Blasting uses controlled explosives to fracture rock rapidly, enabling efficient extraction but generating vibrations and requiring strict safety measures. Non-explosive rock breaking employs chemical agents or mechanical methods to gradually crack rock, reducing noise, dust, and environmental impact while enhancing operational safety. Selecting between blasting and non-explosive techniques depends on site conditions, environmental constraints, and project objectives.

Table of Comparison

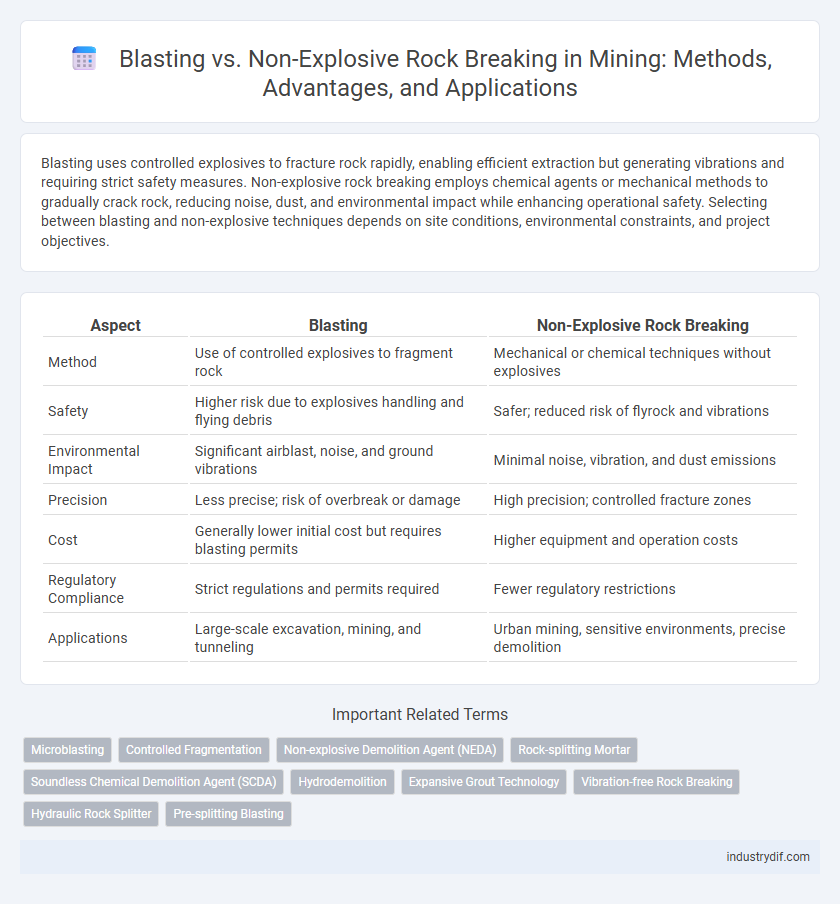

| Aspect | Blasting | Non-Explosive Rock Breaking |

|---|---|---|

| Method | Use of controlled explosives to fragment rock | Mechanical or chemical techniques without explosives |

| Safety | Higher risk due to explosives handling and flying debris | Safer; reduced risk of flyrock and vibrations |

| Environmental Impact | Significant airblast, noise, and ground vibrations | Minimal noise, vibration, and dust emissions |

| Precision | Less precise; risk of overbreak or damage | High precision; controlled fracture zones |

| Cost | Generally lower initial cost but requires blasting permits | Higher equipment and operation costs |

| Regulatory Compliance | Strict regulations and permits required | Fewer regulatory restrictions |

| Applications | Large-scale excavation, mining, and tunneling | Urban mining, sensitive environments, precise demolition |

Introduction to Rock Breaking Methods in Mining

Rock breaking methods in mining are critical for efficient extraction and safety management. Blasting uses controlled explosions to fracture rock rapidly, offering high productivity in hard rock environments, while non-explosive rock breaking employs hydraulic or mechanical techniques for precision and reduced vibration. Selecting between blasting and non-explosive methods depends on geological conditions, environmental regulations, and operational requirements.

Overview of Blasting Techniques

Blasting techniques in mining involve controlled use of explosives to fracture rock efficiently, enabling large-scale material displacement with precise timing and charge placement. Common methods include conventional blasting, controlled blasting for vibration reduction, and electronic detonation systems that improve safety and fragmentation uniformity. These techniques optimize extraction rates, reduce operational costs, and minimize environmental impact compared to non-explosive rock breaking methods.

Principles of Non-Explosive Rock Breaking

Non-explosive rock breaking utilizes controlled chemical agents that expand gradually to fracture rock without vibrations or noise associated with blasting. The principle relies on the slow hydration and crystallization of expansive mortar within drilled holes, exerting uniform pressure to create fractures along predetermined lines. This method enhances safety in sensitive environments, minimizes environmental impact, and allows precise rock fragmentation where explosives are restricted.

Safety Considerations: Blasting vs Non-Explosive Methods

Blasting in mining involves the use of explosives, posing significant safety risks such as flyrock, air blasts, and ground vibrations, necessitating strict regulatory compliance and extensive safety protocols. Non-explosive rock breaking methods minimize these hazards by eliminating explosive use, reducing noise, dust, and ground vibrations, which enhances worker safety and environmental protection. Selecting between blasting and non-explosive techniques depends on site-specific safety requirements, geological conditions, and proximity to populated areas.

Environmental Impact Comparison

Blasting in mining generates significant air and noise pollution, releases dust and vibrations harmful to nearby ecosystems, and produces fly rock that poses safety risks. Non-explosive rock breaking methods reduce environmental impact by minimizing dust, noise, and ground vibrations, leading to a safer and more controlled excavation process. These techniques also lower the risk of water contamination and habitat disruption, promoting sustainable mining practices.

Cost Analysis: Explosive vs Non-Explosive Solutions

Explosive blasting in mining offers rapid rock fragmentation and lower upfront costs but involves higher safety risks, regulatory expenses, and environmental impacts that can increase overall project costs. Non-explosive rock breaking solutions, such as hydraulic splitters and expanding grout, incur higher initial equipment and material expenses but reduce safety risks, minimize vibration damage, and lower long-term operational and compliance costs. Cost analysis must weigh immediate blasting efficiency against the sustainable benefits and potential savings of non-explosive techniques for optimal mining project economics.

Efficiency and Productivity Metrics

Blasting achieves higher fragmentation efficiency and faster cycle times by breaking large volumes of rock simultaneously, resulting in improved productivity metrics such as reduced drilling and loading times. Non-explosive rock breaking ensures greater precision and safety, minimizing environmental impacts like vibration and flyrock but typically exhibits lower throughput compared to traditional blasting. Mining operations balance these methods by evaluating site-specific conditions, cost factors, and desired output rates to optimize overall extraction efficiency.

Regulatory and Compliance Factors

Blasting in mining operations is strictly regulated by government agencies such as MSHA and OSHA, requiring permits, safety protocols, and strict adherence to environmental standards to control air blast, ground vibration, and fly rock hazards. Non-explosive rock breaking methods, while generally subject to fewer regulatory restrictions, must still comply with environmental impact assessments and local noise ordinances to ensure workplace safety and minimal environmental disturbance. Compliance with these regulations impacts operational planning, cost management, and community relations within mining projects.

Applications and Suitability for Different Rock Types

Blasting is highly effective for hard, massive rock formations such as granite and basalt, delivering rapid fragmentation and high energy efficiency, making it ideal for large-scale mining and quarrying operations. Non-explosive rock breaking methods, including hydraulic splitting and expansive grouts, are more suitable for controlled demolition of sensitive structures and softer rock types like limestone or shale, minimizing vibrations and environmental impact. Selection between blasting and non-explosive techniques depends on factors such as rock hardness, environmental constraints, and project scale, ensuring optimal fragmentation and operational safety.

Future Trends in Rock Fragmentation Technologies

Future trends in rock fragmentation technologies emphasize the shift from traditional blasting methods toward non-explosive rock breaking techniques to enhance safety and reduce environmental impact. Innovations in hydraulic fracturing, mechanical splitting, and chemical expansion agents are gaining prominence for their precision and ability to minimize vibration and dust generation. The integration of automation and real-time monitoring systems further optimizes fragmentation efficiency, supporting sustainable mining operations.

Related Important Terms

Microblasting

Microblasting, a precise and controlled rock breaking technique, uses micro-detonations to minimize vibrations, enhance safety, and reduce environmental impact compared to traditional blasting methods. This non-explosive approach offers improved fragmentation control and is ideal for sensitive mining operations requiring minimal disturbance to surrounding structures.

Controlled Fragmentation

Controlled fragmentation in blasting ensures precise rock breakage by using carefully calculated explosive charges to optimize fragment size and minimize overbreak, enhancing safety and operational efficiency in mining. Non-explosive rock breaking techniques achieve fragmentation through mechanical or chemical methods, offering reduced vibration and noise but often requiring longer cycle times and higher energy consumption.

Non-explosive Demolition Agent (NEDA)

Non-explosive Demolition Agent (NEDA) offers a safer, vibration-free alternative to traditional blasting in mining operations, effectively fracturing rock without the risks associated with explosives. Its controlled expansion creates precise rock breakup, reducing environmental impact and enhancing worker safety while maintaining operational efficiency.

Rock-splitting Mortar

Rock-splitting mortar offers a controlled, vibration-free alternative to traditional blasting methods, enabling precise fracturing of rock in mining operations where safety and environmental concerns are paramount. This non-explosive technique enhances operational efficiency by reducing noise, dust, and fly rock hazards while maintaining effective rock breakage in confined spaces.

Soundless Chemical Demolition Agent (SCDA)

Soundless Chemical Demolition Agents (SCDA) offer a non-explosive alternative to traditional blasting by chemically expanding rock fractures without generating noise or vibrations, improving safety and minimizing environmental impact. SCDA's precision in controlled rock breaking reduces the risk of flyrock and ground disturbances, making it ideal for sensitive mining operations and urban mining sites.

Hydrodemolition

Hydrodemolition uses high-pressure water jets to fracture rock, offering precise, controlled removal with minimal vibration and reduced environmental impact compared to blasting techniques. This method enhances safety and minimizes damage to surrounding rock structures, making it an efficient alternative for selective rock breaking in sensitive mining operations.

Expansive Grout Technology

Expansive Grout Technology provides a controlled, vibration-free alternative to traditional blasting by using chemical expansion to fracture rock, minimizing environmental impact and enhancing safety in mining operations. This non-explosive rock breaking method reduces noise, flyrock, and dust generation, improving operational efficiency and compliance with environmental regulations.

Vibration-free Rock Breaking

Vibration-free rock breaking methods, such as hydraulic splitting and expansive chemical agents, offer precise control in mining operations by minimizing ground vibrations and reducing damage to surrounding structures. These non-explosive techniques enhance safety and stability in sensitive environments where traditional blasting could cause hazardous seismic impacts.

Hydraulic Rock Splitter

Hydraulic Rock Splitters offer a controlled, vibration-free alternative to traditional blasting methods, minimizing environmental impact and enhancing worker safety in mining operations. This non-explosive rock breaking technique enables precise fracturing of rock formations, reducing noise, dust, and structural damage while improving operational efficiency in confined or sensitive areas.

Pre-splitting Blasting

Pre-splitting blasting creates a controlled fracture plane by drilling closely spaced holes and detonating explosives sequentially to minimize damage to the surrounding rock, enhancing wall stability and reducing overbreak in mining operations. Non-explosive rock breaking techniques, such as hydraulic splitting or expansive chemical agents, offer safer and quieter alternatives but generally achieve lower efficiency and slower rock fragmentation compared to pre-splitting blasting in large-scale excavation projects.

Blasting vs Non-explosive rock breaking Infographic

industrydif.com

industrydif.com