Orebody modeling provides a detailed, static representation of mineral deposits based on geological data, enabling accurate estimation of ore grade and volume. Digital twins offer dynamic, real-time simulations of mining operations by integrating sensor data, process analytics, and predictive models to optimize production and maintenance. Combining orebody modeling with digital twin technology enhances decision-making, reduces operational risks, and maximizes resource extraction efficiency.

Table of Comparison

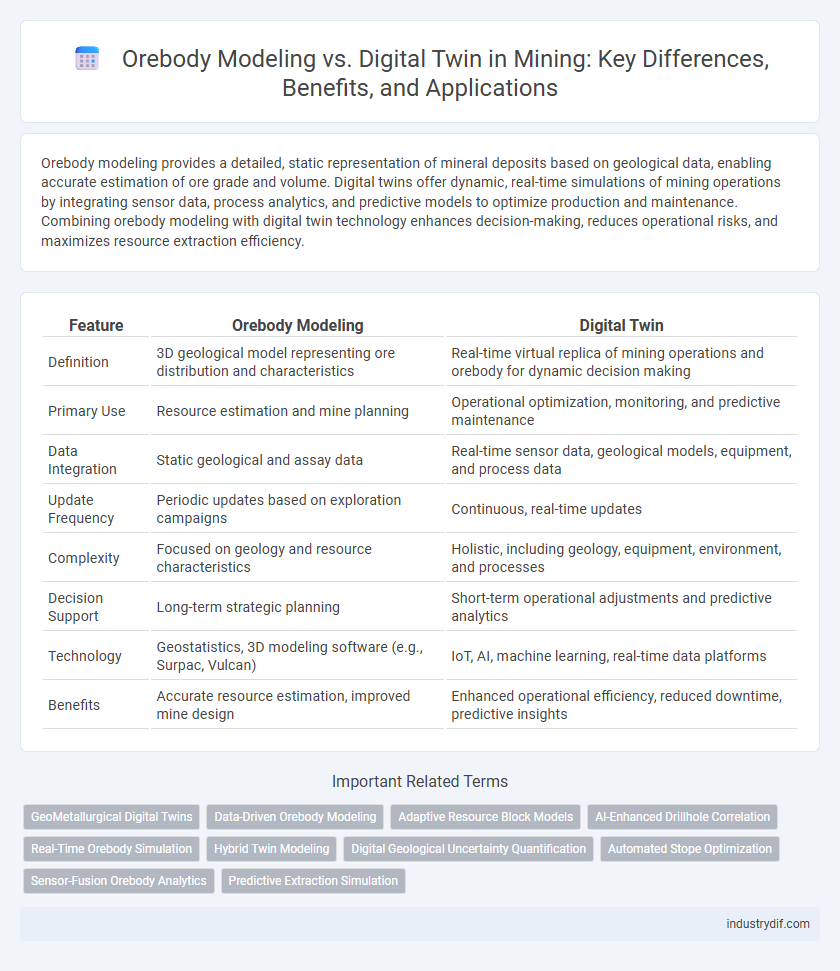

| Feature | Orebody Modeling | Digital Twin |

|---|---|---|

| Definition | 3D geological model representing ore distribution and characteristics | Real-time virtual replica of mining operations and orebody for dynamic decision making |

| Primary Use | Resource estimation and mine planning | Operational optimization, monitoring, and predictive maintenance |

| Data Integration | Static geological and assay data | Real-time sensor data, geological models, equipment, and process data |

| Update Frequency | Periodic updates based on exploration campaigns | Continuous, real-time updates |

| Complexity | Focused on geology and resource characteristics | Holistic, including geology, equipment, environment, and processes |

| Decision Support | Long-term strategic planning | Short-term operational adjustments and predictive analytics |

| Technology | Geostatistics, 3D modeling software (e.g., Surpac, Vulcan) | IoT, AI, machine learning, real-time data platforms |

| Benefits | Accurate resource estimation, improved mine design | Enhanced operational efficiency, reduced downtime, predictive insights |

Definition of Orebody Modeling in Mining

Orebody modeling in mining involves the creation of a three-dimensional representation of mineral deposits, integrating geological, geophysical, and geochemical data to estimate the quantity and quality of ore. This process uses techniques such as kriging and geostatistics to predict ore distribution and support mine planning. Orebody models serve as a foundation for decision-making by providing detailed insights into resource estimation and spatial variability.

Understanding Digital Twin Technology in Mining

Digital twin technology in mining provides a dynamic, real-time digital replica of physical orebody conditions, enabling continuous monitoring and predictive analysis beyond traditional static orebody modeling. Unlike orebody models which primarily focus on geological data interpretation, digital twins integrate sensor data, operational parameters, and environmental factors to optimize mine planning and enhance decision-making. This holistic approach reduces operational risks and improves resource extraction efficiency by simulating actual mine behavior and performance under various scenarios.

Key Differences Between Orebody Modeling and Digital Twin

Orebody modeling primarily focuses on creating a geological representation of mineral deposits using drilling and sampling data to estimate ore grade and volume, crucial for mine planning. A digital twin integrates real-time operational data and advanced analytics to simulate, predict, and optimize mining processes throughout the asset lifecycle. Unlike static orebody models, digital twins provide dynamic, continuous updates for enhanced decision-making and risk management in mining operations.

Integration of Digital Twin and Orebody Modeling

Integration of digital twin technology with orebody modeling enhances real-time data synchronization and predictive analytics, enabling more precise ore grade estimations and efficient mine planning. Digital twins provide dynamic simulations of the orebody's physical and chemical properties, improving decision-making by continuously updating models with sensor data from mining operations. This synergy leads to optimized resource extraction, reduced operational risks, and increased overall mine productivity.

Impact on Operational Efficiency

Orebody modeling enhances operational efficiency by providing detailed geological data that optimizes mine planning and resource estimation, reducing extraction errors and waste. Digital twins simulate real-time mine operations, enabling dynamic decision-making and predictive maintenance that minimize downtime and boost productivity. Integrating both technologies transforms mining workflows, resulting in significant cost savings and improved resource utilization.

Data Sources and Quality: Orebody Models vs Digital Twins

Orebody modeling relies heavily on historical geological data, drill hole assays, and sampling records to create static representations of mineral deposits, often limited by data gaps and resolution. Digital twins integrate real-time sensor data, geospatial analytics, and operational metrics, enabling dynamic, high-fidelity simulations that reflect current mine conditions. Data quality in digital twins is enhanced through continuous validation and updates from multiple sources, providing greater accuracy and predictive capabilities compared to traditional orebody models.

Real-Time Monitoring Capabilities

Orebody modeling provides static geological representations based on historical data, while digital twins integrate real-time monitoring capabilities to continuously update orebody conditions. Digital twins leverage sensor data and advanced analytics to enable dynamic decision-making, optimizing extraction processes and minimizing operational risks. The real-time insights from digital twins enhance predictive maintenance and resource allocation compared to conventional orebody models.

Applications in Mine Planning and Optimization

Orebody modeling provides a detailed geological representation critical for resource estimation and block modeling, enabling accurate volume and grade predictions essential for mine planning. Digital twins integrate real-time data from mining operations with orebody models to simulate process flow, equipment performance, and environmental conditions, enhancing decision-making for production scheduling and equipment maintenance. Combining orebody models with digital twin technology optimizes resource extraction by improving operational efficiency, reducing costs, and enabling adaptive mine planning under dynamic conditions.

Challenges and Limitations

Orebody modeling faces challenges such as limited spatial data, geological uncertainty, and difficulties in accurately representing mineral distributions, impacting resource estimation and mine planning. Digital twins encounter limitations related to real-time data integration, high computational demands, and managing complex interactions between geological, operational, and environmental factors. Both methodologies require overcoming data quality issues, interoperability barriers, and the need for continuous updates to ensure reliable decision-making in mining operations.

Future Trends in Mining Technology

Orebody modeling remains essential for accurately defining mineral deposit geometry, while digital twin technology offers dynamic real-time simulation of mining operations. Integration of AI, machine learning, and IoT sensors drives predictive analytics, enabling proactive decision-making and optimization of extraction processes. Future trends emphasize seamless data fusion between orebody models and digital twins to enhance efficiency, safety, and environmental sustainability in mining projects.

Related Important Terms

GeoMetallurgical Digital Twins

GeoMetallurgical Digital Twins integrate orebody modeling with real-time data to create dynamic simulations that enhance predictive accuracy in mineral processing and mine planning. These digital twins enable continuous optimization of extraction strategies by combining geological, metallurgical, and operational data into a unified, interactive model.

Data-Driven Orebody Modeling

Data-driven orebody modeling integrates advanced geostatistical techniques and machine learning algorithms to create highly detailed and dynamic representations of mineral deposits, enhancing resource estimation accuracy. Unlike traditional digital twins that simulate physical processes, data-driven models leverage real-time geological and operational data for continuous updates, enabling more informed decision-making in mining exploration and production.

Adaptive Resource Block Models

Adaptive Resource Block Models enable dynamic updates of orebody characteristics by integrating real-time data streams, enhancing precision in resource estimation and mine planning. Unlike traditional Digital Twins which simulate operational processes, these models offer granular control over geological variability, improving responsiveness to spatial and temporal changes in the orebody.

AI-Enhanced Drillhole Correlation

AI-enhanced drillhole correlation improves orebody modeling by accurately interpreting geological data, enabling precise resource estimation and reducing uncertainty in mineral deposit characterization. Digital twins integrate this AI-driven insight with real-time operational data, optimizing mine planning and enhancing decision-making throughout the mining lifecycle.

Real-Time Orebody Simulation

Real-time orebody simulation integrates dynamic data from sensors and geological surveys to create highly accurate orebody models, enhancing predictive accuracy and operational decision-making. Digital twins extend this capability by providing continuous virtual replicas of mining environments, enabling real-time monitoring, optimization, and adaptive control of ore extraction processes.

Hybrid Twin Modeling

Hybrid twin modeling integrates orebody modeling and digital twin technologies to enhance mine planning accuracy and operational efficiency by combining geological data with real-time sensor inputs. This approach enables dynamic simulation of orebody conditions and equipment performance, improving decision-making through continuous updates and predictive analytics.

Digital Geological Uncertainty Quantification

Digital Geological Uncertainty Quantification in orebody modeling enhances predictive accuracy by integrating stochastic simulations and spatial statistics to capture subsurface variability. Digital twins extend this by creating dynamic, real-time models that continuously update geological uncertainty with new data inputs, optimizing mine planning and risk management.

Automated Stope Optimization

Automated Stope Optimization leverages advanced algorithms within orebody modeling to accurately define ore boundaries and optimize extraction sequences, enhancing resource recovery and minimizing dilution. Digital twins integrate real-time data from mining operations, enabling dynamic adjustments to stope designs and improving decision-making in automated stope optimization processes.

Sensor-Fusion Orebody Analytics

Sensor-fusion orebody analytics integrates multisensor data to enhance orebody modeling accuracy by providing real-time, high-resolution geological and geophysical information. Digital twins build upon these analytics by creating dynamic, virtual replicas of mining operations, enabling predictive optimization and adaptive decision-making throughout the ore extraction process.

Predictive Extraction Simulation

Orebody modeling captures geological variations and spatial distributions essential for resource estimation, whereas digital twin technology integrates real-time sensor data to enable predictive extraction simulation, optimizing mining operations and minimizing downtime. Predictive extraction simulation leverages digital twins to forecast equipment performance and material behavior, enhancing decision-making and increasing extraction efficiency.

Orebody modeling vs Digital twin Infographic

industrydif.com

industrydif.com