Additive manufacturing enhances defense supply chain resilience by enabling on-demand production of critical components, reducing dependency on traditional logistics and lengthy lead times. This technology supports rapid prototyping and decentralized manufacturing, which minimizes stockpile requirements and adapts swiftly to changing operational needs. In contrast, conventional supply chains often face vulnerabilities due to complex global sourcing, transportation risks, and inventory management challenges.

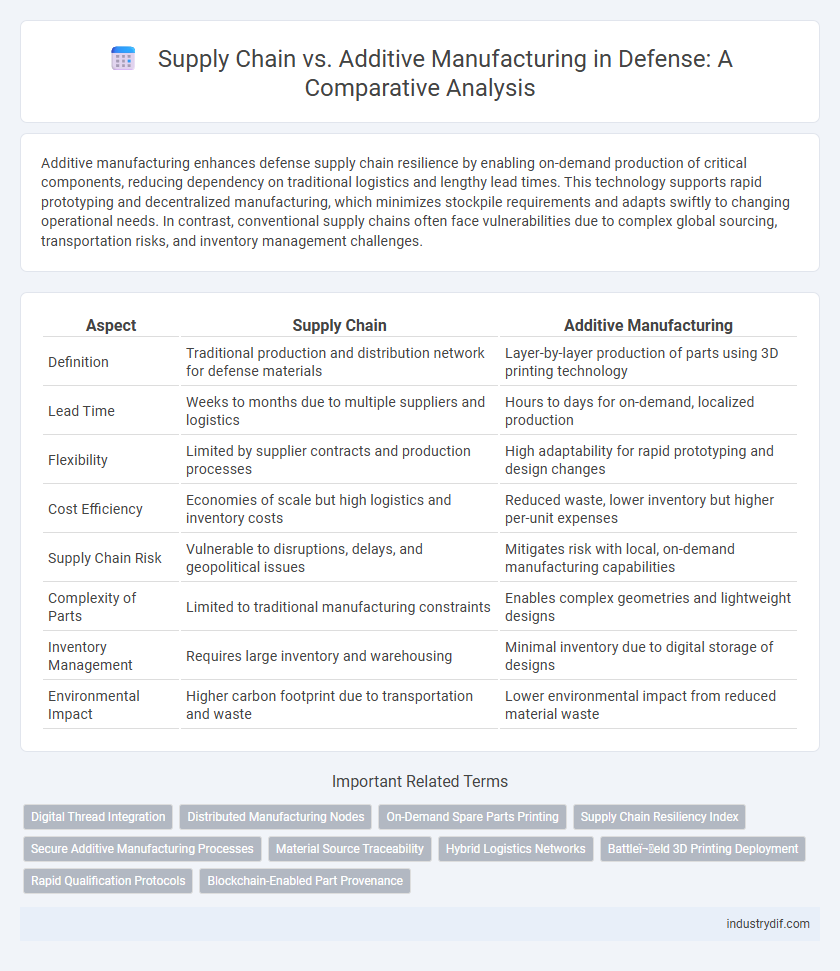

Table of Comparison

| Aspect | Supply Chain | Additive Manufacturing |

|---|---|---|

| Definition | Traditional production and distribution network for defense materials | Layer-by-layer production of parts using 3D printing technology |

| Lead Time | Weeks to months due to multiple suppliers and logistics | Hours to days for on-demand, localized production |

| Flexibility | Limited by supplier contracts and production processes | High adaptability for rapid prototyping and design changes |

| Cost Efficiency | Economies of scale but high logistics and inventory costs | Reduced waste, lower inventory but higher per-unit expenses |

| Supply Chain Risk | Vulnerable to disruptions, delays, and geopolitical issues | Mitigates risk with local, on-demand manufacturing capabilities |

| Complexity of Parts | Limited to traditional manufacturing constraints | Enables complex geometries and lightweight designs |

| Inventory Management | Requires large inventory and warehousing | Minimal inventory due to digital storage of designs |

| Environmental Impact | Higher carbon footprint due to transportation and waste | Lower environmental impact from reduced material waste |

Overview of Supply Chain in Defense Industry

The defense industry's supply chain integrates multiple tiers of suppliers, logistics providers, and manufacturers to ensure timely delivery of critical components and materials. It emphasizes stringent quality control, security protocols, and risk management to maintain operational readiness and mission-critical reliability. Complex global networks face challenges from geopolitical factors, regulatory compliance, and fluctuating demand, making supply chain resilience crucial for defense capabilities.

Introduction to Additive Manufacturing in Defense

Additive manufacturing in defense revolutionizes supply chain management by enabling rapid production of complex parts directly at or near the point of use, significantly reducing lead times and dependence on traditional logistics. This technology allows for on-demand manufacturing of critical components, enhancing operational readiness and reducing inventory costs. Its capability to produce lightweight, durable parts supports advanced defense systems while minimizing the vulnerabilities inherent in extended supply chains.

Key Differences Between Traditional Supply Chains and Additive Manufacturing

Traditional supply chains rely on complex logistics, multiple suppliers, and extended lead times for parts manufacturing, often causing delays in defense equipment readiness. Additive manufacturing streamlines production by enabling on-demand, localized fabrication of components using 3D printing technologies, reducing dependency on external suppliers and inventory. This approach enhances flexibility, decreases production costs, and accelerates maintenance and repair cycles critical for defense operations.

Impact on Production Lead Times

Additive manufacturing significantly reduces production lead times by enabling on-demand fabrication of complex components directly at or near the point of use, bypassing traditional supply chain delays related to sourcing and logistics. In contrast, conventional supply chains often experience extended lead times due to multiple tiers of suppliers and transportation bottlenecks, which can hinder rapid deployment in defense operations. This streamlined production capability enhances responsiveness and operational readiness in defense manufacturing environments.

Cost Efficiency: Supply Chain vs Additive Manufacturing

Supply chain logistics in defense often involve high costs due to transportation, inventory holding, and lengthy procurement cycles, driving up total lifecycle expenses. Additive manufacturing eliminates many supply chain complexities by enabling on-demand, localized production, drastically reducing storage and shipping costs. This cost efficiency is critical for defense sectors needing rapid, flexible responses while minimizing budget overruns associated with traditional supply chains.

Enhancing Operational Readiness with Additive Manufacturing

Additive manufacturing significantly enhances operational readiness by enabling rapid production of critical defense components directly on-site, reducing dependency on traditional supply chains vulnerable to disruptions. This technology facilitates on-demand manufacturing, allowing military units to quickly replace or repair equipment without waiting for long lead times associated with conventional logistics. Integration of additive manufacturing within defense supply chains streamlines maintenance processes and ensures continuous mission capability under dynamic operational conditions.

Security and Intellectual Property Concerns

Supply chain vulnerabilities in defense manufacturing expose critical components to risks of interception and tampering, jeopardizing national security and intellectual property integrity. Additive manufacturing offers localized production capabilities that reduce dependency on extended supply chains, thereby minimizing exposure to counterfeit parts and data breaches. However, protecting digital design files from cyber theft and unauthorized replication remains a significant challenge requiring robust encryption and secure access protocols.

Scalability and Flexibility in Defense Manufacturing

Additive manufacturing enables rapid prototyping and on-demand production, offering unparalleled flexibility to adapt designs and meet evolving defense requirements. Supply chain processes, while traditionally scalable, often face bottlenecks from global dependencies and long lead times, hindering agility in urgent scenarios. Leveraging additive manufacturing enhances scalability by localizing production, reducing reliance on complex logistics, and supporting customized solutions critical for defense manufacturing resilience.

Integration Challenges and Solutions

Supply chain integration in defense faces challenges such as lead time delays, supplier reliability, and complex logistics that hinder rapid deployment. Additive manufacturing offers on-demand production and reduced dependency on traditional suppliers but requires overcoming issues like material certification, standardization, and quality assurance. Solutions include developing hybrid supply models, establishing rigorous validation protocols, and investing in digital supply chain platforms to synchronize additive manufacturing with conventional logistics networks.

Future Trends: Evolving Defense Manufacturing Strategies

Future trends in defense manufacturing highlight a shift towards integrating additive manufacturing with traditional supply chain models to enhance agility and reduce lead times. Advanced 3D printing enables on-demand production of complex, mission-critical components, minimizing dependency on lengthy logistics and potential supply chain disruptions. This convergence supports a resilient and adaptive defense manufacturing strategy, vital for rapid response in dynamic operational environments.

Related Important Terms

Digital Thread Integration

Digital thread integration in defense enhances supply chain efficiency by enabling real-time data exchange and traceability across additive manufacturing processes, reducing lead times and improving component quality. This seamless connectivity supports agile logistics and predictive maintenance, vital for mission-critical operations and rapid deployment.

Distributed Manufacturing Nodes

Distributed manufacturing nodes in defense supply chains enhance resilience by decentralizing production, reducing dependency on long logistics lines, and enabling rapid, on-demand additive manufacturing of critical components. This approach mitigates supply chain disruptions by allowing localized fabrication of mission-essential parts, ensuring operational continuity and agility in dynamic combat environments.

On-Demand Spare Parts Printing

On-demand spare parts printing through additive manufacturing enhances defense supply chains by reducing lead times and minimizing inventory costs for critical components. This capability ensures rapid replacement of mission-essential parts directly at deployment sites, improving operational readiness and resilience.

Supply Chain Resiliency Index

The Supply Chain Resiliency Index measures the ability of defense logistics to withstand and recover from disruptions, offering critical insights into supply chain vulnerabilities compared to additive manufacturing's on-demand production capabilities. Enhancing the index through diversified sourcing and real-time tracking improves mission readiness by mitigating risks inherent in traditional supply chains.

Secure Additive Manufacturing Processes

Secure additive manufacturing processes enhance defense supply chain resilience by enabling on-demand, localized production of critical components, reducing dependency on extended, vulnerable logistics networks. Implementing stringent cybersecurity protocols and real-time quality controls within additive manufacturing ensures the integrity and confidentiality of sensitive defense designs throughout the production cycle.

Material Source Traceability

Supply chain management in defense relies heavily on rigid material source traceability to prevent counterfeit parts and ensure operational integrity, utilizing serialization and blockchain technologies to track components from origin to deployment. In contrast, additive manufacturing enables localized production with digital blueprints, enhancing traceability through embedded metadata and real-time monitoring of material composition, reducing dependency on complex supply chains.

Hybrid Logistics Networks

Hybrid logistics networks in defense integrate traditional supply chain systems with additive manufacturing, enabling rapid, on-demand production of critical components at or near the point of use. This approach reduces lead times, lowers inventory costs, and enhances operational resilience by combining centralized manufacturing efficiencies with decentralized, agile additive capabilities.

Battlefield 3D Printing Deployment

Battlefield 3D printing deployment transforms defense logistics by enabling on-demand additive manufacturing of critical components close to combat zones, significantly reducing supply chain vulnerabilities and lead times. This innovation enhances operational readiness and resilience by providing rapid prototyping and repair capabilities directly at the point of need in austere environments.

Rapid Qualification Protocols

Rapid qualification protocols in defense supply chains enable faster validation of additive manufacturing processes, significantly reducing lead times for critical components. Integrating these protocols ensures consistent quality and reliability while streamlining certification procedures essential for mission-critical deployments.

Blockchain-Enabled Part Provenance

Blockchain-enabled part provenance enhances supply chain transparency and security by providing immutable, real-time tracking of components in defense additive manufacturing. This technology ensures authenticated origin and lifecycle data of critical parts, reducing counterfeit risks and improving maintenance decision-making.

Supply Chain vs Additive Manufacturing Infographic

industrydif.com

industrydif.com