Truck and Shovel Mining relies on manual operation of heavy equipment, which can lead to slower cycle times and increased labor costs. Autonomous Haulage Systems (AHS) use driverless trucks guided by advanced sensors and GPS technology, improving safety and operational efficiency. The integration of AHS reduces human error, maximizes equipment utilization, and lowers overall mining expenses.

Table of Comparison

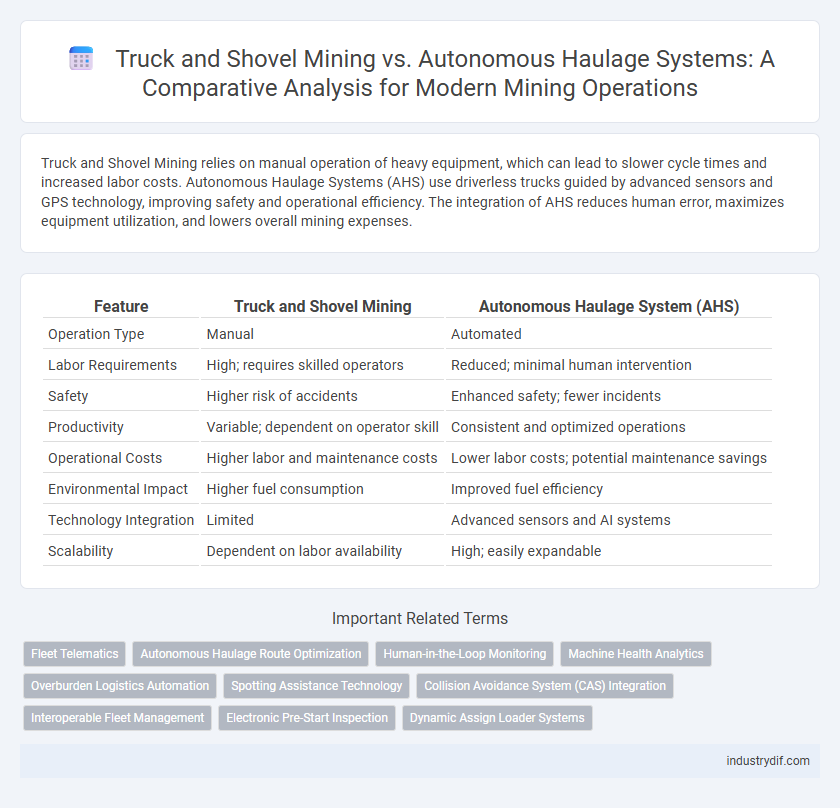

| Feature | Truck and Shovel Mining | Autonomous Haulage System (AHS) |

|---|---|---|

| Operation Type | Manual | Automated |

| Labor Requirements | High; requires skilled operators | Reduced; minimal human intervention |

| Safety | Higher risk of accidents | Enhanced safety; fewer incidents |

| Productivity | Variable; dependent on operator skill | Consistent and optimized operations |

| Operational Costs | Higher labor and maintenance costs | Lower labor costs; potential maintenance savings |

| Environmental Impact | Higher fuel consumption | Improved fuel efficiency |

| Technology Integration | Limited | Advanced sensors and AI systems |

| Scalability | Dependent on labor availability | High; easily expandable |

Overview of Truck and Shovel Mining Operations

Truck and Shovel Mining operations rely on a fleet of large off-highway trucks and hydraulic or cable shovels to excavate and transport mined material, heavily depending on skilled operators and real-time coordination. These operations are characterized by flexible deployment across various terrain types, enabling efficient ore extraction and waste removal in surface mining environments. Despite advances in automation, traditional truck and shovel methods remain vital for their adaptability and proven reliability in diverse mining conditions.

Introduction to Autonomous Haulage Systems (AHS)

Autonomous Haulage Systems (AHS) revolutionize traditional truck and shovel mining by integrating driverless trucks equipped with advanced GPS, sensors, and AI technology, enhancing operational efficiency and safety. AHS optimizes fleet management through real-time data analytics, reducing human error and lowering operational costs while maintaining consistent haul cycles. This system enables seamless coordination between autonomous trucks and shovels, maximizing productivity in large-scale mining operations.

Key Components of Conventional Truck and Shovel Mining

Conventional truck and shovel mining relies on key components such as hydraulic excavators, articulated haul trucks, and operator control cabins to manually manage material extraction and transportation. These systems depend on skilled operators for real-time decision-making, ensuring efficiency in loading, hauling, and dumping cycles. Maintenance facilities and fuel supply infrastructure are critical to support continuous operation and mitigate downtime in truck and shovel fleets.

Core Technologies in Autonomous Haulage Systems

Autonomous Haulage Systems (AHS) utilize advanced core technologies including GPS for precise vehicle positioning, LiDAR and radar sensors for obstacle detection and navigation, and AI-driven software for real-time decision-making and fleet management. These technologies enable optimized route planning, enhanced safety through collision avoidance, and increased operational efficiency compared to traditional Truck and Shovel Mining methods. Integration of machine learning algorithms further improves predictive maintenance and reduces downtime in large-scale mining operations.

Productivity Comparison: Manual vs Autonomous Hauling

Manual truck and shovel mining typically results in lower productivity due to operator fatigue and variability in driving performance, causing delays and inefficient material transport. Autonomous Haulage Systems (AHS) enhance productivity by enabling continuous, precise, and coordinated haulage operations, reducing cycle times and increasing payload efficiency. Studies show AHS can improve productivity by 10-20% compared to manual hauling, significantly optimizing mining operations and lowering operational costs.

Safety Improvements with Autonomous Haulage

Autonomous Haulage Systems (AHS) significantly enhance safety in mining operations by reducing human exposure to hazardous conditions typically encountered in truck and shovel mining. These systems utilize advanced sensors, GPS, and real-time data analytics to avoid collisions, monitor equipment health, and maintain optimal traffic flow, thereby minimizing accident risks. The elimination of driver fatigue and human error further contributes to a safer mining environment, supporting regulatory compliance and reducing downtime caused by incidents.

Workforce Implications: Skills and Job Roles

Truck and Shovel Mining requires skilled operators proficient in maneuvering heavy machinery and maintaining equipment, emphasizing hands-on expertise and traditional labor roles. Autonomous Haulage Systems (AHS) significantly shift workforce demands toward advanced technical skills in remote operation, systems monitoring, and data analysis, reducing the need for on-site operators. This transition fosters new job roles in robotics maintenance, IT support, and systems engineering, while potentially decreasing the number of truck drivers and heavy machinery operators.

Environmental Impact and Fuel Efficiency

Truck and Shovel Mining typically involves diesel-powered haul trucks, leading to higher greenhouse gas emissions and greater fuel consumption compared to Autonomous Haulage Systems (AHS). AHS utilizes electric or hybrid vehicles with optimized routes and operational efficiency, significantly reducing carbon footprint and fuel use. Implementing autonomous haulage enhances sustainability by lowering NOx emissions and improving energy efficiency across mining operations.

Capital and Operational Cost Analysis

Truck and Shovel Mining typically incurs higher capital expenses due to procurement of conventional haul trucks and shovels, alongside substantial operational costs related to manual labor and maintenance. Autonomous Haulage Systems (AHS) demonstrate cost efficiency by reducing labor expenses and enhancing fuel consumption through optimized route management, although initial capital investment for sensor technology and system integration remains significant. Over the long term, AHS offers reduced total cost of ownership by minimizing downtime and increasing productivity compared to traditional Truck and Shovel operations.

Future Trends in Mining Haulage Technologies

Truck and Shovel Mining remains a foundational method in surface mining with proven efficiency and flexibility in varying terrain conditions. Autonomous Haulage Systems (AHS) represent the forefront of mining haulage technologies, delivering enhanced safety, reduced operational costs, and improved productivity through automation and real-time data analytics. Future trends indicate increased integration of AI, IoT sensors, and predictive maintenance in AHS to optimize fleet utilization and minimize environmental impact in large-scale mining operations.

Related Important Terms

Fleet Telematics

Fleet telematics in Truck and Shovel Mining integrates GPS tracking, fuel sensors, and real-time vehicle diagnostics to optimize equipment utilization and reduce downtime. Autonomous Haulage Systems leverage advanced telematics combined with AI-driven route optimization and predictive maintenance, enhancing operational efficiency and safety by minimizing human error.

Autonomous Haulage Route Optimization

Autonomous Haulage Systems (AHS) enhance mining efficiency by using advanced algorithms and real-time data to optimize haul routes, reducing fuel consumption and cycle times compared to traditional Truck and Shovel Mining operations. Route optimization in AHS leverages GPS, machine learning, and sensor inputs to dynamically adjust paths for improved safety, increased payload delivery, and lower operational costs.

Human-in-the-Loop Monitoring

Human-in-the-Loop monitoring in Truck and Shovel Mining integrates operator oversight to enhance safety and decision-making, blending manual control with automated assistance for real-time issue resolution. Autonomous Haulage Systems rely on advanced AI and sensor networks to continuously monitor haulage operations, reducing human error but still requiring human intervention for system anomalies and strategic adjustments.

Machine Health Analytics

Machine health analytics in Truck and Shovel Mining utilizes real-time sensor data to monitor equipment performance and predict maintenance needs, reducing downtime and operational costs. Autonomous Haulage Systems integrate advanced machine learning algorithms and IoT connectivity to enhance predictive maintenance accuracy, optimize fleet utilization, and extend machinery lifespan through continuous health monitoring.

Overburden Logistics Automation

Truck and Shovel Mining relies on manual operation and scheduled dispatching, resulting in inefficiencies in overburden logistics and increased downtime. Autonomous Haulage System (AHS) optimizes overburden removal by integrating automated trucks with real-time data analytics, enhancing cycle times and reducing operational costs through precise route planning and continuous vehicle coordination.

Spotting Assistance Technology

Spotting Assistance Technology in Truck and Shovel Mining enhances operator precision by providing real-time sensor data and visual guidance, reducing equipment collisions and improving loading efficiency. Autonomous Haulage Systems integrate advanced algorithms with spotting assistance to enable driverless trucks to autonomously position themselves accurately for shovel loading, boosting productivity and safety in mining operations.

Collision Avoidance System (CAS) Integration

Truck and Shovel Mining relies heavily on manual operation with limited real-time collision avoidance technology, resulting in higher risk of human error and equipment damage. In contrast, Autonomous Haulage Systems integrate advanced Collision Avoidance Systems (CAS) using LiDAR, radar, and AI algorithms to enhance safety by autonomously detecting and preventing collisions, optimizing mining efficiency and reducing downtime.

Interoperable Fleet Management

Interoperable Fleet Management enables seamless coordination between Truck and Shovel Mining and Autonomous Haulage Systems, optimizing operational efficiency and reducing downtime. Integrating both systems allows real-time data exchange, enhances resource allocation, and supports synchronized dispatching to maximize overall productivity in mining operations.

Electronic Pre-Start Inspection

Truck and Shovel Mining relies on manual Electronic Pre-Start Inspections to ensure equipment safety and operational readiness, often requiring operator presence and documentation. Autonomous Haulage Systems enhance this process with automated Electronic Pre-Start Inspections using onboard sensors and AI, reducing human error and improving efficiency in mining operations.

Dynamic Assign Loader Systems

Dynamic Assign Loader Systems enhance efficiency in Truck and Shovel Mining by optimizing loader-truck interactions through real-time data analysis and task allocation. Autonomous Haulage Systems integrate these dynamic assignments to improve fleet coordination, reduce cycle times, and increase overall productivity in mining operations.

Truck and Shovel Mining vs Autonomous Haulage System Infographic

industrydif.com

industrydif.com