tasks. Both technologies contribute to seamless interoperability within digital construction ecosystems, optimizing workflow and resource allocation on modern sites.

Environmental Impact and Sustainability

Tower cranes contribute to construction efficiency but have significant environmental footprints due to heavy fuel consumption and CO2 emissions from diesel engines. Autonomous cranes, equipped with electric propulsion and smart energy management systems, reduce greenhouse gas emissions and noise pollution, promoting sustainable construction practices. Integrating autonomous cranes supports eco-friendly site operations by minimizing carbon output and optimizing energy use.

Future Trends: The Shift Toward Autonomy in Lifting Equipment

Tower cranes remain essential for high-rise construction projects, but the future of lifting equipment is rapidly shifting toward autonomous cranes equipped with AI and advanced sensors. These autonomous cranes enhance site safety, optimize load management, and reduce human error, driving efficiency in complex construction environments. Integration with Building Information Modeling (BIM) and IoT technologies positions autonomous cranes as a cornerstone in the evolution of smart construction sites.

Related Important Terms

Digital Twin Integration

Tower cranes equipped with digital twin integration enable real-time monitoring and predictive maintenance, significantly enhancing operational efficiency and safety on construction sites. Autonomous cranes leverage digital twin technology for precise movement coordination and adaptive task management, reducing human error and optimizing construction workflows.

Remote Crane Operation

Remote crane operation enhances safety and efficiency by allowing tower cranes to be controlled from a distance, minimizing on-site personnel exposure to hazardous conditions. Autonomous cranes integrate AI-driven systems for precision and continuous operation, reducing human error and improving productivity in complex construction environments.

Crane Telematics

Tower cranes equipped with advanced telematics systems provide real-time data on load weight, wind speed, and crane positioning, enhancing safety and operational efficiency on construction sites. Autonomous cranes integrate telematics with AI-driven control, enabling precision in lift planning and remote monitoring, which reduces human error and improves overall project productivity.

Real-Time Load Monitoring

Tower cranes utilize advanced load cells and sensors integrated with real-time monitoring systems to ensure precise load weight measurements and enhance operational safety. Autonomous cranes employ AI-driven analytics combined with continuous load data feedback for adaptive control, minimizing risks and optimizing load handling efficiency on construction sites.

Collision Avoidance System

Tower cranes utilize basic collision avoidance systems relying on manual controls and limited sensors, whereas autonomous cranes integrate advanced LiDAR, radar, and AI-powered algorithms to detect obstacles in real time, enabling proactive collision prevention. These sophisticated systems in autonomous cranes significantly enhance safety and operational efficiency by minimizing human error and optimizing crane movement within complex construction environments.

Autonomous Crane Fleet

Autonomous crane fleets revolutionize construction by enhancing efficiency through AI-driven coordination, real-time data analytics, and remote operation, reducing human error and downtime on-site. These fleets integrate advanced sensors and machine learning algorithms to optimize load handling, improve safety, and accelerate project timelines compared to traditional tower cranes.

Predictive Crane Maintenance

Predictive crane maintenance leverages IoT sensors and AI algorithms to monitor tower crane components in real-time, reducing unexpected downtime and enhancing safety by forecasting wear and mechanical failures. Autonomous cranes integrate advanced diagnostics and machine learning for continuous performance assessment, enabling more precise and timely maintenance schedules compared to traditional tower cranes.

AI-driven Hoisting

AI-driven hoisting in autonomous cranes enhances precision and safety by leveraging real-time data analytics and machine learning algorithms, reducing human error compared to traditional tower cranes. Autonomous cranes optimize load management and operational efficiency through advanced sensors and AI, surpassing conventional crane performance in complex construction environments.

Crane Path Optimization

Tower cranes benefit from fixed, pre-planned paths optimized for repetitive lifting tasks on construction sites, ensuring consistent load management and minimal collision risk. Autonomous cranes utilize real-time sensor data and AI algorithms to dynamically optimize their paths, enhancing flexibility and efficiency in complex or changing site conditions.

Safety Geofencing

Tower cranes equipped with advanced safety geofencing use GPS and sensors to create virtual boundaries that prevent hazardous operations near restricted zones, significantly reducing collision risks on construction sites. Autonomous cranes integrate AI-driven geofencing for real-time hazard detection and adaptive operational limits, enhancing worker safety and compliance with site regulations.

Tower Crane vs Autonomous Crane Infographic

industrydif.com

industrydif.com