Smelting involves extracting metals from ores by heating them to high temperatures, often releasing harmful emissions. Green metallurgy emphasizes environmentally friendly techniques, such as bioleaching and recycling, to reduce pollution and energy consumption. Transitioning to green metallurgy supports sustainable mining practices by minimizing environmental impact while maintaining metal production efficiency.

Table of Comparison

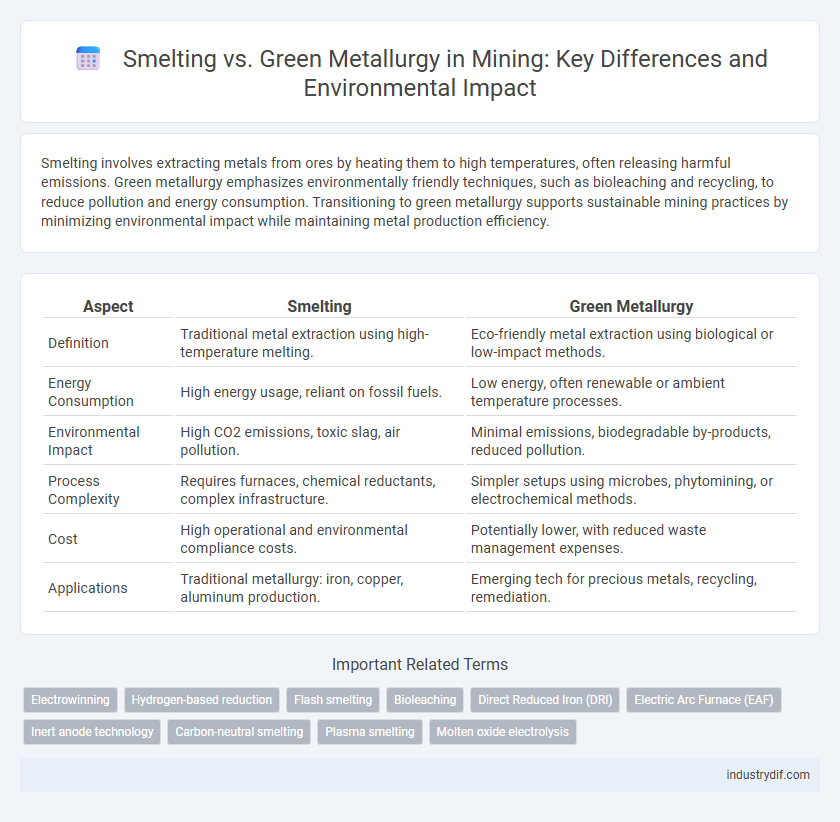

| Aspect | Smelting | Green Metallurgy |

|---|---|---|

| Definition | Traditional metal extraction using high-temperature melting. | Eco-friendly metal extraction using biological or low-impact methods. |

| Energy Consumption | High energy usage, reliant on fossil fuels. | Low energy, often renewable or ambient temperature processes. |

| Environmental Impact | High CO2 emissions, toxic slag, air pollution. | Minimal emissions, biodegradable by-products, reduced pollution. |

| Process Complexity | Requires furnaces, chemical reductants, complex infrastructure. | Simpler setups using microbes, phytomining, or electrochemical methods. |

| Cost | High operational and environmental compliance costs. | Potentially lower, with reduced waste management expenses. |

| Applications | Traditional metallurgy: iron, copper, aluminum production. | Emerging tech for precious metals, recycling, remediation. |

Introduction to Smelting and Green Metallurgy

Smelting is a traditional metallurgical process involving the extraction of metals from ores by heating beyond their melting points to separate impurities. Green metallurgy emphasizes environmentally sustainable techniques, such as bioleaching and solvent extraction, aiming to reduce carbon emissions and hazardous waste. Advances in green metallurgy are transforming mining practices by integrating renewable energy and recyclable materials to minimize ecological impact.

Historical Evolution of Smelting Processes

Smelting processes have evolved from ancient techniques using charcoal and bloomery furnaces to modern methods incorporating electric arc and flash smelting technologies, optimizing metal extraction and energy efficiency. Green metallurgy advances emphasize reducing carbon emissions by integrating renewable energy sources and employing bioleaching to minimize environmental impact. Historical evolution reflects a shift from high-pollution, energy-intensive smelting toward sustainable, eco-friendly practices aligned with global climate goals.

Principles of Traditional Smelting

Traditional smelting relies on high-temperature chemical reduction processes to extract metals from ore, typically involving the use of carbon-based fuels such as coke or charcoal to reduce metal oxides into pure metal. This method generates significant greenhouse gas emissions and produces hazardous byproducts like slag and sulfur dioxide, raising environmental concerns. In contrast, green metallurgy prioritizes sustainable techniques, minimizing emissions and waste by employing innovative technologies such as bioleaching, electrochemical methods, and closed-loop recycling systems.

Environmental Impact of Conventional Smelting

Conventional smelting releases significant amounts of sulfur dioxide, heavy metals, and particulate matter, contributing to air pollution, acid rain, and health hazards. The energy-intensive nature of smelting also results in high greenhouse gas emissions, exacerbating climate change. In contrast, green metallurgy aims to minimize these environmental impacts through cleaner technologies and reduced waste generation.

Introduction to Green Metallurgy

Green metallurgy emphasizes sustainable metal extraction techniques that minimize environmental impact by reducing energy consumption and toxic emissions. Unlike traditional smelting, which relies heavily on high-temperature processes and fossil fuels, green metallurgy employs alternative methods such as bioleaching, hydrogen-based reduction, and electrochemical refining. These innovative approaches contribute to lower carbon footprints and promote resource efficiency in mining operations.

Key Technologies in Green Metallurgy

Green metallurgy emphasizes sustainable technologies such as bioleaching, which uses microorganisms to extract metals from ores, reducing energy consumption and harmful emissions compared to traditional smelting. Hydrometallurgical methods employ aqueous chemistry for metal recovery, offering lower environmental impact and higher selectivity. Advanced techniques like electrochemical processing and solvent extraction further optimize metal purification while minimizing waste and pollution.

Comparative Analysis: Smelting vs Green Metallurgy

Smelting, a traditional high-temperature process, involves extracting metals from ore by applying intense heat and chemical reducing agents, often emitting significant greenhouse gases and pollutants. Green metallurgy emphasizes eco-friendly techniques such as bioleaching, solvent extraction, and electrochemical processes that reduce energy consumption and minimize environmental impact. Comparative analysis highlights green metallurgy's advantages in sustainability and regulatory compliance, although smelting remains dominant for high-yield industrial applications due to its efficiency and cost-effectiveness.

Economic Considerations and Feasibility

Smelting requires significant energy input and high operational costs due to fossil fuel dependence, whereas green metallurgy employs renewable energy and eco-friendly processes that reduce long-term expenses and regulatory liabilities. Investment in green metallurgy shows rising feasibility as carbon pricing and stricter environmental regulations increase the economic burden on traditional smelting. The transition to green metallurgy can improve profitability by lowering emissions-related penalties and benefiting from government incentives supporting sustainable mining technologies.

Regulatory and Sustainability Trends in Metallurgy

Regulatory trends in metallurgy are increasingly favoring green metallurgy due to stricter environmental laws targeting emissions and waste from traditional smelting processes. Sustainability frameworks emphasize energy efficiency, reduced carbon footprint, and recycling in metal extraction, making green metallurgy a strategic choice for compliance and social responsibility. Advances in alternative technologies such as hydrometallurgy and bioleaching align with global sustainability goals and regulatory incentives promoting cleaner metal production methods.

Future Outlook for Metallurgical Innovations

Smelting, a traditional metallurgical process reliant on high-temperature reduction of ores, faces challenges due to its significant carbon emissions and energy consumption. Green metallurgy emphasizes sustainable techniques, including bioleaching, electrochemical methods, and low-temperature processing, aiming to minimize environmental impact while enhancing resource efficiency. The future outlook highlights increased integration of renewable energy-powered smelting technologies and advanced recycling methods, driving metallurgical innovations toward decarbonization and circular economy models.

Related Important Terms

Electrowinning

Smelting, a traditional high-temperature process, releases significant greenhouse gases, whereas green metallurgy techniques like electrowinning offer energy-efficient, eco-friendly metal extraction by using electric currents to deposit metals directly from solutions. Electrowinning reduces environmental impact through lower emissions and waste generation, making it a sustainable alternative in modern mining operations.

Hydrogen-based reduction

Hydrogen-based reduction in green metallurgy offers a sustainable alternative to traditional smelting by significantly lowering carbon emissions and utilizing green hydrogen as a reducing agent. This innovative process enhances ore beneficiation efficiency and aligns with global decarbonization targets in the mining industry.

Flash smelting

Flash smelting, a high-efficiency pyrometallurgical process, reduces energy consumption and sulfur dioxide emissions compared to traditional smelting techniques, aligning more closely with green metallurgy principles. This method rapidly oxidizes sulfide ores using oxygen-enriched air, enhancing metal recovery rates while minimizing environmental impact and operational costs.

Bioleaching

Bioleaching, a key process in green metallurgy, utilizes microorganisms to extract metals from ores, significantly reducing the environmental impact compared to traditional smelting, which relies on high-temperature treatments and generates toxic emissions. This biologically driven technique not only lowers greenhouse gas emissions but also offers a sustainable alternative for processing low-grade and complex ores often unsuitable for conventional smelting methods.

Direct Reduced Iron (DRI)

Direct Reduced Iron (DRI) production through green metallurgy uses natural gas or hydrogen instead of coal, significantly reducing carbon emissions compared to traditional smelting. This eco-friendly approach enhances energy efficiency and supports sustainable mining by minimizing environmental impact in steelmaking processes.

Electric Arc Furnace (EAF)

Electric Arc Furnace (EAF) technology in smelting leverages high-temperature electric arcs to melt scrap steel or direct reduced iron, offering efficient metal recovery with reduced greenhouse gas emissions compared to traditional blast furnaces. Green metallurgy emphasizes EAF's role in sustainable mining by integrating renewable energy sources and recycling materials, significantly decreasing carbon footprints and conserving natural resources.

Inert anode technology

Inert anode technology revolutionizes smelting by replacing traditional carbon anodes with stable, non-consumable materials, drastically reducing CO2 emissions and energy consumption in metal extraction. This advancement underpins green metallurgy principles by enabling cleaner, more sustainable aluminum production with minimal environmental impact.

Carbon-neutral smelting

Carbon-neutral smelting integrates renewable energy sources and carbon capture technologies to significantly reduce greenhouse gas emissions compared to traditional smelting methods. Green metallurgy emphasizes sustainable practices by utilizing low-carbon materials and closed-loop processes that minimize environmental impact while maintaining metal purity and production efficiency.

Plasma smelting

Plasma smelting offers a sustainable alternative to traditional smelting by using high-temperature plasma torches to efficiently extract metals while reducing greenhouse gas emissions and toxic waste. Green metallurgy leverages plasma smelting technology to enhance energy efficiency and minimize environmental impact in metal production processes.

Molten oxide electrolysis

Molten oxide electrolysis (MOE) revolutionizes smelting by eliminating carbon emissions traditionally produced during metal extraction processes, supporting green metallurgy's eco-friendly goals. This technology directly electrolyzes metal oxides at high temperatures, reducing reliance on carbon-intensive methods and advancing sustainable mining practices.

Smelting vs Green metallurgy Infographic

industrydif.com

industrydif.com