Underground mining and sublevel caving are distinct methods used for extracting minerals beneath the Earth's surface, with the former involving tunnels and shafts to reach ore bodies and the latter relying on controlled caving of ore to enable recovery. Underground mining offers greater precision and control, making it suitable for high-grade ore deposits with complex geology, while sublevel caving is more cost-effective for large, massive ore bodies but with lower selectivity. Selecting between these techniques depends on ore body geometry, rock stability, and production targets to optimize recovery and operational efficiency.

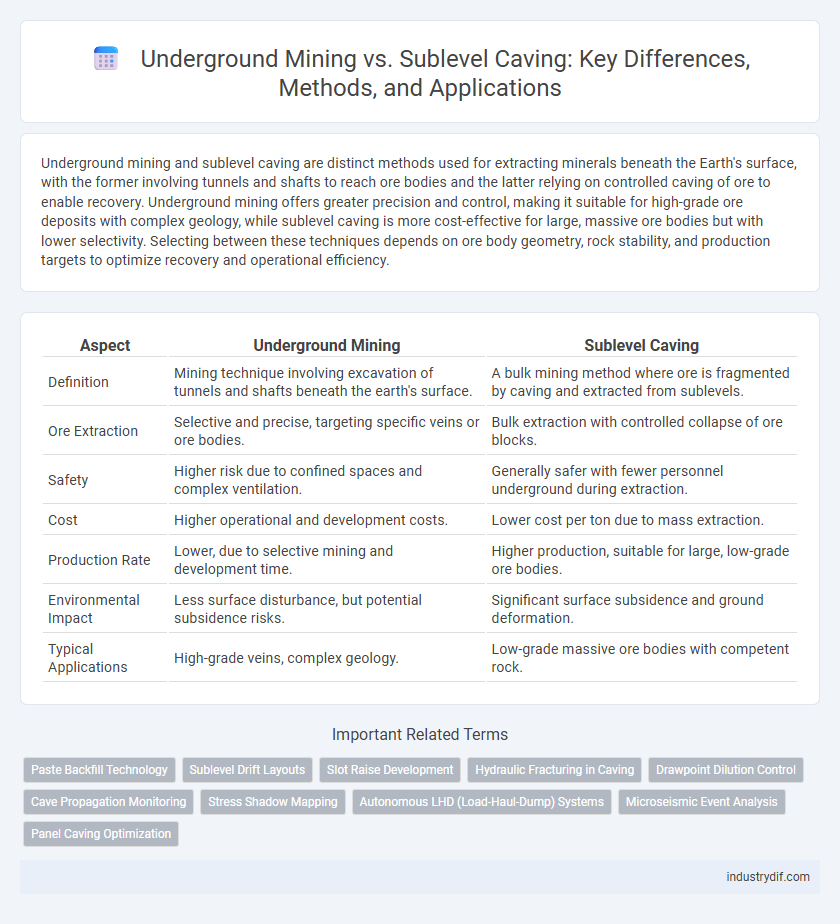

Table of Comparison

| Aspect | Underground Mining | Sublevel Caving |

|---|---|---|

| Definition | Mining technique involving excavation of tunnels and shafts beneath the earth's surface. | A bulk mining method where ore is fragmented by caving and extracted from sublevels. |

| Ore Extraction | Selective and precise, targeting specific veins or ore bodies. | Bulk extraction with controlled collapse of ore blocks. |

| Safety | Higher risk due to confined spaces and complex ventilation. | Generally safer with fewer personnel underground during extraction. |

| Cost | Higher operational and development costs. | Lower cost per ton due to mass extraction. |

| Production Rate | Lower, due to selective mining and development time. | Higher production, suitable for large, low-grade ore bodies. |

| Environmental Impact | Less surface disturbance, but potential subsidence risks. | Significant surface subsidence and ground deformation. |

| Typical Applications | High-grade veins, complex geology. | Low-grade massive ore bodies with competent rock. |

Overview of Underground Mining Methods

Underground mining methods, including sublevel caving, are essential techniques used to extract mineral deposits located deep beneath the earth's surface. Sublevel caving involves creating sublevels in the ore body, allowing gravity to assist in the controlled collapse of the ore, facilitating efficient extraction and minimizing surface impact. Compared to other underground mining methods such as cut and fill or room and pillar, sublevel caving offers higher production rates and is well-suited for large, steeply dipping ore bodies.

Introduction to Sublevel Caving

Sublevel caving is an underground mining method that exploits large, low-grade ore bodies by systematically drilling and blasting from multiple sublevels within a vertical or steeply inclined ore deposit. This technique allows controlled caving of the ore, where broken rock collapses under gravity, facilitating continuous extraction while maintaining ground stability. Compared to traditional underground mining, sublevel caving enhances operational efficiency and reduces development costs by minimizing extensive shaft sinking and drift excavation.

Key Differences Between Underground Mining and Sublevel Caving

Underground mining refers to a broad category of mining techniques where mineral extraction occurs beneath the earth's surface, often using methods such as cut-and-fill, room-and-pillar, or block caving. Sublevel caving is a specific underground mining method that involves systematic fragmentation of ore by drilling and blasting from sublevels, allowing the broken ore to cave and be collected from draw points below. Key differences include sublevel caving's reliance on gravity-induced cave fragmentation and continuous ore flow, contrasting with other underground mining methods that may require more labor-intensive support and stoping techniques.

Geological Conditions Favoring Each Method

Underground mining suits hard rock formations with stable geology, allowing safe excavation of narrow veins and irregular ore bodies. Sublevel caving thrives in massive, steeply dipping ore deposits with competent roof rock that facilitates controlled caving and large-scale extraction. Geological stability and ore body geometry dictate the choice between the selective precision of underground mining and the high-volume efficiency of sublevel caving.

Ore Recovery Rates and Dilution Comparison

Underground mining methods such as sublevel caving typically achieve higher ore recovery rates, often exceeding 70-80%, compared to selective underground methods that target specific ore zones with lower recovery rates around 50-60%. However, sublevel caving tends to experience increased dilution due to its bulk mining approach, with dilution percentages ranging from 15-25%, whereas more selective underground mining can maintain dilution under 10%. Optimizing mining method selection depends on balancing ore recovery efficiency against acceptable dilution levels to maximize profitability and resource utilization.

Safety Considerations in Both Mining Methods

Underground mining involves intricate tunnel systems requiring rigorous ventilation and rock support to mitigate collapse risks, while sublevel caving leverages controlled caving of ore bodies that can pose challenges with ground stability and air quality. Safety protocols in underground mining emphasize hazard identification and continuous monitoring, whereas sublevel caving demands careful management of caving sequences to prevent unplanned collapses and ensure miner protection. Both methods necessitate advanced risk assessments and emergency preparedness plans tailored to their distinct operational hazards.

Equipment and Technology Requirements

Underground mining demands specialized equipment such as continuous miners, shuttle cars, and roof bolters to ensure efficient extraction and worker safety in confined spaces. Sublevel caving requires robust drilling rigs, large-scale loaders, and advanced ventilation systems to manage extensive cave-ins and material transport. Both methods leverage real-time monitoring technologies and automation to optimize operational efficiency and reduce risks.

Cost Analysis: Underground Mining vs Sublevel Caving

Cost analysis reveals that underground mining generally incurs higher operational expenses due to complex ventilation and ground support requirements, while sublevel caving offers cost efficiency through bulk mining and reduced labor intensity. Sublevel caving minimizes development costs by leveraging gravity for ore extraction, significantly lowering per tonne expenses compared to conventional underground methods. Economic evaluation must consider ore body geometry, dilution rates, and recovery factors, as these impact the overall cost-effectiveness of each mining technique.

Environmental Impact Assessment

Underground mining generally causes less surface disturbance compared to Sublevel caving, which involves significant ground subsidence affecting local ecosystems. Environmental Impact Assessments (EIA) for Sublevel caving must extensively evaluate risks of land deformation, groundwater contamination, and habitat disruption. Regulatory frameworks often require comprehensive monitoring programs to mitigate the elevated environmental risks associated with Sublevel caving operations.

Choosing the Optimal Mining Method for Your Deposit

Selecting the optimal mining method depends on ore body geometry, depth, and rock stability, with underground mining preferred for narrow, high-grade veins and sublevel caving suited for massive, low-grade deposits with competent hanging walls. Underground mining offers precise control and minimal surface disturbance, while sublevel caving maximizes extraction rates and reduces operational costs through controlled caving. Comprehensive geological surveys and economic evaluations ensure the chosen method aligns with safety, efficiency, and profitability targets.

Related Important Terms

Paste Backfill Technology

Paste backfill technology enhances underground mining by improving ground stability and allowing selective ore extraction, whereas sublevel caving primarily relies on gravity-induced fragmentation with less focus on backfill support. Integrating paste backfill in sublevel caving reduces surface subsidence and increases ore recovery by reinforcing mined-out voids.

Sublevel Drift Layouts

Sublevel drift layouts are integral to sublevel caving, allowing systematic access to ore zones through horizontal drifts spaced at regular vertical intervals, optimizing fragmentation and ore draw control. This contrasts with traditional underground mining methods, where drift layouts are less uniformly organized, resulting in varied extraction efficiency and stability management.

Slot Raise Development

Slot raise development in underground mining involves creating vertical or near-vertical openings to provide access, ventilation, and ore extraction routes, crucial for efficient sublevel caving operations. This method ensures controlled fragmentation and material flow between sublevels, optimizing ore recovery and minimizing surface disruption compared to traditional underground mining techniques.

Hydraulic Fracturing in Caving

Hydraulic fracturing in underground mining, particularly within sublevel caving operations, enhances ore fragmentation by creating controlled fractures that improve caveability and facilitate efficient material removal. This technique optimizes rock breakage, reduces dilution, and increases production rates compared to conventional blasting methods in sublevel caving environments.

Drawpoint Dilution Control

Drawpoint dilution control in underground mining is critical for maximizing ore recovery and minimizing waste extraction, with sublevel caving offering improved dilution management through controlled caving and systematic ore draw. Effective drawpoint design and monitoring in sublevel caving reduces ore loss and enhances grade control compared to conventional underground mining methods.

Cave Propagation Monitoring

Cave propagation monitoring in underground mining utilizes advanced geotechnical instrumentation, such as microseismic sensors and extensometers, to track the stability and collapse patterns within sublevel caving operations. Effective monitoring ensures precise control over cave advance rates and safety management by detecting rock mass movements and potential hazards in real-time, optimizing resource extraction and minimizing ground control risks.

Stress Shadow Mapping

Stress shadow mapping plays a crucial role in underground mining by visualizing stress redistribution around excavations, enabling safer design and operation. In sublevel caving, this technique helps predict caving progression and stress concentration zones, optimizing extraction sequences and minimizing ground control risks.

Autonomous LHD (Load-Haul-Dump) Systems

Autonomous LHD systems in underground mining enhance efficiency by providing precise material transport and reducing human risk, particularly in complex environments like sublevel caving. These systems optimize ore extraction by navigating unstable rock formations while increasing safety and operational continuity compared to traditional manual LHD operations.

Microseismic Event Analysis

Microseismic event analysis in underground mining provides critical data on rock mass behavior, enabling real-time monitoring of stress changes and fracture propagation. Sublevel caving generates a higher frequency of microseismic events compared to traditional underground mining, facilitating improved hazard prediction and controlled caving processes through detailed seismic event characterization.

Panel Caving Optimization

Panel caving offers enhanced ore recovery and operational efficiency compared to traditional underground mining methods by systematically collapsing ore panels to reduce dilution and improve fragmentation. Optimizing panel caving involves precise draw control and accurate geotechnical modeling to maximize production rates and minimize ground control risks.

Underground mining vs Sublevel caving Infographic

industrydif.com

industrydif.com