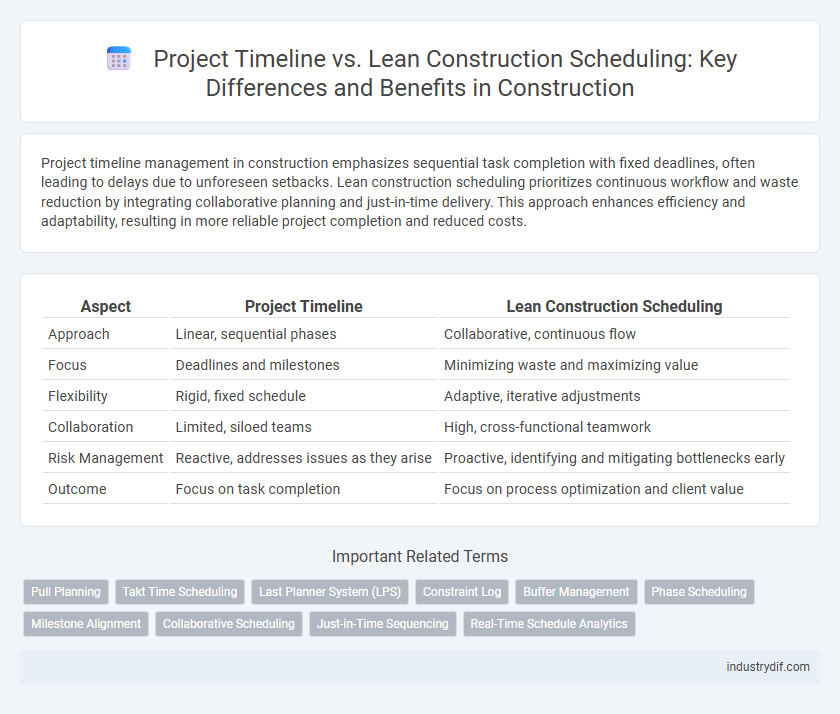

Project timeline management in construction emphasizes sequential task completion with fixed deadlines, often leading to delays due to unforeseen setbacks. Lean construction scheduling prioritizes continuous workflow and waste reduction by integrating collaborative planning and just-in-time delivery. This approach enhances efficiency and adaptability, resulting in more reliable project completion and reduced costs.

Table of Comparison

| Aspect | Project Timeline | Lean Construction Scheduling |

|---|---|---|

| Approach | Linear, sequential phases | Collaborative, continuous flow |

| Focus | Deadlines and milestones | Minimizing waste and maximizing value |

| Flexibility | Rigid, fixed schedule | Adaptive, iterative adjustments |

| Collaboration | Limited, siloed teams | High, cross-functional teamwork |

| Risk Management | Reactive, addresses issues as they arise | Proactive, identifying and mitigating bottlenecks early |

| Outcome | Focus on task completion | Focus on process optimization and client value |

Understanding Traditional Project Timelines in Construction

Traditional project timelines in construction typically follow a linear, sequential approach with defined phases such as design, procurement, and construction, often leading to rigid schedules and limited flexibility. These timelines are prone to delays due to inefficiencies, resource bottlenecks, and misaligned task dependencies. Understanding this baseline highlights the advantages of lean construction scheduling, which emphasizes continuous workflow, collaboration, and waste reduction to optimize project delivery.

The Fundamentals of Lean Construction Scheduling

Lean construction scheduling emphasizes maximizing value by minimizing waste and improving workflow efficiency through detailed task sequencing and continuous feedback loops. It prioritizes collaborative planning, real-time adjustments, and pull-based scheduling techniques to ensure timely project completion and resource optimization. This approach contrasts traditional project timelines by focusing on iterative progress and flexibility rather than fixed, linear schedules.

Key Differences Between Project Timelines and Lean Scheduling

Project timelines traditionally follow a sequential, fixed-date approach prioritizing milestones and deadlines, whereas Lean construction scheduling emphasizes continuous workflow improvements and waste reduction through just-in-time task sequencing. Lean scheduling integrates real-time data and collaborative planning to adapt project activities dynamically, enhancing efficiency and resource utilization compared to static project timelines. The key difference lies in Lean's focus on flexibility and value stream optimization, contrasting with the rigid, date-driven nature of conventional project timelines.

Benefits of Lean Scheduling Over Traditional Timelines

Lean construction scheduling enhances project efficiency by minimizing waste and optimizing resource allocation, resulting in shorter project timelines compared to traditional methods. It promotes continuous flow and just-in-time delivery, which reduces delays and accelerates task completion. This approach improves team collaboration and adaptability, leading to higher quality outcomes and lower overall project costs.

Common Pitfalls in Conventional Construction Scheduling

Conventional construction scheduling often suffers from rigid project timelines that fail to accommodate real-time changes, leading to delays and cost overruns. Common pitfalls include inaccurate time estimates, lack of collaboration among stakeholders, and insufficient flexibility to address unforeseen site conditions. Lean construction scheduling mitigates these issues by emphasizing continuous improvement, just-in-time delivery, and integrated planning processes that enhance efficiency and reduce waste.

Lean Principles Applied to Construction Project Management

Lean construction scheduling reduces waste and enhances efficiency by integrating continuous workflow optimization and real-time collaboration across teams. Applying lean principles like just-in-time delivery, pull planning, and value stream mapping accelerates project timelines while maintaining high-quality standards. This approach minimizes delays and cost overruns by fostering transparency, early problem identification, and adaptive resource allocation throughout the construction process.

Tools and Techniques for Lean Construction Scheduling

Lean construction scheduling utilizes tools like Last Planner System, pull planning, and target value design to optimize project timelines by minimizing waste and enhancing workflow reliability. Techniques such as visual scheduling boards, constraint analysis, and continuous improvement cycles enable teams to manage tasks collaboratively and adjust dynamically to project changes. These methods improve timeline adherence by promoting transparency, accountability, and just-in-time task execution in construction projects.

Impact of Lean Scheduling on Project Delivery and Costs

Lean Construction scheduling significantly enhances project delivery by reducing waste, improving workflow efficiency, and minimizing delays, resulting in shorter project timelines compared to traditional scheduling methods. The streamlined processes enable real-time adjustments and better resource allocation, which directly lower overall project costs by reducing labor, material overruns, and idle time. Data from industry case studies show projects implementing Lean scheduling achieve up to 25% faster completion and cost savings of 10-15%, emphasizing its critical role in optimizing construction performance.

Integrating Lean Scheduling with Existing Project Timelines

Integrating lean construction scheduling with existing project timelines enhances workflow efficiency by emphasizing value-driven activities and minimizing waste. Lean scheduling tools, such as the Last Planner System, provide real-time, collaborative updates that align with traditional Gantt charts, enabling adaptive adjustments without disrupting overall deadlines. This synergy improves project predictability, reduces delays, and fosters continuous improvement across all construction phases.

Case Studies: Success Stories of Lean Construction Scheduling

Case studies demonstrate that Lean Construction Scheduling significantly reduces project timelines by eliminating waste and improving workflow efficiency on construction sites. Projects implementing Lean principles report up to 30% faster completion rates compared to traditional scheduling methods, with enhanced collaboration and resource optimization driving these improvements. Success stories from sectors such as commercial buildings and infrastructure highlight how Lean methodologies lead to cost savings and increased stakeholder satisfaction.

Related Important Terms

Pull Planning

Project timeline management in construction benefits significantly from Lean Construction Scheduling, particularly through Pull Planning, which emphasizes collaborative task sequencing to optimize workflow and minimize delays. Pull Planning aligns tasks with project milestones by involving all stakeholders in reverse scheduling, enhancing efficiency and ensuring timely project completion.

Takt Time Scheduling

Takt Time Scheduling in Lean Construction optimizes project timelines by aligning workflow with customer demand, minimizing waste and interruptions. This method improves efficiency and predictability compared to traditional project timeline approaches, enabling steady progress and better resource utilization.

Last Planner System (LPS)

The Last Planner System (LPS) revolutionizes traditional project timelines by emphasizing collaborative planning and continuous workflow improvement, significantly reducing project delays and enhancing productivity in lean construction scheduling. Implementing LPS aligns project milestones with real-time capabilities, ensuring more reliable scheduling, minimized waste, and optimized resource utilization throughout the construction process.

Constraint Log

A Constraint Log in Lean Construction Scheduling systematically identifies and tracks all project limitations affecting workflow, enabling proactive resolution to maintain efficient progress within tight project timelines. Unlike traditional project timelines, which often react to delays, Lean methodologies use the Constraint Log to continuously optimize scheduling, minimize bottlenecks, and enhance overall construction productivity.

Buffer Management

Buffer management in Lean Construction Scheduling enhances traditional project timelines by strategically allocating time buffers to critical tasks, enabling real-time monitoring and adjustment of workflow disruptions. This approach reduces project delays and improves overall schedule reliability compared to conventional linear timeline methods.

Phase Scheduling

Phase scheduling in lean construction optimizes project timelines by breaking the workflow into manageable segments that enhance collaboration and reduce waste. This method contrasts traditional project timelines by emphasizing continuous flow and precise timing, improving overall efficiency and minimizing delays.

Milestone Alignment

Milestone alignment in lean construction scheduling improves project timeline accuracy by integrating continuous workflow optimization and real-time data feedback. This method reduces delays and enhances coordination among stakeholders, ensuring timely delivery and resource efficiency.

Collaborative Scheduling

Collaborative scheduling in lean construction enhances project timelines by integrating real-time input from all stakeholders, reducing delays through synchronized workflows and continuous progress monitoring. This approach minimizes waste and optimizes resource allocation, ensuring projects stay on schedule and within budget.

Just-in-Time Sequencing

Project Timeline in construction often follows a linear sequence with fixed milestones, whereas Lean Construction Scheduling emphasizes Just-in-Time sequencing to minimize waste and enhance efficiency by synchronizing tasks precisely when needed. Implementing Just-in-Time sequencing reduces inventory costs and prevents resource idle time, leading to streamlined workflows and improved project delivery times.

Real-Time Schedule Analytics

Real-Time Schedule Analytics in Lean Construction Scheduling enables dynamic project timeline adjustments by continuously monitoring progress and identifying delays, optimizing resource allocation and minimizing downtime. This approach enhances productivity compared to traditional static project timelines by integrating real-time data, ensuring more accurate forecasting and timely decision-making.

Project Timeline vs Lean Construction Scheduling Infographic

industrydif.com

industrydif.com