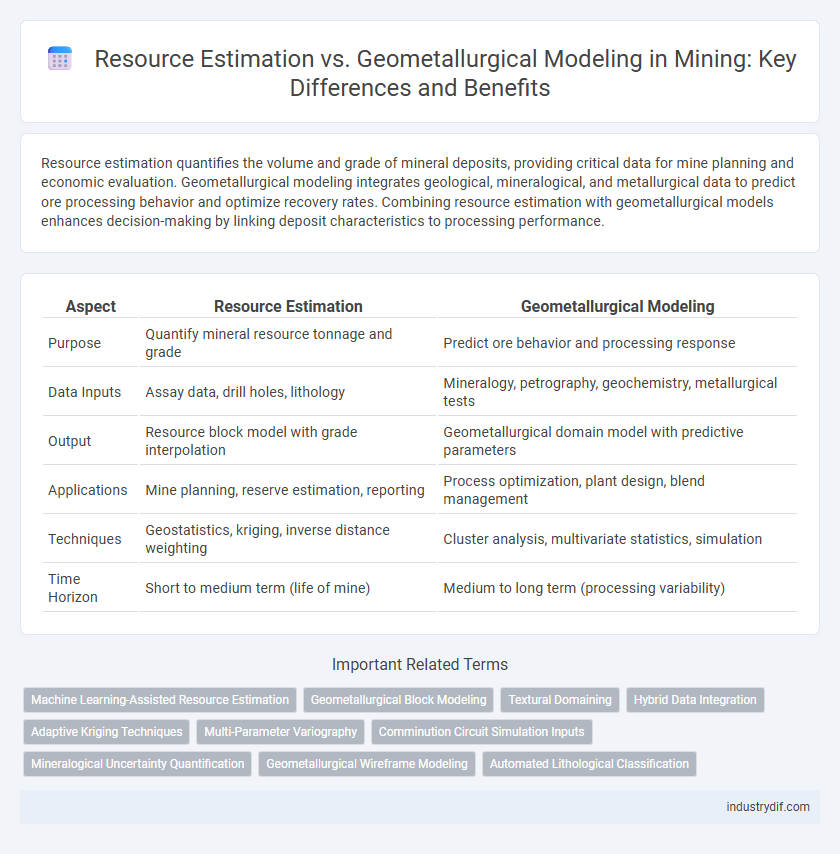

Resource estimation quantifies the volume and grade of mineral deposits, providing critical data for mine planning and economic evaluation. Geometallurgical modeling integrates geological, mineralogical, and metallurgical data to predict ore processing behavior and optimize recovery rates. Combining resource estimation with geometallurgical models enhances decision-making by linking deposit characteristics to processing performance.

Table of Comparison

| Aspect | Resource Estimation | Geometallurgical Modeling |

|---|---|---|

| Purpose | Quantify mineral resource tonnage and grade | Predict ore behavior and processing response |

| Data Inputs | Assay data, drill holes, lithology | Mineralogy, petrography, geochemistry, metallurgical tests |

| Output | Resource block model with grade interpolation | Geometallurgical domain model with predictive parameters |

| Applications | Mine planning, reserve estimation, reporting | Process optimization, plant design, blend management |

| Techniques | Geostatistics, kriging, inverse distance weighting | Cluster analysis, multivariate statistics, simulation |

| Time Horizon | Short to medium term (life of mine) | Medium to long term (processing variability) |

Understanding Resource Estimation in Mining

Resource estimation in mining quantifies the volume and grade of mineral deposits through geological data analysis and statistical modeling, providing a foundational framework for economic evaluation and mine planning. By integrating core sampling, assay results, and geostatistical techniques such as kriging, resource estimation generates reliable estimates of ore tonnage and quality. This process informs key decisions on mine design, feasibility studies, and reserves classification, distinguishing it from geometallurgical modeling, which focuses on predicting ore processing behavior and variability.

Fundamentals of Geometallurgical Modeling

Geometallurgical modeling integrates geological, mineralogical, and metallurgical data to predict ore behavior throughout mining and processing, enhancing resource estimation accuracy. It accounts for variability in ore characteristics such as mineral quality, grain size, and metallurgical properties, enabling optimized blending and processing strategies. This approach improves resource valuation by linking geological models with metallurgical responses, reducing operational risks and increasing economic returns.

Key Differences Between Resource Estimation and Geometallurgical Modeling

Resource estimation quantifies the volume and grade of mineral deposits using geological and assay data to predict potential economic value. Geometallurgical modeling integrates geological, mineralogical, and metallurgical data to characterize ore variability and optimize processing performance. Key differences include resource estimation's focus on deposit size and grade, while geometallurgical modeling emphasizes ore behavior and processing response for improved mine planning.

Data Requirements for Resource Estimation and Geometallurgy

Resource estimation requires extensive drilling data, assay results, and geostatistical information to model ore body geometry and grade distribution accurately. Geometallurgical modeling integrates mineralogical, metallurgical, and geochemical data, emphasizing variability in ore processing characteristics alongside spatial distribution. High-quality, high-density data sets for both approaches ensure reliable predictions of resource quantity and processing performance.

Integrating Geometallurgical Models into Resource Estimates

Integrating geometallurgical models into resource estimates enhances the accuracy of orebody characterization by combining geological, mineralogical, and metallurgical data. This approach allows for improved prediction of variation in ore quality and processing behavior, leading to optimized mine planning and increased economic value. Advanced modeling techniques such as 3D geostatistics and machine learning further refine resource estimates by incorporating complex geometallurgical parameters.

Impact on Mine Planning and Decision Making

Resource estimation quantifies the quantity and quality of mineral deposits, providing critical data for initial project feasibility and reserve reporting. Geometallurgical modeling integrates geological, mineralogical, and metallurgical data to predict ore behavior during processing, enhancing the accuracy of recovery forecasts. Together, these approaches optimize mine planning by aligning extraction strategies with processing capabilities, reducing operational risks and improving economic outcomes.

Advancements in Technology for Enhanced Modeling

Advancements in technology have significantly improved resource estimation and geometallurgical modeling through the integration of high-resolution geospatial data, machine learning algorithms, and real-time sensor inputs. These innovations enable more accurate predictions of ore quality, variability, and spatial distribution, optimizing mine planning and processing strategies. Enhanced modeling techniques reduce uncertainty and operational risk, driving increased efficiency and cost-effectiveness in mineral extraction.

Case Studies: Resource Estimation vs Geometallurgical Outcomes

Case studies reveal distinct advantages of integrating resource estimation with geometallurgical modeling for improved mine planning and operational efficiency. Geometallurgical outcomes provide detailed insights into ore variability and metallurgical behavior, enhancing resource estimation accuracy and optimizing processing strategies. By correlating geological data with metallurgical response, mining projects achieve more reliable forecasts of metal recovery and economic performance.

Challenges in Combining Resource and Geometallurgical Data

Combining resource estimation data with geometallurgical modeling faces significant challenges due to differences in data scale, variability, and uncertainty representation. Resource estimation relies heavily on spatial continuity and grade distribution, while geometallurgical models incorporate complex mineralogical and metallurgical properties that vary non-linearly across deposits. Integrating these datasets requires advanced statistical and geospatial techniques to ensure coherent interpretation and accurate predictive outcomes for mining and processing optimization.

Future Trends in Resource Estimation and Geometallurgical Modeling

Future trends in resource estimation emphasize integrating machine learning algorithms to enhance accuracy and predictive capabilities, leveraging big data from advanced geophysical surveys and drilling. Geometallurgical modeling is evolving with real-time sensor data and AI-driven process simulations to better characterize ore variability and optimize extraction methods. The convergence of these technologies will drive more sustainable and cost-effective mining operations by providing comprehensive, high-resolution resource insights.

Related Important Terms

Machine Learning-Assisted Resource Estimation

Machine learning-assisted resource estimation enhances accuracy by integrating complex geological data patterns commonly overlooked in traditional geometallurgical modeling. Leveraging algorithms such as neural networks and random forests enables predictive analytics that optimize mineral deposit valuation and operational efficiency in mining projects.

Geometallurgical Block Modeling

Geometallurgical block modeling integrates geological, metallurgical, and spatial data to predict ore processing characteristics at a detailed scale, enhancing mine planning accuracy beyond traditional resource estimation that primarily quantifies tonnage and grade. This approach allows for optimized extraction strategies by incorporating variability in mineral processing behavior and reducing operational risks.

Textural Domaining

Resource estimation quantifies mineral quantities and spatial distributions based on geological data, while geometallurgical modeling integrates textural domaining to characterize ore heterogeneity affecting processing behavior. Textural domaining enhances geometallurgical models by segmenting ore bodies into distinct mineralogical and textural units, improving predictions of metallurgical performance and enabling optimized resource extraction strategies.

Hybrid Data Integration

Hybrid data integration combines geological, geochemical, and metallurgical datasets to enhance resource estimation accuracy and operational predictability. This approach improves geometallurgical modeling by incorporating spatial variability and material properties, enabling optimized mine planning and processing strategies.

Adaptive Kriging Techniques

Adaptive Kriging techniques enhance resource estimation accuracy by dynamically updating spatial models with new drilling data, reducing uncertainty in mineral grade predictions and optimizing mine planning. Integrating these techniques within geometallurgical modeling improves the characterization of orebody heterogeneity, enabling more efficient blending strategies and metallurgical recovery forecasts.

Multi-Parameter Variography

Multi-parameter variography enhances resource estimation by quantitatively analyzing spatial correlations among multiple geometallurgical variables, improving prediction accuracy for ore body characteristics. Integrating variogram models with geometallurgical data supports more informed decisions in resource classification and extraction planning.

Comminution Circuit Simulation Inputs

Resource estimation provides crucial geological and grade distribution data essential for defining orebody characteristics, while geometallurgical modeling integrates mineralogical and metallurgical parameters to predict ore behavior during processing. In comminution circuit simulation inputs, combining detailed resource estimates with geometallurgical data enhances the accuracy of throughput, energy consumption, and product size predictions, optimizing plant design and operational efficiency.

Mineralogical Uncertainty Quantification

Resource estimation quantifies ore grade and tonnage using statistical models, ensuring accurate reserve calculations, while geometallurgical modeling integrates mineralogical characterization to predict processing performance and variability. Mineralogical uncertainty quantification enhances these models by providing detailed compositional variance, enabling more reliable predictions of metallurgical behavior and optimizing extraction strategies.

Geometallurgical Wireframe Modeling

Geometallurgical wireframe modeling integrates geological, metallurgical, and mineralogical data to create spatially explicit 3D models that enhance orebody characterization and predict processing performance. This approach provides more precise resource estimation by incorporating variability in mineral properties and recovery factors compared to traditional resource estimation methods.

Automated Lithological Classification

Automated lithological classification enhances resource estimation by providing precise rock type identification, which improves the accuracy of grade distribution and tonnage calculations. Geometallurgical modeling integrates this classification to predict mineral processing behavior, optimizing extraction and recovery strategies through detailed ore characterization.

Resource Estimation vs Geometallurgical Modeling Infographic

industrydif.com

industrydif.com