Cut and fill mining offers precise excavation control, allowing selective ore extraction with minimal dilution, optimizing overall resource recovery. Sensor-based ore sorting enhances efficiency by rapidly distinguishing ore from waste before milling, reducing processing costs and energy consumption. Combining both methods can maximize productivity and improve operational sustainability in modern mining projects.

Table of Comparison

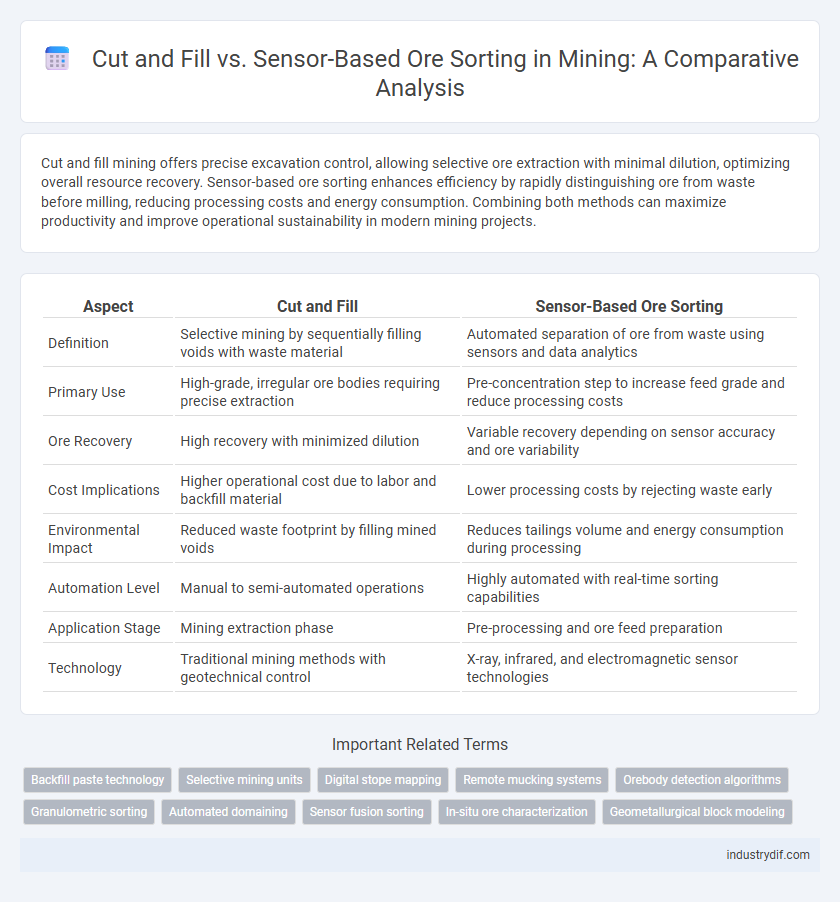

| Aspect | Cut and Fill | Sensor-Based Ore Sorting |

|---|---|---|

| Definition | Selective mining by sequentially filling voids with waste material | Automated separation of ore from waste using sensors and data analytics |

| Primary Use | High-grade, irregular ore bodies requiring precise extraction | Pre-concentration step to increase feed grade and reduce processing costs |

| Ore Recovery | High recovery with minimized dilution | Variable recovery depending on sensor accuracy and ore variability |

| Cost Implications | Higher operational cost due to labor and backfill material | Lower processing costs by rejecting waste early |

| Environmental Impact | Reduced waste footprint by filling mined voids | Reduces tailings volume and energy consumption during processing |

| Automation Level | Manual to semi-automated operations | Highly automated with real-time sorting capabilities |

| Application Stage | Mining extraction phase | Pre-processing and ore feed preparation |

| Technology | Traditional mining methods with geotechnical control | X-ray, infrared, and electromagnetic sensor technologies |

Introduction to Cut and Fill Mining

Cut and fill mining is a selective underground mining method that involves excavating ore in horizontal slices while filling the voids with waste material, ensuring ground stability and allowing precise ore extraction. This method is particularly effective in irregular or steeply dipping ore bodies, reducing dilution and maximizing ore recovery. Sensor-based ore sorting, by contrast, uses advanced detection technologies to separate valuable minerals from waste rock at the surface, enhancing pre-concentration but relying on ore exposed via traditional mining methods like cut and fill for initial access.

Fundamentals of Sensor-based Ore Sorting

Sensor-based ore sorting utilizes advanced technologies such as X-ray transmission, near-infrared spectroscopy, and laser-induced breakdown spectroscopy to identify and separate valuable minerals from waste rock. This method enhances processing efficiency by enabling early-stage waste rejection, reducing transportation and milling costs compared to traditional cut and fill methods. Fundamental to sensor-based ore sorting is the real-time analysis of ore properties, which allows for selective extraction and optimization of resource recovery in mining operations.

Comparative Overview: Cut and Fill vs Sensor-based Ore Sorting

Cut and fill mining offers precise selective extraction by filling voids with waste material, enhancing ground stability but involves higher labor and material costs compared to sensor-based ore sorting. Sensor-based ore sorting employs advanced technologies such as X-ray fluorescence and optical sensors to rapidly and economically distinguish ore from waste, improving processing efficiency and reducing dilution. While cut and fill ensures minimal ore loss in complex vein structures, sensor-based sorting excels in large-scale operations with consistent ore feed and offers scalability with reduced environmental impact.

Geological Suitability for Each Method

Cut and fill mining is best suited for irregular, high-grade ore bodies in geologically complex environments, enabling selective extraction and ground support in variable rock conditions. Sensor-based ore sorting excels in homogenous ore deposits with distinct mineralogical differences, allowing precise separation of valuable minerals from waste based on physical or chemical properties. Geological formations with consistent textures and clear grade boundaries enhance the effectiveness of sensor-based sorting, while heterogeneous and structurally challenging geologies demand the adaptability of cut and fill techniques.

Operational Workflow and Process Differences

Cut and fill mining involves manually excavating ore in controlled increments, filling voids with waste material to maintain ground stability, which requires extensive drilling, blasting, and backfilling operations. Sensor-based ore sorting uses real-time data acquisition technologies such as X-ray transmission and near-infrared spectroscopy to separate ore from waste on conveyor belts, enabling rapid, automated processing before milling. The operational workflow of cut and fill centers on sequential excavation and support, while sensor-based sorting streamlines ore grade control and reduces material handling through advanced sensor integration.

Cost Implications and Economic Feasibility

Cut and fill mining incurs high operational costs due to extensive ground support, backfilling, and slower advancement rates, impacting overall economic feasibility. Sensor-based ore sorting reduces processing of waste material, lowers energy consumption, and decreases transportation expenses, significantly improving cost efficiency and profitability. Evaluating site-specific ore characteristics and capital investment requirements is crucial for determining the most cost-effective method between cut and fill and sensor-based ore sorting.

Environmental Considerations and Sustainability

Cut and fill mining generates substantial waste rock, leading to significant land disturbance and increased environmental footprint, while sensor-based ore sorting minimizes waste by pre-concentration of ore, enhancing resource efficiency. Sensor-based sorting reduces energy consumption and water usage compared to traditional cut and fill methods, lowering greenhouse gas emissions and promoting sustainable mining operations. Implementing sensor-based ore sorting supports circular economy principles by reducing tailings volume and enabling more precise extraction, thus improving environmental stewardship in mining projects.

Productivity and Ore Recovery Rates

Cut and fill mining offers high ore recovery rates by selectively excavating high-grade zones but often experiences lower productivity due to labor-intensive processes and slower cycle times. Sensor-based ore sorting significantly enhances productivity through rapid, automated separation of ore from waste, although its ore recovery rates depend on sensor accuracy and ore variability. Integrating sensor-based sorting with cut and fill techniques can optimize overall mining efficiency by balancing precise material extraction with accelerated processing speeds.

Technological Advancements and Future Trends

Cut and fill mining demonstrates advancements in precise ore extraction through controlled backfilling and selective mining, enhancing resource recovery and minimizing dilution. Sensor-based ore sorting utilizes real-time data analysis with technologies like X-ray transmission, hyperspectral imaging, and machine learning algorithms to increase grade control and reduce processing costs. Future trends emphasize integrating AI-driven sensor arrays and automation to optimize ore separation efficiency and enable more sustainable mining operations.

Selecting the Optimal Method for Site Conditions

Cut and fill mining offers precise control and flexibility in irregular ore bodies, making it suitable for complex site conditions with variable geology and limited space. Sensor-based ore sorting enhances efficiency by pre-concentrating ore and reducing waste, particularly effective in high-grade, fragmented deposits with consistent mineralogy. Evaluating site-specific factors such as ore variability, environmental impact, and operational costs is crucial in selecting the optimal extraction method.

Related Important Terms

Backfill paste technology

Cut and fill mining utilizes backfill paste technology to stabilize voids and enhance ground support by filling excavated areas with a cemented mixture of tailings and binder, improving safety and ore recovery in irregular ore bodies. Sensor-based ore sorting, meanwhile, enhances grade control by selectively separating ore from waste pre-processing, but relies on precise sensor calibration and ore characterization to maximize efficiency, with backfill paste playing a crucial role in sustainable waste management post-extraction.

Selective mining units

Cut and fill mining enables precise control over selective mining units by systematically excavating ore in discrete, manageable sections, minimizing dilution and preserving high-grade zones. Sensor-based ore sorting enhances selectivity by rapidly identifying and separating ore from waste material at the processing stage, optimizing recovery and reducing the volume of material sent to the mill.

Digital stope mapping

Digital stope mapping enhances cut and fill mining by providing precise 3D models of the underground voids, enabling optimized waste removal and ore extraction. Sensor-based ore sorting leverages advanced optical and X-ray sensors to improve ore grade control before processing, complementing digital mapping for higher operational efficiency.

Remote mucking systems

Cut and fill mining offers precise selective extraction but involves labor-intensive remote mucking systems with slower cycle times, whereas sensor-based ore sorting integrates real-time material characterization for remote mucking automation, enhancing efficiency and reducing dilution. Implementing advanced sensor technologies like X-ray transmission and hyperspectral imaging enables remote mucking systems to optimize ore segregation, leading to improved resource recovery and operational cost savings.

Orebody detection algorithms

Orebody detection algorithms in cut and fill mining rely heavily on geological modeling and manual sampling, which can be time-consuming and less precise compared to sensor-based ore sorting that utilizes real-time data from X-ray transmission, laser-induced breakdown spectroscopy, and near-infrared sensors to rapidly discriminate ore from waste. Sensor-based sorting algorithms integrate machine learning and multispectral analysis to enhance ore grade estimation accuracy and increase recovery rates by dynamically adapting to ore variability during the processing phase.

Granulometric sorting

Cut and fill mining offers precise excavation suited for irregular ore bodies but often results in mixed granulometric material requiring secondary processing. Sensor-based ore sorting enhances granulometric sorting by selectively separating ore particles based on size and compositional sensors, improving grade control and reducing dilution before milling.

Automated domaining

Cut and fill mining offers precise ore extraction within complex geological structures but relies heavily on manual sampling and domain interpretation, limiting automation potential. Sensor-based ore sorting enhances automated domaining by enabling real-time, high-resolution ore characterization, reducing waste and improving resource recovery through advanced data analytics and machine learning integration.

Sensor fusion sorting

Sensor fusion sorting in mining integrates multiple sensor technologies such as X-ray, near-infrared, and optical sensors to enhance ore grade control and reduce dilution compared to traditional cut and fill methods. This advanced approach enables real-time data processing and precise separation of ore from waste, significantly improving operational efficiency and reducing processing costs.

In-situ ore characterization

Cut and fill mining relies on direct in-situ ore characterization through geological mapping and sampling to guide selective excavation, minimizing dilution and maximizing ore recovery. Sensor-based ore sorting enhances this process by integrating real-time, non-invasive detection technologies such as X-ray fluorescence and hyperspectral imaging, enabling more precise ore grade control before processing.

Geometallurgical block modeling

Cut and fill mining integrates geometallurgical block modeling to optimize ore extraction by selectively removing mineralized zones, improving ore grade control and reducing dilution. Sensor-based ore sorting leverages real-time geometallurgical data for precise ore characterization, enabling efficient pre-concentration and enhancing overall processing efficiency in mineral recovery.

Cut and fill vs Sensor-based ore sorting Infographic

industrydif.com

industrydif.com