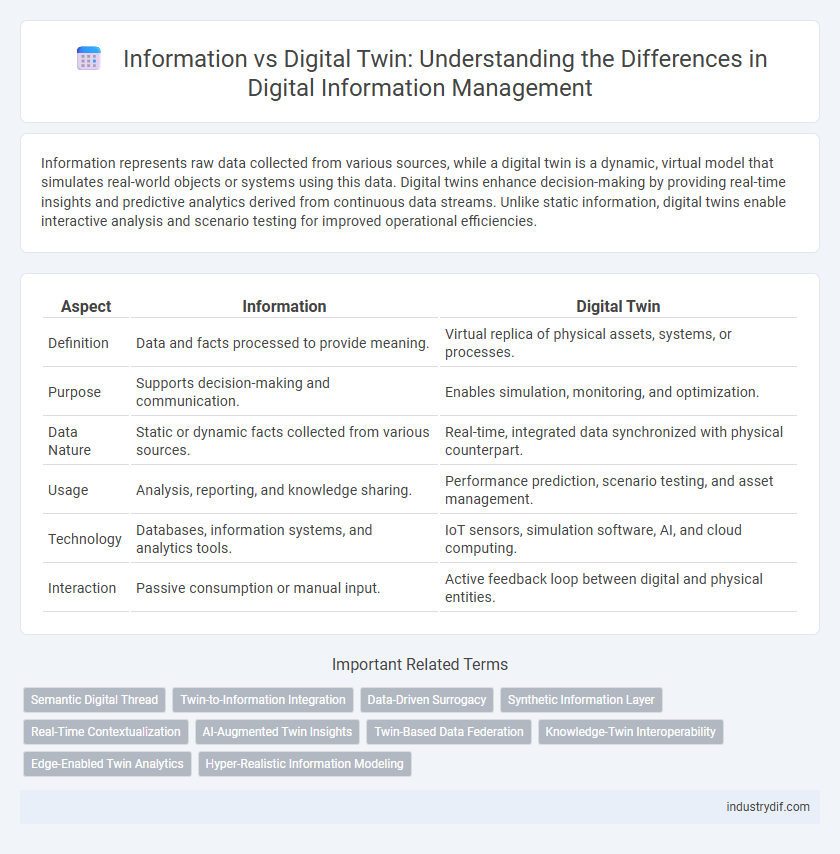

Information represents raw data collected from various sources, while a digital twin is a dynamic, virtual model that simulates real-world objects or systems using this data. Digital twins enhance decision-making by providing real-time insights and predictive analytics derived from continuous data streams. Unlike static information, digital twins enable interactive analysis and scenario testing for improved operational efficiencies.

Table of Comparison

| Aspect | Information | Digital Twin |

|---|---|---|

| Definition | Data and facts processed to provide meaning. | Virtual replica of physical assets, systems, or processes. |

| Purpose | Supports decision-making and communication. | Enables simulation, monitoring, and optimization. |

| Data Nature | Static or dynamic facts collected from various sources. | Real-time, integrated data synchronized with physical counterpart. |

| Usage | Analysis, reporting, and knowledge sharing. | Performance prediction, scenario testing, and asset management. |

| Technology | Databases, information systems, and analytics tools. | IoT sensors, simulation software, AI, and cloud computing. |

| Interaction | Passive consumption or manual input. | Active feedback loop between digital and physical entities. |

Understanding Information in Industrial Contexts

Understanding information in industrial contexts involves recognizing how raw data from sensors and machines is transformed into actionable insights that optimize operations and maintenance. Unlike a digital twin, which is a virtual replica of physical assets simulating real-time conditions, information refers to processed data supporting decision-making and predictive analytics. Effective use of information enhances asset management, reduces downtime, and drives efficiency in smart manufacturing environments.

What is a Digital Twin?

A Digital Twin is a dynamic virtual replica of a physical object, system, or process that uses real-time data to simulate its behavior and performance. Unlike static information, a Digital Twin continuously updates to reflect changes in the physical counterpart, enabling predictive analysis and improved decision-making. This integration of sensor data, machine learning, and simulation models allows businesses to optimize operations, reduce downtime, and enhance product development.

Key Differences Between Information and Digital Twin

Information refers to processed data that conveys meaning and supports decision-making, while a Digital Twin is a dynamic, virtual replication of a physical asset or system enabling real-time monitoring and simulation. Information typically exists as static or historical data sets, whereas Digital Twins integrate real-time sensor data to provide continuous updates and predictive insights. The key difference lies in the Digital Twin's ability to emulate and interact with its physical counterpart, offering a more comprehensive and actionable understanding beyond traditional information.

Data Representation vs. Virtual Modeling

Information primarily involves data representation, emphasizing the organization, storage, and communication of raw facts or processed data. In contrast, a Digital Twin integrates virtual modeling by creating dynamic, real-time simulations of physical objects or systems, enabling predictive analysis and interaction. While information forms the foundational dataset, digital twins transform this data into actionable insights through advanced visualization and behavioral replication.

Real-time Data Usage in Information and Digital Twins

Information systems leverage real-time data to provide timely insights, enabling dynamic decision-making and operational efficiency. Digital twins integrate continuous streams of real-time data to create virtual replicas of physical assets, allowing for predictive analysis and proactive maintenance. The real-time data usage in digital twins enhances simulation accuracy and supports adaptive system management beyond traditional information processing.

Role of Sensors in Data and Digital Twin Creation

Sensors play a critical role in capturing real-time data essential for the creation and accuracy of digital twins, enabling precise modeling of physical assets. They continuously monitor variables such as temperature, pressure, and motion, providing the raw data necessary for digital twins to simulate, analyze, and predict system behaviors. High-quality sensor data ensures digital twins reflect actual conditions, supporting improved decision-making and operational efficiency.

Integration with Industrial IoT Systems

Information serves as the foundational data that supports Industrial IoT systems, while Digital Twins act as dynamic virtual representations of physical assets, processes, or systems within these environments. Integration of Digital Twins with Industrial IoT enables real-time monitoring, predictive maintenance, and enhanced decision-making by continuously synchronizing data streams from sensors and connected devices. This fusion maximizes operational efficiency, reduces downtime, and drives smarter automation strategies across industrial sectors.

Benefits of Digital Twins Over Traditional Information

Digital Twins offer real-time data integration and dynamic simulation, enabling precise monitoring and predictive maintenance beyond static information records. Their ability to replicate physical assets digitally enhances decision-making accuracy and operational efficiency in complex systems. Unlike traditional information, Digital Twins provide continuous updates and interactive insights, facilitating proactive problem-solving and innovation.

Challenges in Implementing Digital Twins vs. Information Management

Implementing digital twins faces challenges such as high data integration complexity, real-time synchronization requirements, and substantial computational resources, which contrasts with traditional information management's emphasis on data storage and retrieval. Digital twins demand precise modeling of physical assets and continuous updating to reflect dynamic changes, increasing implementation costs and technical expertise needs. Information management systems prioritize structured data handling, while digital twins require advanced simulation, data analytics, and interoperability across IoT devices and platforms.

Future Trends in Industrial Information and Digital Twin Technologies

Future trends in industrial information emphasize real-time data integration and advanced analytics to enhance decision-making and operational efficiency. Digital twin technologies are evolving with increased virtualization, AI-driven simulations, and predictive maintenance capabilities, enabling adaptive and autonomous industrial systems. The convergence of IoT, edge computing, and machine learning accelerates the development of intelligent digital twins, fostering smarter manufacturing and resource optimization.

Related Important Terms

Semantic Digital Thread

Semantic Digital Thread integrates detailed information across product lifecycle stages, enabling real-time data synchronization and enhancing traceability. Unlike traditional digital twins, it emphasizes semantic interoperability to connect disparate information sources into a cohesive, context-rich digital representation.

Twin-to-Information Integration

Twin-to-information integration leverages real-time data from digital twins to enhance decision-making, enabling dynamic system monitoring and predictive analytics. This seamless synchronization between virtual models and physical assets transforms raw sensor inputs into actionable insights, optimizing operational efficiency and reducing downtime.

Data-Driven Surrogacy

Digital Twin technology leverages data-driven surrogacy by creating real-time virtual replicas of physical assets, enabling continuous monitoring and predictive analytics through sensor-generated data. Unlike traditional information systems that store static data, Digital Twins integrate dynamic data streams to simulate and optimize operational performance in complex environments.

Synthetic Information Layer

The Synthetic Information Layer integrates diverse data sources to create a unified, dynamic representation that goes beyond static information by enabling real-time simulation and predictive analytics. Unlike traditional information systems, this layer synthesizes raw data into actionable insights, forming the core of digital twin technology for enhanced decision-making.

Real-Time Contextualization

Real-time contextualization distinguishes Information from a Digital Twin by enabling dynamic data integration and live environment simulation, which enhances decision-making accuracy and operational efficiency. Unlike static information, Digital Twins provide continuous updates reflecting real-world changes, supporting predictive analytics and proactive interventions.

AI-Augmented Twin Insights

AI-augmented digital twins enhance traditional information models by integrating real-time data analytics and machine learning algorithms, enabling predictive insights and dynamic simulations. This fusion of information and AI-driven digital twins facilitates smarter decision-making and optimized operational efficiency across industries.

Twin-Based Data Federation

Twin-based data federation integrates real-time sensor data and historical information within a digital twin platform, enabling synchronized, accurate modeling of physical assets. This approach enhances decision-making by harmonizing heterogeneous data sources into a unified, semantic-rich representation, improving operational efficiency and predictive analytics.

Knowledge-Twin Interoperability

Information serves as the foundational data enabling the creation and functioning of Digital Twins, while Knowledge-Twin Interoperability ensures seamless integration and real-time synchronization between a knowledge representation layer and the physical asset's digital counterpart. Effective interoperability frameworks leverage standardized ontologies and semantic models to facilitate accurate data exchange, enhancing predictive analytics and decision-making processes in complex systems.

Edge-Enabled Twin Analytics

Edge-enabled twin analytics leverages real-time data processing at the network edge to enhance the accuracy and responsiveness of digital twins, enabling immediate insights and decision-making. Unlike raw information, edge analytics in digital twins integrates sensor data, machine learning models, and contextual intelligence to optimize operational efficiency and predictive maintenance in industrial environments.

Hyper-Realistic Information Modeling

Hyper-realistic information modeling enhances digital twin technology by creating ultra-detailed, accurate virtual replicas of physical assets and processes. This advanced approach captures dynamic, real-time data and integrates semantic information to enable precise simulations, predictive analytics, and improved decision-making.

Information vs Digital Twin Infographic

industrydif.com

industrydif.com