Surface mining involves the removal of large soil and rock layers to access minerals near the Earth's surface, offering high productivity but significant environmental disruption. Bioleaching uses microorganisms to extract metals from ores, providing an eco-friendly and cost-effective alternative with minimal landscape disturbance. While surface mining delivers rapid resource extraction, bioleaching is increasingly valued for sustainable mining practices and reduced ecological impact.

Table of Comparison

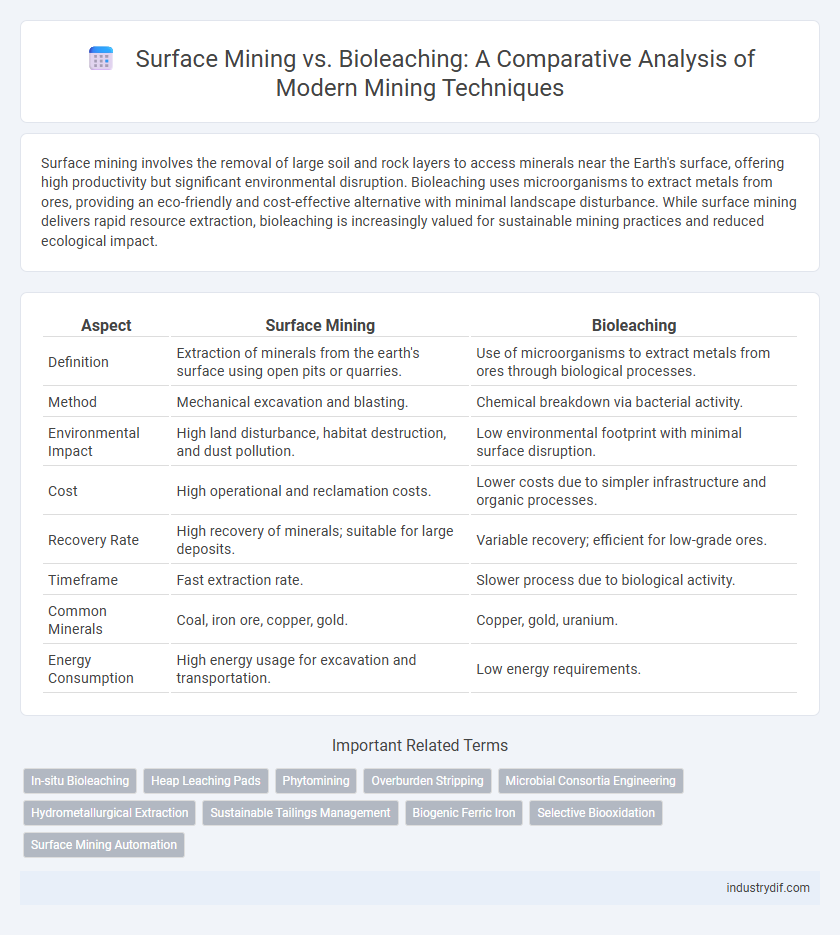

| Aspect | Surface Mining | Bioleaching |

|---|---|---|

| Definition | Extraction of minerals from the earth's surface using open pits or quarries. | Use of microorganisms to extract metals from ores through biological processes. |

| Method | Mechanical excavation and blasting. | Chemical breakdown via bacterial activity. |

| Environmental Impact | High land disturbance, habitat destruction, and dust pollution. | Low environmental footprint with minimal surface disruption. |

| Cost | High operational and reclamation costs. | Lower costs due to simpler infrastructure and organic processes. |

| Recovery Rate | High recovery of minerals; suitable for large deposits. | Variable recovery; efficient for low-grade ores. |

| Timeframe | Fast extraction rate. | Slower process due to biological activity. |

| Common Minerals | Coal, iron ore, copper, gold. | Copper, gold, uranium. |

| Energy Consumption | High energy usage for excavation and transportation. | Low energy requirements. |

Overview of Surface Mining and Bioleaching

Surface mining involves extracting minerals located near the Earth's surface by removing soil and rock layers, making it efficient for large, shallow mineral deposits like coal, iron, and copper. Bioleaching utilizes microorganisms to dissolve metals from ores, offering an environmentally friendly alternative for low-grade and complex ores, particularly in copper and gold extraction. Both methods optimize resource recovery but differ significantly in operational scale, environmental impact, and processing time.

Key Differences Between Surface Mining and Bioleaching

Surface mining involves the direct excavation of ore deposits from the earth's surface using heavy machinery, making it suitable for large, near-surface mineral seams. Bioleaching employs microorganisms to chemically extract metals such as copper and gold from low-grade ores through biological oxidation processes, reducing environmental impact. Key differences include the scale of operation, environmental footprint, and ore grade suitability, with surface mining enabling rapid extraction and bioleaching offering a more sustainable alternative for complex or lower-grade ores.

Environmental Impact: Surface Mining vs. Bioleaching

Surface mining disrupts large land areas, leading to habitat destruction, soil erosion, and contamination of water sources from runoff containing heavy metals. Bioleaching offers a more environmentally friendly alternative by utilizing microorganisms to extract metals with minimal land disturbance and reduced chemical pollution. This process lowers greenhouse gas emissions and preserves surrounding ecosystems compared to the extensive environmental footprint of surface mining.

Cost Comparison: Surface Mining vs. Bioleaching

Surface mining involves high upfront capital expenditure for equipment and infrastructure, resulting in substantial operational costs due to fuel and labor requirements. Bioleaching presents lower initial investment and reduced energy consumption, making it cost-effective for low-grade ores and smaller deposits. However, bioleaching's slower extraction rate may lead to longer project timelines, impacting overall economic feasibility compared to the faster, though more expensive, surface mining methods.

Efficiency and Recovery Rates in Extraction

Surface mining offers high extraction efficiency for large, near-surface ore deposits with recovery rates typically between 85% and 95%. Bioleaching provides a cost-effective alternative for low-grade ores, achieving recovery rates up to 90% by utilizing microbial processes to dissolve metals. Efficiency in surface mining depends on ore accessibility and scale, while bioleaching excels in environmental sustainability and processing complex sulfide minerals.

Applications in the Mining Industry

Surface mining is widely applied for large-scale extraction of coal, iron ore, and copper due to its cost-effectiveness and high productivity in shallow deposits. Bioleaching has gained prominence in the mining industry for processing low-grade ores and recovering metals such as gold, copper, and uranium through environmentally friendly microbial oxidation. Both methods complement each other, with surface mining serving primary extraction needs and bioleaching enhancing metal recovery in tailings and complex ores.

Safety Considerations and Workforce Requirements

Surface mining presents significant safety risks including exposure to dust, heavy machinery accidents, and slope failures, necessitating extensive training and protective equipment for workers. Bioleaching offers a safer alternative by utilizing microorganisms to extract metals, reducing the need for hazardous chemicals and heavy equipment operation, which limits direct human exposure to dangerous conditions. Workforce requirements for bioleaching emphasize microbiology and chemical engineering expertise, contrasting with surface mining's demand for skilled operators and rigorous physical safety protocols.

Technological Advances in Surface Mining and Bioleaching

Technological advances in surface mining include automated drilling systems, real-time ore grade sensors, and drone-based topographical mapping, significantly enhancing extraction efficiency and reducing environmental impact. Bioleaching has benefited from genetic engineering of microorganisms to improve metal recovery rates, alongside advancements in bioreactor design for scalable, controlled leaching processes. Integration of data analytics and remote monitoring systems optimizes both surface mining operations and bioleaching, enabling more precise resource management and predictive maintenance.

Regulatory and Compliance Challenges

Surface mining faces rigorous regulatory challenges related to land disturbance, habitat destruction, and waste management, requiring extensive environmental impact assessments and strict adherence to reclamation standards. Bioleaching, while considered more environmentally friendly, must comply with regulations governing the use of genetically modified organisms and the management of potentially toxic bioleach residues. Both techniques demand comprehensive monitoring and reporting to meet local and international mining laws and environmental protection guidelines.

Future Trends in Mining: Surface Methods vs. Bioleaching

Future trends in mining highlight a growing shift towards bioleaching due to its eco-friendly nature and cost-efficiency in extracting metals from low-grade ores. Surface mining remains dominant for large-scale mineral extraction, but advancements in biotechnology improve bioleaching's adaptability to diverse minerals and harsh environmental conditions. Integration of bioleaching with automated surface mining techniques promises enhanced recovery rates and reduced environmental impact.

Related Important Terms

In-situ Bioleaching

In-situ bioleaching involves using microorganisms to extract metals directly from ore bodies without traditional excavation, minimizing surface disruption compared to conventional surface mining techniques. This method enhances environmental sustainability by reducing waste generation, lowering energy consumption, and enabling the recovery of metals such as copper and gold from low-grade deposits.

Heap Leaching Pads

Heap leaching pads in surface mining provide a cost-effective method for extracting metals by stacking ore and applying chemical solutions, enabling efficient mineral recovery from low-grade ores. Bioleaching enhances heap leaching pads by using microorganisms to oxidize sulfide minerals, increasing metal extraction rates and reducing environmental impact compared to traditional chemical leaching methods.

Phytomining

Phytomining leverages hyperaccumulator plants to extract valuable metals from contaminated soils, offering an eco-friendly alternative to traditional surface mining that often leads to significant land disruption and habitat loss. Unlike bioleaching, which uses microorganisms to solubilize metals, phytomining harvests metal-rich biomass, providing a sustainable method to recover metals while simultaneously remediating soil pollution.

Overburden Stripping

Overburden stripping in surface mining involves the removal of large volumes of soil and rock to access mineral deposits, requiring heavy machinery and generating significant environmental disturbance. In contrast, bioleaching bypasses overburden stripping by using microorganisms to extract metals from low-grade ores, reducing the environmental footprint and surface disruption.

Microbial Consortia Engineering

Surface mining disrupts large land areas and generates substantial waste, whereas bioleaching employs microbial consortia engineering to enhance metal recovery by optimizing synergistic interactions among bacteria and archaea, leading to environmentally sustainable extraction processes. Advances in microbial consortia design improve bioleaching efficiency through tailored metabolic cooperation, accelerating metal solubilization from low-grade ores while minimizing ecological impact compared to traditional surface mining methods.

Hydrometallurgical Extraction

Surface mining physically removes ore deposits from the earth's surface, allowing direct access to minerals but generating large quantities of waste and environmental disturbance. Bioleaching, a hydrometallurgical extraction technique, employs microorganisms to solubilize metals like copper and gold from low-grade ores, offering a sustainable alternative with reduced ecological impact and lower energy consumption.

Sustainable Tailings Management

Surface mining generates vast volumes of tailings requiring extensive land use and water management, posing environmental risks such as acid mine drainage and heavy metal contamination. Bioleaching offers a sustainable alternative by utilizing microorganisms to extract metals from tailings, reducing hazardous waste and enabling safer, more efficient tailings stabilization and reclamation.

Biogenic Ferric Iron

Surface mining extracts large volumes of ore by removing overburden, whereas bioleaching utilizes microbial activity, specifically biogenic ferric iron produced by bacteria like Acidithiobacillus ferrooxidans, to oxidize and solubilize metal sulfides. The biogenic ferric iron acts as a strong oxidizing agent that enhances metal recovery from low-grade ores with minimal environmental impact compared to traditional surface mining methods.

Selective Biooxidation

Selective biooxidation in bioleaching enhances metal recovery by using specialized microorganisms to target sulfide minerals, offering increased environmental efficiency compared to traditional surface mining. This biotechnological approach reduces the need for extensive excavation and chemical processing, lowering ecological impact while improving extraction specificity.

Surface Mining Automation

Surface mining automation enhances operational efficiency by integrating advanced technologies such as autonomous haul trucks, drones, and real-time data analytics to optimize resource extraction and reduce human intervention. This automation increases safety, lowers operational costs, and improves precision compared to traditional surface mining and bioleaching methods, which rely more heavily on manual labor and slower chemical processes.

Surface mining vs Bioleaching Infographic

industrydif.com

industrydif.com